Plumbing & Mechanical Top Stories

Most-viewed products from pmmag.com reveal that hybrid systems and jobsite efficiency are top of mind.

Read More

From first call to repeat customer

Loyalty doesn’t require expensive software or flashy marketing. It comes from consistent, thoughtful habits that show customers they are seen, heard, and cared for.

January 6, 2026

AHR Expo 2026 returns to Las Vegas

Demand for AI, electrification and mission-critical cooling prompts exhibitors to highlight connected technologies that simplify installation and improve long-term performance.

January 6, 2026

The Blue Collar Coach | Kenny Chapman

Reflect, Refocus, Reignite: A leadership reset plan for 2026

December 29, 2025

Top ten of 2025: The most-read articles on Plumbing & Mechanical

Our top stories of 2025, based on the number of unique pageviews.

December 23, 2025

Editorial Opinion | Kristen Bayles

Beyond the classroom: finding fulfillment in the trades

A personal look at the lessons today’s plumbing apprentices teach us about skill, pride, and opportunity.

December 19, 2025

Heating Perceptions | Scott Secor

The hazards of servicing old boilers

From crumbling wiring to failing antique controls, the cost and liability of servicing decades-old heating systems often outweigh the benefits.

December 19, 2025

Plumbing Apprenticeship

The enduring power of plumbing apprenticeships

Centuries-old training traditions still guide young professionals navigating a fast-changing industry.

December 17, 2025

The Glitch & The Fix: Zone 3 failure

Can you figure out why this boiler circulator failed?

December 16, 2025

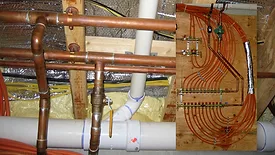

The future of jobsite piping: pre-fab and push-fit

As labor shortages and rising costs squeeze contractors, off-site fabrication and push-fit technology is transforming how plumbing systems are built.

December 15, 2025

Keep your content unclogged with our newsletters!

Stay in the know on the latest plumbing & piping industry trends.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing