Heating Perceptions | Scott Secor

The hazards of servicing old boilers

From crumbling wiring to failing antique controls, the cost and liability of servicing decades-old heating systems often outweigh the benefits.

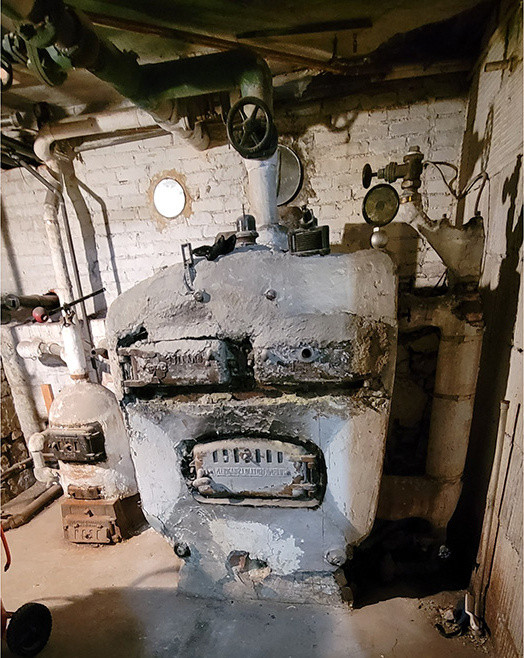

We occasionally receive requests to work on very old boilers. I also read on websites like HeatingHelp.com that there are still many of the older boilers still in operation throughout the United States and Canada.

As mentioned in past articles, when I started working for my father in the 1980’s, many of our residential and commercial customers had older boilers. “Older” back then was equipment installed in the 1920’s and the 1930’s. Middle aged boilers were installed in the 1940’s and 1950’s. “Modern” boilers were from 1960’s to 1980’s. Many of the steam distribution systems (piping, radiators, risers, etc.) were original to these systems, mostly from the 1910’s through the 1930’s.

Today, we still get calls about older systems. The potential customers often think their house or building is the oldest we have ever seen. I suppose people think every other building on their block has removed the old steam or hot water system and replaced it with something more modern. Most of the original steam systems in my area of NJ are practically all original, besides the boiler itself. Almost every week we see steam mains and steam risers that are about one hundred years old. The same is true of cast iron radiators.

A century-old legacy of steam and hot-water systems still exists across North America, but rising safety risks, obsolete parts, and mounting liability are pushing technicians to step away from aging equipment. Images courtesy of Scott Secor

We rarely work on boilers older than sixty years old these days. There are many reasons for this, including reliability, poor efficiency, dangerous flue gases escaping from the units, lack of parts and sometimes safety concerns.

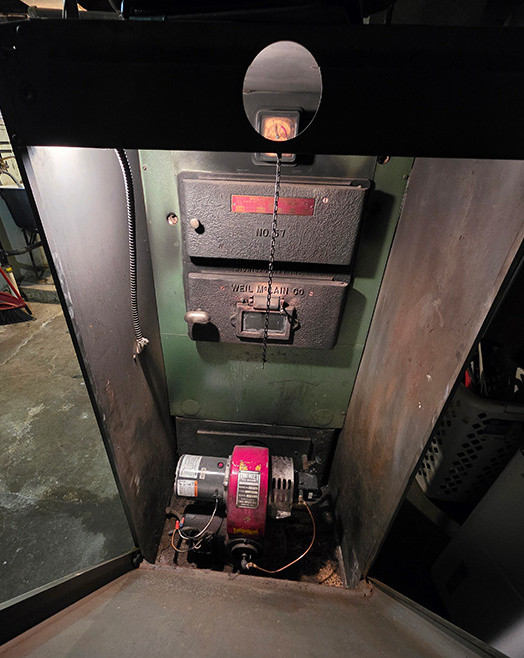

I can recall working on older boilers/burners and having insulation on the line voltage wires crumble in my hands. There were occasions that the insulation covering the old pancake style boilers landed on me and my toolbox when the burner started. I witnessed stack relays hang a few times, allowing raw fuel to enter the combustion chamber for an extended period of time, and finally igniting with a bang. Many of the older controls used Bakelite instead before plastic was widely used. While Bakelite was a great product, it does tend to break down after years of use, especially next to a hot boiler.

The oldest commercial boiler we regularly service was built in the 1930’s. This is a steel fire tube commercial boiler. We acquired the account in the 1980’s, and our subcontractors have retubed the boiler twice since then. Our welder had to replace a welded handhole a few years ago. We just had to resurface the manhole last year. We had to repair some of the refractory inside the boiler many years ago.

A few years ago, the low water cutoff/feeder from the 1960’s failed and we had to replace it. Unfortunately, the LWCO control was no longer available. As a result, we had to make some significant changes to the piping to accept the new LWCO. This steam boiler originally heated the building that was a public school. Since the 1980’s, it has been used as a private day care center. As far as I know, the building has never closed due to lack of heat. The owner understands how critical the boiler, burner and entire heating system are. He or his wife pay the bills within three days of receiving our invoices.

I can recall working on older boilers/burners and having insulation on the line voltage wires crumble in my hands. There were occasions that the insulation covering the old pancake style boilers landed on me and my toolbox when the burner started.

A few times a year during the heating season, we receive a call from a potential residential customer with an older boiler that they want us to look at. In many cases, there are so many problems we decide not to work on them. We are concerned with liability issues due to asbestos, flue gas leakage, clogged boilers, clogged chimneys, gas leaks, seventy-year-old gas valves, returns filled with sediment, antique controls failing, original relief valves, etc.

I suppose it is possible that any boiler that has been providing heat for the structure for the last one hundred years could last another century. Unfortunately, the repairs have become very expensive. Something as simple as replacing a float style low water cutoff could take almost an entire day. Replacing a steel nipple on a return at the boiler could actually rip the threads out of the cast iron boiler (yes, this has happened to us a few times.) When we see a rebuilt stack relay on an oil boiler, we cringe. When we see a boiler covered with a layer a few inches thick of insulation and no jacket, we get nervous. Some of the wiring I have seen on residential and commercial boilers likely never met the electrical codes. Swapping a simple circulator could become a nightmare when you have to deal with triangle shaped flanges that are spaced further apart than anything available.

These days, we avoid working on boilers older than fifty years old.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!