Commercial pipe support best practices: applications, materials and code compliance explained

Commercial construction presents unique challenges that make pipe support more complex than in residential work.

Installation practices determine whether pipe support performs as intended.

Pipe support plays a foundational role in the performance, safety and longevity of commercial plumbing and mechanical systems. Every system relies on proper support to maintain alignment, manage weight, control movement, and protect joints over time. In commercial buildings, where piping often runs long distances, serves multiple floors, and operates continuously, pipe support decisions directly impact reliability, maintenance requirements, and inspection outcomes.

Commercial construction presents unique challenges that make pipe support more complex than in residential work. Building size, system density, structural limitations and trade coordination all affect how pipe support should be applied, selected, and installed.

Understanding these factors helps contractors and engineers deliver systems that perform as intended throughout the life of the building.

Pipe support applications in commercial buildings

Pipe support applications vary based on system type and building layout. Plumbing, fire protection, HVAC and mechanical systems often share limited ceiling space, which increases the importance of proper support placement and coordination.

Drainage systems:

- Drainage systems require a consistent pitch to function correctly.

- Supports must maintain slopes across long horizontal runs, offsets and changes in direction.

- Even minor sagging can disrupt flow and increase the risk of blockages or backups, especially in high-use commercial environments.

- Vertical-to-horizontal transition points should be supported to help manage sudden weight changes and protect fittings during events such as system activation.

Pressurized systems:

- Pressurized systems rely on support to control movement and reduce stress at joints and fittings.

- Long pipe runs, vertical risers and equipment connections all introduce weight and movement that supports must manage.

Fire protection systems:

- Fire protection systems introduce additional load considerations.

- Vertical-to-horizontal transitions experience concentrated stress.

Structural elements:

- Structural elements such as beams, floor assemblies, and framing often dictate routing paths.

- Large HVAC ductwork often occupies priority space in commercial ceilings, forcing plumbing systems to adapt.

- Effective pipe support applications account for these constraints while maintaining system function and accessibility.

Selecting pipe support for commercial systems

Selecting pipe support involves more than meeting spacing requirements. Pipe material, system function, load conditions and environmental factors all influence support selection.

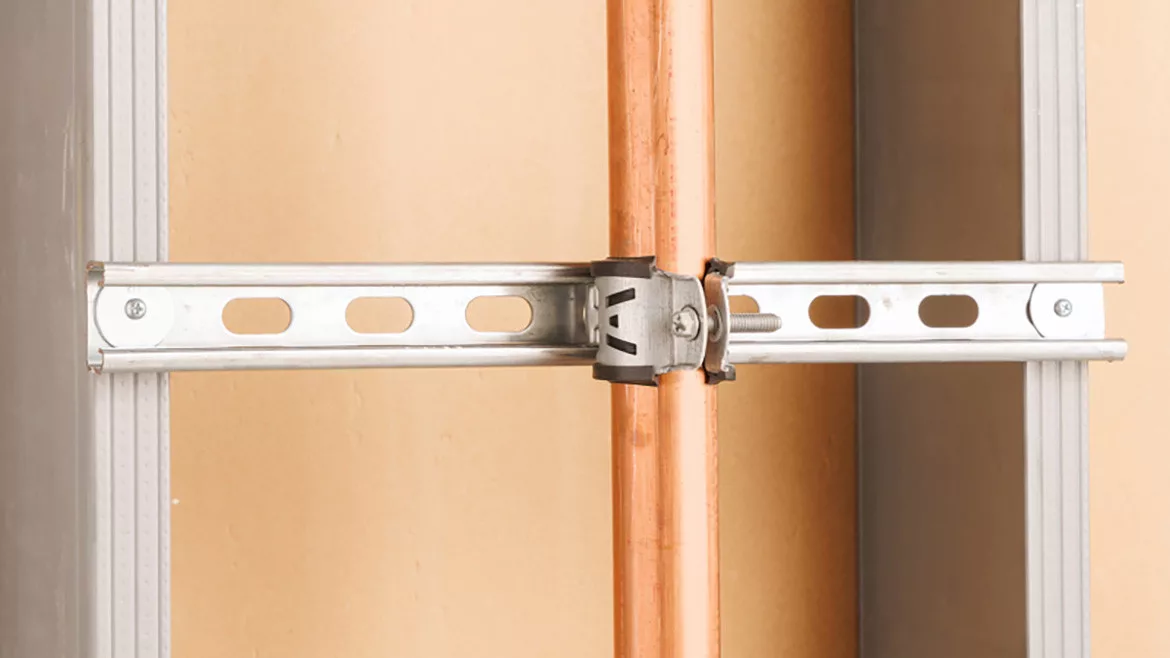

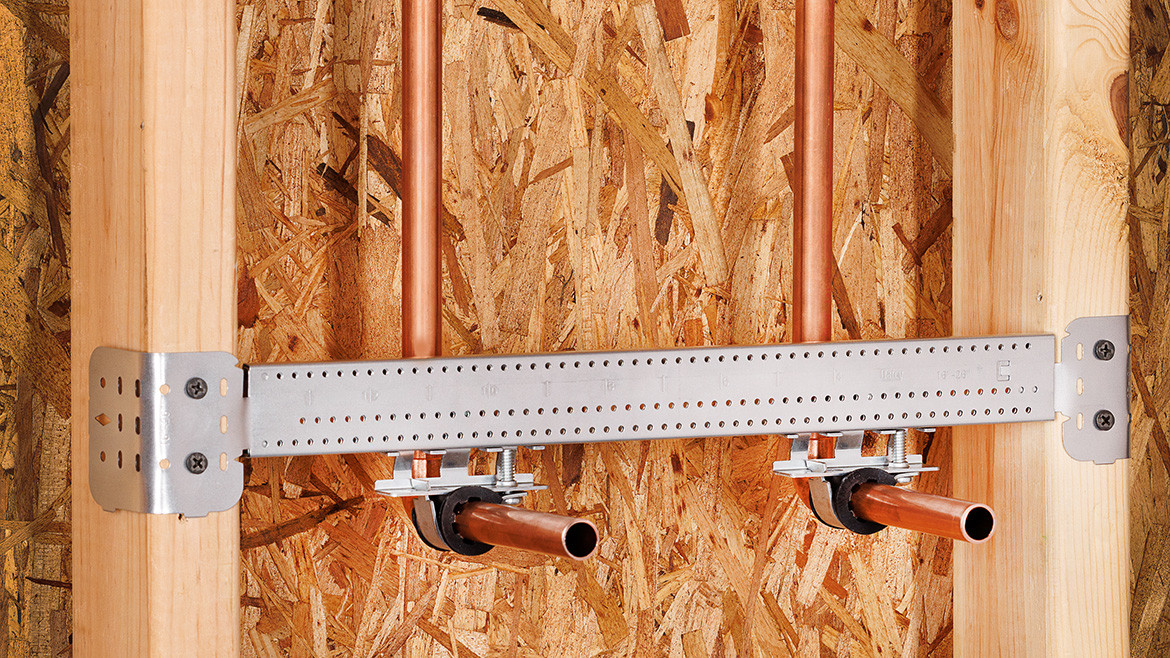

Piping systems rely on proper support to maintain alignment, manage weight, control movement, and protect joints over time. Image courtesy of Oatey Co.

Pipe material

Pipe material plays a significant role.

Copper piping, which remains common in commercial buildings, requires careful attention at support points. When copper pipe comes into direct contact with steel or other dissimilar metals, electrolysis can occur. This process leads to corrosion that weakens the pipe over time and increases the risk of leaks. The damage often develops gradually and remains hidden above ceilings or behind walls.

Supports with cushioned contact surfaces help prevent this issue by separating copper pipe from rigid metal components. The cushioning limits metal-to-metal contact, reduces abrasion caused by movement, and absorbs vibration. These characteristics help protect joints and fittings while also reducing noise transmission in occupied spaces such as healthcare facilities, multifamily buildings, and mixed-use properties.

Cast iron systems require close attention at couplings, which represent natural weak points. Rubber couplings depend on nearby support to manage weight. Large-diameter pipes can hold significant water during backups or heavy flow events. Supporting both sides of a coupling limits movement and reduces stress on the joint.

Flexible piping presents different challenges. Long unsupported runs place stress on fittings, increase movement, and generate noise. Proper spacing and secure attachment help control these issues and protect system connections.

Adjustability and installation efficiency

Support selection should also account for adjustability and installation efficiency. Systems with adaptable mounting points and adjustable spacing allow installers to maintain alignment when routing changes occur. Lightweight components and designs that reduce the number of installation steps help crews work efficiently in overhead and confined spaces. Modular designs that align multiple pipe runs support consistent layouts and simplify coordination in mechanical rooms and utility corridors.

Pipe support material

Accounting for pipe material compatibility during support selection helps reduce corrosion-related failures and extend the service life of commercial plumbing systems. Supports that meet fire-resistance and plenum requirements simplify compliance in commercial environments. Corrosion-resistant finishes and durable materials support long-term performance and reduce the need for replacement.

Installation best practices for commercial pipe support

Installation practices determine whether pipe support performs as intended. Design drawings often present pipe runs in ideal locations, but field conditions frequently require adjustments due to structural elements, framing conflicts, or previously installed systems. When pipe routes change, support plans must adapt.

Installers who understand why supports matter can make informed adjustments without creating weak points. Adjustable support systems help crews maintain alignment and spacing even when conditions change.

Plumbing, fire protection, HVAC and mechanical systems often share limited ceiling space, which increases the importance of proper support placement and coordination. Image courtesy of Oatey Co.

Best practices during installation include:

- Maintaining required spacing when pipe routes shift

- Adding support near joints, fittings, and transitions where stress concentrates

- Preserving pitch in drainage systems to protect flow

Efficiency also affects installation quality, particularly in overhead or congested spaces. Support designs that simplify placement help crews work accurately while maintaining consistency.

Pipe support features that support best practices:

- Supports that hold pipe in place during overhead installation, allowing one-handed placement

- Self-closing and snap-in engagement that reduces installation steps

- Modular alignment features that help organize parallel pipe runs

Coordination with other trades remains critical. Jobsite meetings help identify routing conflicts early and allow teams to adjust plans before installation progresses. Clear communication reduces rework and protects system performance in crowded ceiling spaces.

Code Compliance and Consistency

The IAPMO Uniform Plumbing Code and the International Plumbing Code establish minimum spacing and load requirements for pipe support. Following these standards promotes consistency across large projects and repeated layouts. Installations that rely on code-aligned practices produce predictable results and reduce variation between crews.

Code compliance supports safety, function and reliability. Uniform support placement improves inspection efficiency and simplifies future maintenance and system modifications. Consistency benefits installers, inspectors, and building owners alike.

Piping systems rely on proper support to maintain alignment, manage weight, control movement, and protect joints over time. Image courtesy of Oatey Co.

Avoiding common pipe support failures

Most pipe support failures stem from recurring issues such as missing supports, weak points at joints, or improper material contact.

- Sagging drainage pipe disrupts flow and increases the risk of backups.

- Unsupported pressurized pipe places stress on fittings and connections.

- Dissimilar metal contact leads to corrosion and eventual leaks.

- Long, unsupported runs increase movement and noise

Failures often occur in smaller commercial renovations where permits and inspections are skipped. Inspection requirements help identify deficiencies early and protect building occupants from avoidable risk.

Building systems that perform over time

Pipe support remains out of sight once ceilings and walls close, though its impact continues throughout the life of the building. Systems that rely on secure, adaptable and properly selected support perform more consistently and require fewer repairs.

Clear application, thoughtful selection and disciplined installation practices form the foundation of reliable commercial plumbing and mechanical systems. Attention to pipe support at every stage helps ensure systems operate safely and efficiently for decades.

FAQs

How should supports be applied to drainage and pressurized systems to prevent failures?

Drainage piping must maintain a consistent pitch across horizontals, offsets and direction changes. Supports should prevent sagging to avoid flow disruption and backups. In pressurized systems, supports must control movement and reduce stress at joints, fittings, vertical risers and equipment connections.

Selecting pipe support involves more than meeting spacing requirements. Pipe material, system function, load conditions and environmental factors all influence support selection.

What factors matter most when selecting supports for copper, cast iron, and flexible piping?

For copper, avoid direct contact with steel or dissimilar metals to prevent electrolysis and corrosion; use cushioned surfaces to reduce abrasion, vibration and noise. Cast iron systems require close support near rubber couplings to limit movement and joint stress, especially for large diameters holding significant water. Flexible piping needs proper spacing and secure attachment to minimize movement, stress at fittings and noise. Across all types, consider adjustability, modularity, corrosion-resistant finishes, and compliance with fire-resistance and plenum requirements.

What installation features and practices improve quality and efficiency on-site?

Use adjustable systems with adaptable mounting points and adjustable spacing to maintain alignment when routing changes in the field. Choose supports that hold pipe during overhead work for one‑handed placement, and self‑closing or snap‑in designs to reduce steps. Modular alignment features help organize parallel runs in corridors and mechanical rooms. Best practices include maintaining required spacing after route shifts, adding supports near joints, fittings and transitions where stress concentrates, and preserving pitch in drainage systems. Coordinate early with other trades to avoid conflicts and rework.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!