Home » Keywords: » hydronics

Items Tagged with 'hydronics'

ARTICLES

Renewable Heating Design | John Siegenthaler

Downstream details

Read More

Project Profile

ThermaCEILING radiant system provides net‐zero comfort in Connecticut ICF home

January 16, 2026

Hydronics Workshop | John Siegenthaler

What’s it capable of? (part 1)

Why accurate performance measurements are essential when evaluating an existing hydronic system for a heat pump.

January 9, 2026

The Glitch & The Fix: Zone 3 failure

Can you figure out why this boiler circulator failed?

December 16, 2025

Hydronics Workshop | John Siegenthaler

Injection mixing revisited: part one

Injection mixing remains one of the most adaptable and underutilized methods in hydronic system design.

November 17, 2025

Renewable Heating Design | John Siegenthaler

Elegance extended: How to use the homerun system of connecting heat emitters

November 12, 2025

Renewable Heating Design | John Siegenthaler

Using ratios to measure, compare and improve HVAC systems

Relating to ratios

October 15, 2025

The Glitch & The Fix: October 2025

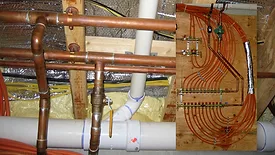

Hindsight - From complex loops to clean headers: simplifying for reliability

October 13, 2025

Hydronics Workshop | John Siegenthaler

How mismatched loads in a dual-temperature heat pump system can limit performance

Toggle time

October 8, 2025

EVENTS

Industry

4/10/14

Portland

Portland, ME

United States

Workshop: Hydronics for High Efficiency Wood-fired and Pellet-fired Boilers

IMAGE GALLERIES

PM’s Top 10 Most-Read Stories of 2018

These 10 most-read stories got the most hits from check valves to venting to leak detection on www.pmmag.com over the past year.

December 21, 2018

Keep your content unclogged with our newsletters!

Stay in the know on the latest plumbing & piping industry trends.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing