Articles by John Siegenthaler, P.E.

Hydronics Workshop | John Siegenthaler

Measuring net heat output and head loss in existing hydronic circuits.

Read More

The Glitch & The Fix: February 2026

Bewitched Btus: Understanding the hydraulic consequences of improper primary loop design

February 4, 2026

Renewable Heating Design | John Siegenthaler

One way to increase the ∆T of a distribution system

Downstream details

January 30, 2026

Hydronics Workshop | John Siegenthaler

What’s it capable of? (part 1)

Why accurate performance measurements are essential when evaluating an existing hydronic system for a heat pump.

January 9, 2026

The Glitch & The Fix: January 2026

The Glitch & The Fix: Geo-normous problems

Pairing a non-modulating geothermal heat pump with a multi-zone, low-mass radiant system introduces several avoidable issues.

January 7, 2026

The Glitch & The Fix: Zone 3 failure

Can you figure out why this boiler circulator failed?

December 16, 2025

Hydronics Workshop | John Siegenthaler

Injection mixing revisited (part 2)

Advanced ways injection mixing can manage temperature, protect equipment, and stabilize modern hydronic systems.

December 8, 2025

Hydronics Workshop | John Siegenthaler

Injection mixing revisited: part one

Injection mixing remains one of the most adaptable and underutilized methods in hydronic system design.

November 17, 2025

Renewable Heating Design | John Siegenthaler

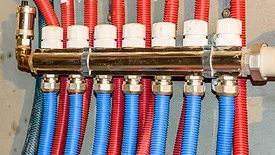

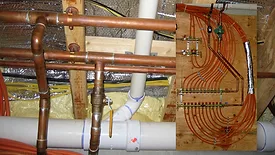

Elegance extended: How to use the homerun system of connecting heat emitters

November 12, 2025

Keep your content unclogged with our newsletters!

Stay in the know on the latest plumbing & piping industry trends.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing