Renewable Heating Design | John Siegenthaler

Transitions: What do I do about cooling? (Part 1)

Image courtesy of gerenme / iStock / Getty Images Plus

That’s got to be one of the most frequently-asked questions from potential customers who are convinced they want the benefits offered by modern hydronic heating, but at the same time don’t want to sweat it out in summer.

The answers to that question from some plumbing and heating contractors might be one of the following:

- "I know a guy…"

- "just throw in a couple ductless mini-splits,"

- "just turn on some fans for those few hot days."

Most of those answers are not "settling" from the potential customer’s standpoint. Most involve compromised comfort, higher cost, increased complexity, dealing with multiple installers, etc. In some cases the probable sale of a hydronic heating system is lost based on an inadequate response to the customers desire for cooling. Instead, that sale went to a company offering heating and cooling using a well-coordinated set of hardware devices for forced air delivery, and a single source solution for installation and maintenance.

It doesn’t have to be that way

The connotation that hydronics is good for heating but can’t provide cooling has been around for a long time. Even consumers who barely know what the word "hydronic" means, likely understand it as a mean of heating buildings.

Fortunately, our industry is at a point where the question "But what do I do about cooling?" can be answered, with confidence, and by the same hydronics professional offering heating.

The rapidly growing availability of hydronic-based heat pumps, whether air-to-water or water-to-water geothermal units, provide - at no additional cost - the potential source device for a chilled water cooling system. Modern air-to-water and water-to-water heat pumps that are developed for the HVAC market, (e.g., not those specifically intended for domestic water heating), all come with refrigerant reversing valves. All that’s required to turn them from a hydronic heat source into a chilled water source, is a relay contact closure from a control system. Combine either of these heat pumps with a central air handler and ducted delivery system and you get central cooling.

"What about fresh air?"

Regardless of the delivery system used for heating and cooling, low energy homes designed to increasingly stringent energy codes, have significantly lower rates of uncontrolled air leakage. Some energy codes, such as those currently in effect in New York State, mandate blower door testing of every new low-rise dwelling unit, and require a natural air leakage rate no higher than 3.0 air changes per hour at 50 Pascal pressure difference. If you’re planning to build a certified "Passive House," the maximum rate of uncontrolled air leakage, as determined by blower door testing, is 0.6 air changes per hour at 50 Pascals pressure difference.

At these low rates of natural air leakage air quality can be compromised, especially in homes where vapors or fumes are generated from cooking, smoking, candles, aerosol cans, lots of showers, or other activities involving solvents, cleaning chemicals, etc.

The common solution for providing proper indoor air quality while conserving as much energy as possible is a Heat Recovery Ventilator (HRV) or its "cousin", an Energy Recovery Ventilator (ERV).

HRVs allow heat exchange between an incoming stream of outside air, and a exiting stream of indoor air. When properly sized they can provide adequate rates of fresh air while recovering around 70% of the heat that would otherwise be carried outside by a simple ventilation fan.

ERVs do the same thing, but can also transfer some of the moisture from the air stream with the higher absolute humidity into the other air stream. This helps maintain indoor humidity levels in winter, and reduce inside humidity in summer.

HRVs and ERVs have evolved from devices that only a few home energy "fanatics" would use, to accepted best practice in energy efficient buildings. As of 2017, all new homes in Ontario Canada must include an HRV or ERV. Don’t be surprised if a similar requirement soon appears in model energy codes used in the US.

If you’re a mechanical contractor doing work in new homes you need to understand HRVs and ERVs, and equip your company to install them.

So why does a column that began by promoting the combined use of hydronics and heat pumps for heating and cooling, morph into a discussion on HRVs and ERVs?

Because putting all this together spells OPPORTUNITY!

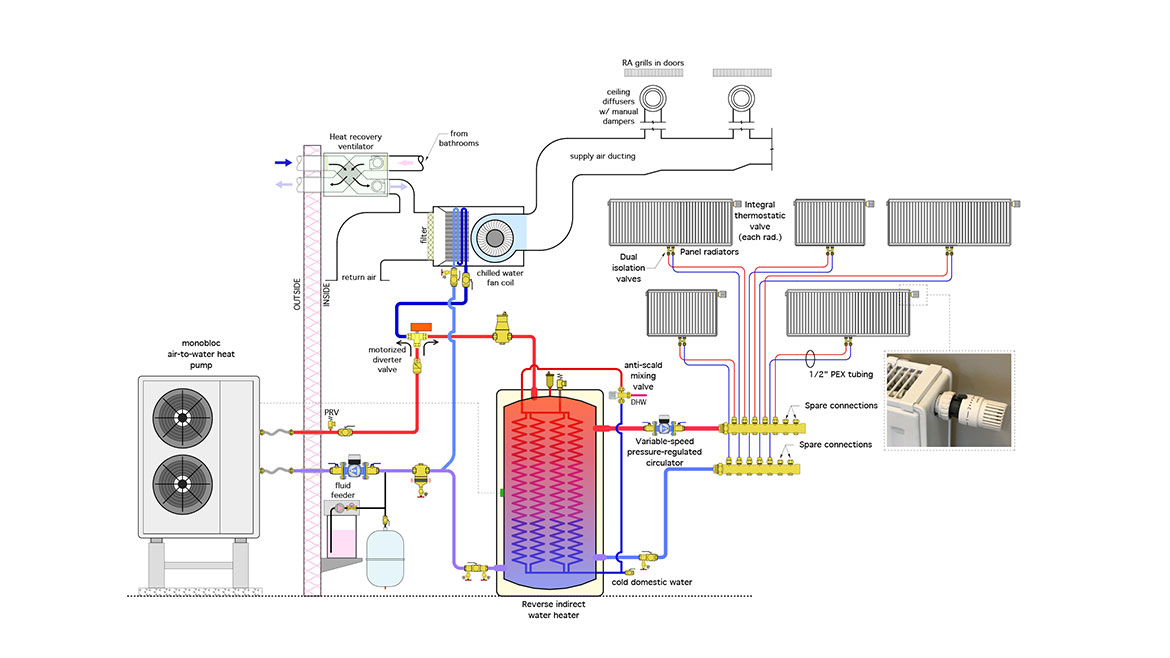

Take a look at the schematic in Figure 1.

This system uses a monobloc air-to-water heat pump as the source for heating, cooling, and domestic hot water. It also has a reverse indirect water heater and a heat recovery ventilator (HRV).

Flow from the heat pump enters the common port of a 3-way motorized diverter valve. In heating mode this valve sends the hot fluid to the reverse indirect water heater, which also serves as a buffer tank for a homerun distribution system supplying individually-controlled panel radiators. The heat pump monitors the temperature of the buffer tank, and maintains it between 115 and 125 ºF. Hot enough to fully heat domestic water to 110 ºF, as well as supply the design space heating load through appropriately sized panel radiators.

In cooling mode the diverter valve directs the chilled fluid from the heat pump to the coil of an air handler. The blower in the air handler operates to move cooled and dehumidified air through ducting and into the condition spaces though several ceiling diffusers.

Fresh air from the HRV is injected into the return side of the air handler. "Stale" air collected from the bathrooms passes through the HRF, where it transfers some of it heat content to the incoming fresh air stream before being exhausted outside.

The ECM blower motor in the air handler has been configured to operate at a relatively low flow rate whenever the HRV is operating. That flow rate should be slightly higher than the air flow rate from the HRV, ensuring that the fresh air stream passes through the air handler and is distributed to the building.

When the system goes into cooling mode, the blower speed is increased to a nominal 350 CFM per ton (12,000 Btu/hr) of cooling capacity of the air handler’s coil.

These speed changes conserve electrical input to the blower motor when it’s only operating for ventilation. They also ensure that the air handler provides adequate latent and sensible heat transfer when operating in cooling mode.

The changeover

Heat pumps cannot simultaneously operate in heating and cooling mode.

So what happens when a call for cooling comes at the same time the heat pump is raising the temperature of the buffer tank to ensure adequate DHW delivery? Or what happens when the system is operating in cooling, someone takes a long shower, and the buffer tank temperature drops to or below the "ON" setting of the system’s controller?

Think about those questions. How would you propose handling them? We’ll get into the specifics on one way to handle this in next month’s column.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!