Preventing sprinkler freeze failures starts long before the cold arrives

Why clearly defining heated envelopes, coordinating insulation and choosing the right dry technologies are essential to reliable fire protection in cold conditions.

Cold-weather events continue to expose weaknesses in sprinkler system design and installation. When sprinkler piping freezes, the resulting consequences can be grave: water damage, operational disruption and loss of fire protection when it is needed most. These failures are frequently attributed to extreme weather, but most stem from oversights in controlled conditions, such as unclear heated boundaries, improperly installed insulation that isolates piping from heat and incorrect application of dry sprinkler technology. With careful planning and coordination, freeze-ups can be significantly reduced, even during severe cold weather events.

Designing to the heated envelope: Keep piping in verified conditioned zones

Freeze failures can often be traced back to installation mistakes made when the heated envelope was assumed rather than confirmed. In most situations, wet piping should only be installed in spaces that can reliably maintain 40 degrees Fahrenheit or higher. NFPA 13 does allow wet systems in spaces below 40 degrees Fahrenheit if a licensed professional engineer performs heat-loss calculations demonstrating the system won’t freeze under these conditions. This path requires careful analysis and is not commonly preferred in practice.

Mechanical rooms with outdoor air intake, stairwells and vestibules, loading dock transition corridors, ceiling cavities, soffits and intermittently heated large spaces like warehouses and gyms are often exposed to below freezing temperatures. If these areas are not evaluated and documented properly, sprinkler pipes routed through them are vulnerable.

The building design team is responsible for defining and documenting the heated envelope. Fire protection contractors rely on that information at installation. When boundaries are not explicitly defined, contractors are left to make thermal decisions in the field, which increases risk.

Identifying the heated envelope should occur early in the sprinkler system design and be reviewed alongside mechanical and enclosure details. Transitions at roof decks, soffits, and perimeter ceilings deserve particular attention. In my years in the fire protection industry, I’ve seen this challenge impact projects in different ways. One year, I worked with a contractor tasked with an emergency repair after a branch line installed in a cavity assumed to be conditioned froze during a cold spell. Moving it a few inches further inside the conditioned space would have prevented it. In another instance, a contractor asked whether a wall cavity counted as heated, highlighting why this information needs to be clearly documented on the plans rather than left to interpretation.

Clear delineation on drawings helps ensure freeze-prevention decisions are made at the design stage rather than on a lift in the field.

Insulation and heat transfer: Coordinate to ensure pipes benefit from heat

Insulation preserves heat. It does not generate it. Freeze failures can occur when insulation unintentionally isolates piping from the heated space. Placing insulation between the pipe and the heated space, or wrapping it so tightly that heat cannot reach the pipe when tenting the pipe, can create conditions where piping freezes even inside a nominally conditioned zone.

Since fire protection piping must be installed before insulation, coordination is essential. Insulation should be placed on the cold side so heat from the conditioned space can reach the pipe. Transition points, roof-to-wall interfaces and ceiling cavities should be reviewed to ensure insulation is continuous to keep cold air out while at the same time not separating sprinkler system piping from the heated space.

Installers work in tight spaces and often at later phases of construction, so clarity and communication reduce uncertainty and help ensure field conditions do not undermine design intent.

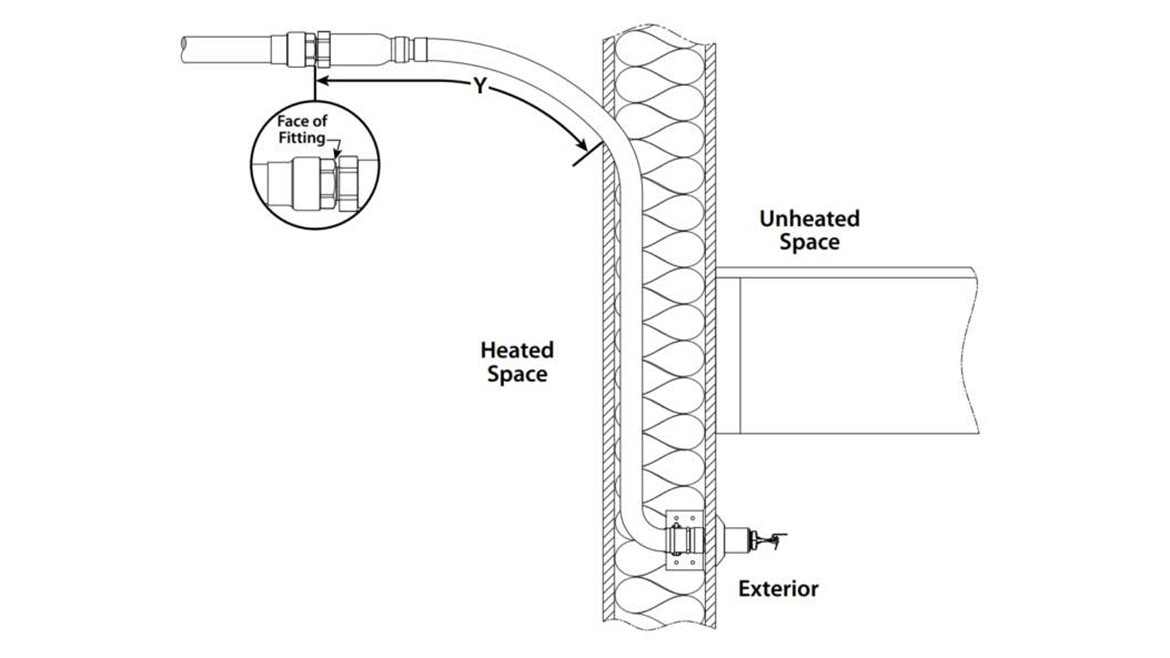

Diagram showing a flexible dry sprinkler installation where the connection remains within the heated space. Routing flexibility allows more of the hose to stay warm, reducing freeze risk in unconditioned areas. Image courtesy of Victaulic

When wet systems are not appropriate: Choosing the right alternative

In unconditioned spaces, wet systems are not appropriate, and contractors must use other system solutions. Alternatives include dry pipe systems, dry preaction systems, listed antifreeze solutions within NFPA volume limits, and listed heat-trace systems.

Every approach carries installation and maintenance considerations. There is no universally low-cost alternative to having systems in a heated space. Dry systems require additional testing and maintenance, antifreeze systems are limited and must be listed, and heat-trace must be listed for fire protection use and installed correctly. In many scenarios, if any approach triggers the need for a fire pump and tank, that option becomes significantly more expensive and is typically less practical than others.

The goal is to select the simplest solution that reliably protects occupants and property within project constraints.

Dry sprinklers and barrel length: Meeting envelope-based requirements

Dry sprinklers extend wet systems into colder zones by creating an insulated path between the heated space and the sprinkler. Their performance depends on correctly sizing the exposed barrel length so freezing temperatures do not reach the water supply connection.

Required length is based on interior and exterior temperatures and the precise location of the heated envelope. Dry sprinklers can be FM approved up to 36 inches in length and UL listed up to 48 inches in length if they are hard barrel type dry sprinklers, and up to about 58 inches for certain flexible dry sprinklers. The objective is consistent across listings: cold traveling up the metal barrel must have time to warm before it reaches water connections. Undersizing the length of the barrel in the heated space increases the risk of cold migration and freeze impairment.

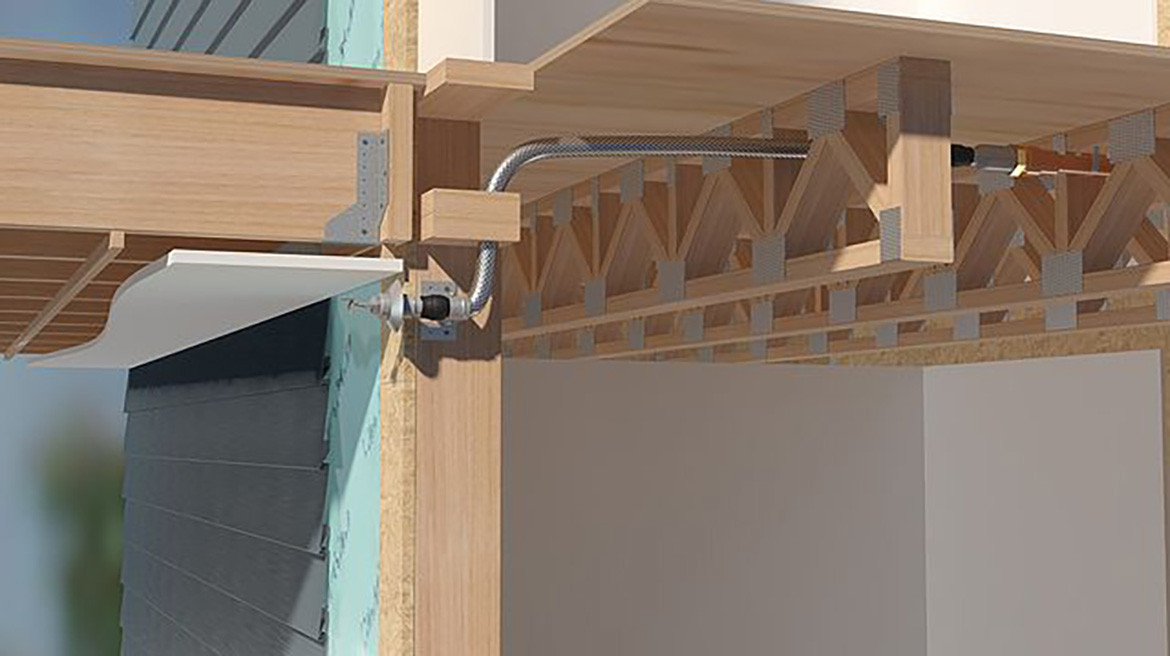

Flexible sprinklers like the Victaulic VicFlex Series VS1 Dry Sprinkler provide added freeze protection in areas where piping transitions between heated and unheated spaces. The sprinkler’s flexible design helps keep more of the product within the heated envelope, reducing the risk of freeze-related failures when cold seeps in. Image courtesy of Victaulic

Flexible dry sprinklers: Managing field variability

Flexible dry sprinkler technology helps maintain envelope integrity in tight conditions. Since flexible dry sprinklers can bend around building elements, more of the hose can remain inside confirmed heated space. This also increases the warm buffer length before any cold exposure reaches the connection.

Additionally, flexibility provides installation tolerance. If field routing shifts slightly during construction, flexible dry sprinklers reduce the need for rerouting or rework and maintain protection at thermal boundaries. This combination of placement flexibility and added thermal path makes flexible dry sprinklers an effective solution in challenging envelope conditions.

Looking forward: Tighter envelopes and improved freeze protection

Building envelopes continue to tighten and air sealing continues to improve, which stabilizes interior conditions and makes freeze protection more predictable. Reliable performance in these environments still depends on clear envelope definition, disciplined routing and appropriate use of dry technologies. As listed heat-trace, antifreeze, dry system, and dry sprinkler solutions continue to evolve, systems will become even more robust at transitional and cold boundaries.

Ensuring system performance in freezing conditions

Dependable freeze protection follows a consistent approach: define the heated envelope clearly, keep wet piping inside conditioned space, coordinate insulation so heat reaches piping, and use dry systems, listed antifreeze or listed heat-trace where temperatures cannot be maintained. Selecting the correct dry sprinkler barrel length and using flexible solutions near thermal boundaries further strengthen system reliability.

Teams that master these fundamentals are not only better equipped to prevent freeze damage but also streamline coordination and delivery as building performance expectations continue to rise. Effective freeze protection is ultimately about clarity, communication and thoughtful application of proven methods.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!