New trends in corrosion and freeze protection for resilient fire sprinkler systems

New product innovations present solutions to common pitfalls.

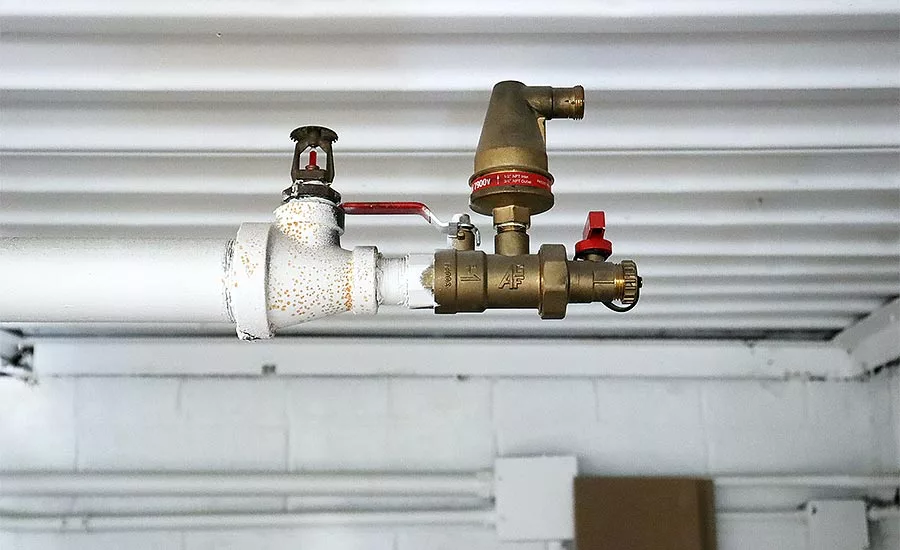

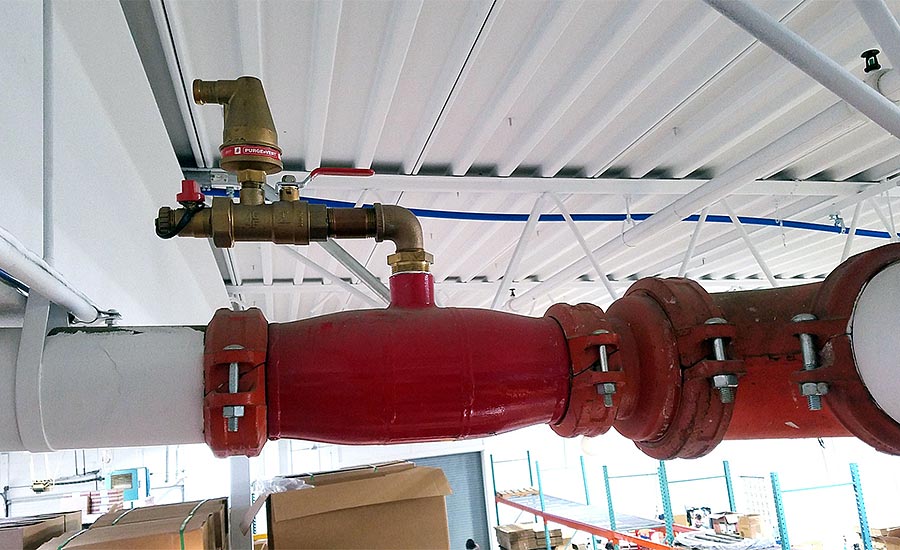

AGF’s PURGEnVENT Model 7900 Automatic Air Vent (AAV) is a 1-inch isolation ball valve, barrel strainer, air vent and purge valve that helps prevent corrosion by automatically releasing trapped air in wet fire sprinkler systems. It meets NFPA 13 code that requires a single air vent on each wet pipe sprinkler system utilizing metallic pipe. The patented design automatically vents air without leaking, eliminating the need for drip pans or drain lines.

How can engineers and contractors design wet fire sprinkler systems equipped to prevent corrosion and dry systems equipped to prevent freezing? That has long been a question central to code requirements and new product development.

Recent innovations have presented a few possible answers to that question. By including new products such as air vents, self-draining auxiliary drains in heated cabinets and flood elimination devices, engineers and contractors can design systems better equipped to protect themselves against the common pitfalls of corrosion and freezing.

Adopting code to prevent corrosion

In wet pipe fire sprinkler systems, the combination of water, metal and oxygen from trapped air creates corrosion. While corrosion-caused pinhole leaks in pipes can result in thousands of dollars in property damage and repair cost, the real concern is it can also cause obstructions that impair system performance and put lives at risk. Periodic internal inspections are required by NFPA 25 to check for obstructions to prevent this. Ironically, the fresh water and trapped air that is introduced into the system during those inspections will actually increase the rate of corrosion. If the check for corrosion-caused obstructions leads to more corrosion, what can be done to stop the cycle?

Long-term studies by the National Fire Prevention Association and Factory Mutual have found that trapped air in wet pipe sprinkler systems is a major contributing factor of corrosion. Venting any amount of air was found to reduce the amount of resulting corrosion. Based on those studies, the 2016 edition of NFPA 13 adopted the requirement for air vents as part of the main text. It requires a single manual, automatic or another approved air vent to be located near a high point on each metal wet pipe sprinkler system.

Adopting devices to prevent corrosion

Manual air vents are the most economical and basic way to fulfill that code requirement and prevent corrosion. They vent air while a system is being filled. Traditional manual vents are opened when the system is filled and closed when water reaches the vent to prevent overflow. This requires an extra person to watch the valve and close it at the right time. At least one manual vent currently on the market includes a ball check to remove the need for an extra person. When the water reaches the valve, the ball check will prevent it from overflowing. When the system is full, the vent should be closed.

Automatic air vents are the most effective at preventing corrosion because they vent air while the system fills and automatically continue to vent air as the system settles or internal pressures fluctuate. Some versions currently on the market have a history of spitting, and as a result, include redundancy, drain lines, or drip pans — which are not required by code — to collect expelled water.

Other manufacturers have introduced new designs specifically to address the needs of wet sprinkler system vents, and as a result, have created products that have addressed these flaws. Automatic air vents also come with many installation options to make retrofitting them to existing systems simple.

Some people think an inspector’s test valve can be used as an air vent, but it is not an effective option for air venting. An inspector’s test and drain valve cannot sit at both the high point of the system to facilitate venting and the low point to facilitate drainage. Plus, when the system is filling, the drain legs fill before the main pipes and the inspector’s test valve gets cut off before most of the air can be exhausted.

New innovations are bringing solutions like air vents and auxiliary drain accessories to the market. Many of these products are easy to retrofit onto existing systems, so the benefits are not limited to future systems.

New innovations to prevent freezing and flood damage

As unexpected freezing weather in the Southeast proved this year, freeze damage can devastate a facility and freeze prevention is vital for fire sprinkler systems. On dry pipe systems, auxiliary drains are required to collect condensation that accumulates in the pipes. When freezing temperatures hit, drains that have not been emptied can freeze and break. This trips the dry valve and sends a fully pressurized flow of water to the broken drain. A fully open, one-inch pipeline can spill out 50 to 70 gallons of water a minute depending on available system pressure. That flow can cause thousands of dollars in facility damage and system repair costs, along with building occupant displacement and additional owner liability.

To prevent freezing altogether, consider upgrading the auxiliary drains. Adding water detector alarms to drum drips allows maintenance personnel to get an alert when the unit needs to be emptied. With proper maintenance, this is a simple way to prevent freezing. For more extensive freeze protection, facilities are choosing heated auxiliary drain cabinets. These locking cabinets are insulated and contain thermostatically controlled energy-efficient heaters. Some of these cabinets even include features that allow them to self-maintain or operate automatically.

Stopping the flood

If constant vigilance and the required auxiliary drain maintenance necessary to prevent a freeze and break is not an option, then a building owner might consider a product designed to minimize the impact of a broken auxiliary drain. A new product has been recently introduced to eliminate the flooding that would result from an auxiliary drain failure. As previously stated, a broken auxiliary drain can spill 50 to 70 gallons a minute. Most often, systems break when temperatures dip below freezing in the middle of the night, so it usually takes time for someone to realize there is a problem, or the fire department to respond to a system that has failed and come shut it down. Even if it only takes 10 minutes, that means 500 to 700 gallons of water have been dumped into the facility in that time.

Flood elimination devices sit above the inlet of the auxiliary drain and do not affect normal auxiliary drain operation. When the fully pressurized flow triggered by a tripped dry valve activation hits one of these devices, it senses the sudden pressure and restricts the flow of water to only eight ounces a minute. In 10 minutes, that would be less than a gallon versus up to 700 gallons from an unrestricted flow. The auxiliary drain will need to be repaired and the system reset, but this minimizes the damage to the building and inconvenience to tenants.

In conclusion

Corrosion and freezing temperatures threaten the stability of wet and dry fire sprinkler systems in facilities around the world. Luckily, new innovations are bringing solutions like air vents and auxiliary drain accessories to the market. Many of these products are easy to retrofit onto existing systems, so the benefits are not limited to future systems. Although corrosion and freezing temperatures are nothing new, these innovations could bring a new chapter of simplified maintenance and increased reliability to wet and dry fire sprinkler systems.

Photos courtesy of AGF.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!