Radiant Comfort Report Spring 2025 Edition

Best Practices for performance, comfort and longevity

Mastering radiant installation

Proper spacing, routing, and circuit length are all essential for delivering even heat and avoiding long-term issues. Image courtesy of IAPMO and Legend Valve

As radiant heating and cooling systems continue to grow in popularity for their superior comfort, energy efficiency, and quiet operation, the importance of proper system installation cannot be overstated. A poorly installed system—no matter how advanced its components—can fall short of expectations, leading to hot and cold spots, energy waste, or costly callbacks. At this year’s AHR Expo in Orlando, Florida, William J. Werthman, Hydronics Business Development Manager at Legend Valve delivered a high-impact session titled Installation Practice and Guidelines, offering a clear roadmap for delivering high-performance radiant systems across a range of applications.

Drawing from decades of field experience, Werthman’s presentation covered everything from tubing layout and flooring compatibility to manifold selection, zoning, and concrete pouring practices. The insights presented serve as a comprehensive reference for contractors, distributors, manufacturers, and design professionals who want to elevate the quality and reliability of their radiant projects.

Wet vs. dry radiant systems: Choosing the right method

Werthman began by outlining the two fundamental approaches to radiant hydronic installation: wet systems and dry systems. Wet systems, often referred to as high-mass systems, typically involve embedding PEX tubing into a concrete slab or lightweight overpour. These systems benefit from the slab’s thermal inertia, providing long-lasting, even heat. However, they come with longer response times and additional structural loading considerations. Common configurations include slab-on-grade, suspended slabs, and overpour systems using gypsum or lightweight concrete.

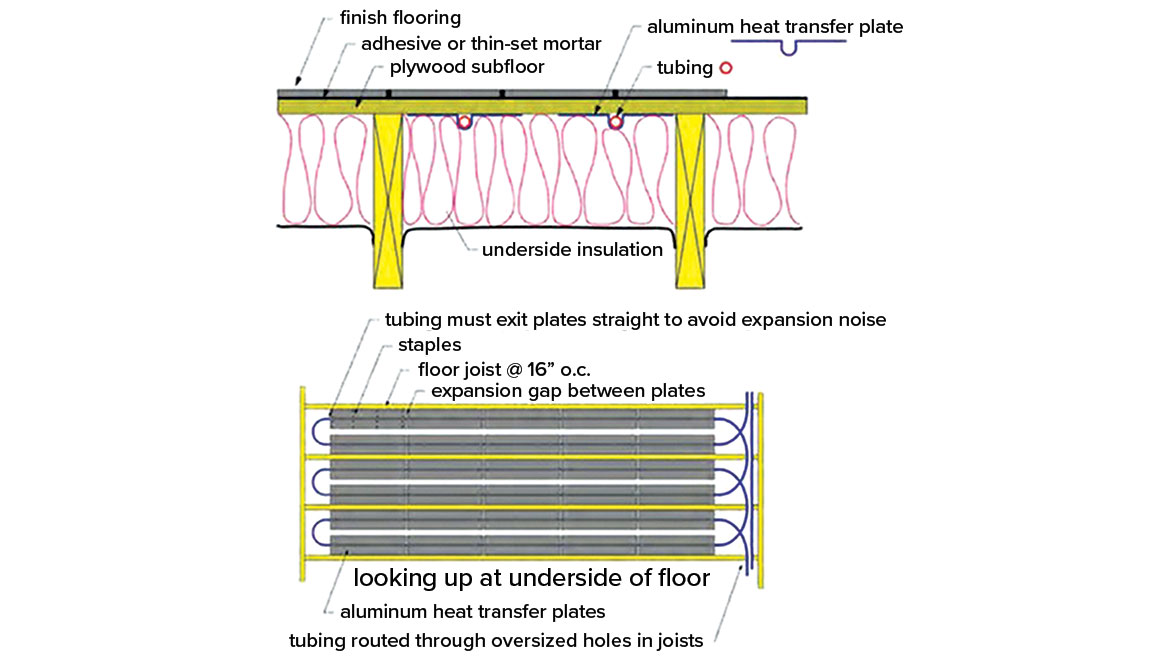

Dry systems, or low-mass systems, are gaining traction for their faster response times, lower weight, and easier zoning. They are ideal for renovations, upper floors, or any application where concrete pours are undesirable. These systems use heat transfer plates to conduct heat from the tubing to the flooring surface and are typically installed either in joist bays (staple-up) or above subfloors using panelized “sandwich” methods.

The choice between wet and dry installation methods depends on project goals, structural limits, installation timeline, and client expectations. Werthman emphasized that understanding the distinct behavior of each system is critical to achieving the desired comfort and energy performance.

Floor coverings: Design with the surface in mind

Radiant professionals understand that the floor covering is the final heat emitter and each material presents unique thermal and structural considerations. Werthman broke down best practices for several popular surfaces.

Tile and Stone, prized for their excellent heat transfer characteristics, remain a top choice for radiant systems. However, to avoid cracking, the substrate must be properly prepared and allowed to cure before the system is activated. Werthman recommended adhering to Tile Council of America (TCA) guidelines, using crack suppression membranes, and allowing 7 to 28 days of curing time before system operation.

Hardwood floors, while aesthetically appealing, are hydroscopic and prone to dimensional changes with temperature and humidity. Narrow strips (3"–3.5") of kiln-dried, quarter-sawn wood are preferred for stability. Installation moisture content should be between 7% and 10%, and subfloor humidity should not differ by more than 4%. Maintaining indoor humidity between 35% and 50% helps preserve floor integrity. Werthman also noted that bamboo, a grass-based composite, often performs better than traditional hardwoods and carries a slightly higher R-value (0.72 for ¾" bamboo versus 0.65 for ¾" oak).

Carpet, while less conductive than tile or wood, can be used if the system is designed with carpet in mind. The combined R-value of carpet and pad should not exceed 2.0. Radiant rated slab pads are preferred, while bonded urethane and prime urethane perform poorly. Werthman provided R-value examples for various carpet types, underscoring the importance of checking flooring specs during the design phase to ensure heat output is sufficient.

Tubing layout: Details that define performance

A core part of Werthman’s presentation focused on pipe layout guidelines, with a firm emphasis on consistency, planning, and documentation. Proper spacing, routing, and circuit length are all essential for delivering even heat and avoiding long-term issues.

Typical spacing for residential systems ranges from 6" to 12", while commercial installations may stretch to 18" or more. Tubing should be routed with the hottest water near exterior walls or high-heat-loss areas. Loop lengths should be sized according to tubing diameter: up to 250 feet for 3/8", 330 feet for 1/2", and up to 500 feet for 1" pipe.

Werthman recommended equalizing circuit lengths within the same zone to balance output and reduce flow discrepancies. Installers should avoid tight bends, overlap, and routing under walls. Tubing should be spread out as close to the manifold as possible and installed using tubing bend supports. Accurate as-built documentation is critical—recording layout details and deviations ensures future serviceability and simplifies troubleshooting.

Wet system best practices: Concrete and overpour considerations

For concrete slab systems, tubing is often tied to rebar or mesh and located near the slab’s bottom third, though tubing tied to insulation board with staple guns is common for radiant-only slabs. Thermal performance is greatly influenced by tube depth, slab thickness (typically 4"–8"), and insulation placement. Perimeter and vertical edge insulation are essential to reduce heat loss.

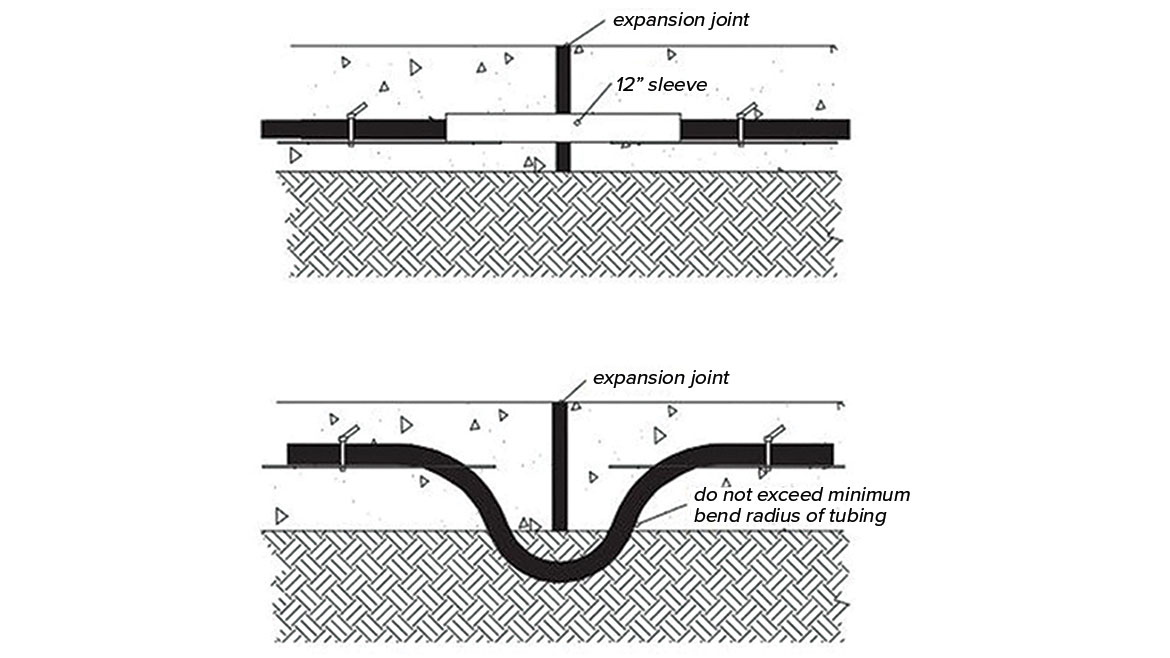

Special attention should be paid to expansion joints and slab cuts. Tubing must be protected with sleeves through the expansion joints, and crossing these joints should be minimized to prevent stress fractures.

For overpour applications, Werthman noted that tubing is laid over a subfloor and covered with a thin layer (typically 1.25"–2") of lightweight concrete or gypsum. These systems require attention to additional floor loading (10–20 psf), floor height transitions, and vapor barrier placement. When working with gypsum, the subfloor may need to be sealed to ensure bonding, and pouring should accommodate room dimensions, wall locations, and cabinetry.

Image courtesy of IAPMO and Legend Valve

Image courtesy of IAPMO and Legend Valve

Dry System Techniques: Transfer Plates and Joist Spaces

Dry systems use metallic heat transfer plates to spread heat across the subfloor surface. Werthman discussed both stamped and extruded plate options, favoring extruded aluminum plates for their durability and performance. Plates should be spaced with 1/8"–1/4" gaps and installed using pre-drilled holes in the heat transfer plates.

In joist bay applications (staple-up), tubing is placed beneath the subfloor with no plates, and insulation with a reflective surface is installed at least 2" below the tubing. Bubble foil wrap or foil-faced batt insulation is preferred to direct heat upward. These systems provide fast response times, are lightweight, and can be installed without coordination with concrete crews, making them ideal for remodels and tight schedules, although they typically require higher water temperatures.

The choice between wet and dry installation methods depends on project goals, structural limits, installation timeline, and client expectations. Image courtesy of IAPMO and Legend Valve

Design considerations: Zoning, manifolds and water temperature

Werthman emphasized that effective system design involves balancing comfort, control, and efficiency. Zoning is essential—especially in homes with varied room sizes and solar exposures. Designers should aim to avoid running tubing loops across multiple rooms or under walls, as this results in uneven heating. Instead, loops should be confined to individual rooms, allowing for actuator control and room-by-room zoning if desired.

Manifold selection matters as well. Contractors often try to reduce upfront costs by assembling “homemade” manifolds, but Werthman warned that the labor cost, risk of leaks, and lack of warranty can offset any savings. Full-featured manifolds with built-in isolation valves, flow meters, and standardized ports simplify installation, improve performance, and ensure long-term serviceability.

Using design software allows installers to properly size loops, set accurate water temperatures, and verify balanced flow across circuits. For example, one design case presented showed a simple 10-loop slab radiant layout requiring just 106°F water, but when broken into zones with varied loads, the software adjusted output to 121°F to satisfy the highest-loss space.

Mechanical room and system integration

Mechanical room practices were not left out of Werthman’s talk. He advocated for the use of hydraulic separators (such as the HS-808), which decouple boiler and zone pump circuits, improve air and dirt separation, reduce installation footprint, and simplify piping. These devices streamline boiler swaps and reduce the risk of call-backs due to flow imbalance or trapped air.

Werthman also stressed the importance of smart layout within mechanical rooms. Poor manifold placement can lead to overheated mechanical spaces due to a high concentration of return tubing. Remote manifold placement and thoughtful routing help distribute control and improve comfort.

Above all, Werthman’s message to radiant professionals was clear: details matter. Whether selecting tubing, designing loops, or installing manifolds, the long-term success of a radiant system hinges on thoughtful planning, proper materials, and skilled installation.

For contractors, that means following guidelines and using tools that improve precision and efficiency. For dealers and distributors, it’s about offering high-quality, compatible products and educating customers. Manufacturers are tasked with providing systems that support flexible, reliable installation. And for designers, every decision—from flooring to zoning—has an impact on performance.

Radiant systems are more than just tubing in a slab. When executed with care, they are among the most comfortable, efficient, and enduring climate control systems available. Werthman’s presentation at AHR 2025 offered a blueprint for excellence—one detail at a time.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!