Renewable Heating Design | John Siegenthaler

Versatility in direct-to-load systems, part one

Going direct.

Image Source: adventtr / iStock / Getty Images Plus

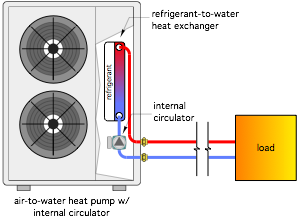

One of the latest design approaches for air-to-water and water-to-water heat pumps is called “direct-to-load” piping. It’s based on the ability of a inverter-driven scroll compressor to operate over a wide range of speeds, and to handle on/off cycling when necessary, without the frequent inrush current demands associated with short-cycling a fixed speed compressor. The concept of direct-to-load piping using an air-to-water heat pump with it’s own internal circulator is shown in figure 1.

It doesn’t get much simpler than this. No buffer tank, no hydraulic separator, just connect the two pipes from the heat pump to the two pipes leading to the distribution system.

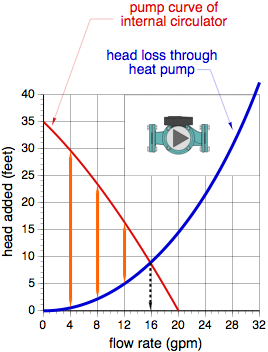

What’s available: Because a single circulator is driving flow through the heat pump as well as the distribution system, it’s important to evaluate the flow and head that’s available to that distribution system.

The “net” head available for the distribution system is found by plotting the head loss curve of the heat pump and the pump curve of its circulator on the same graph, then determining the difference between the head added by the circulator and the head loss curve of the heat pump. Figure 2 illustrates the concept.

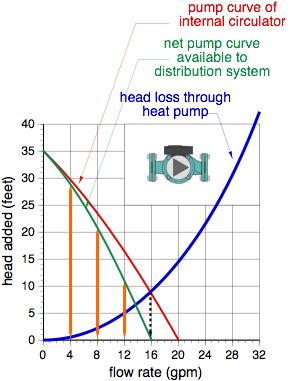

The orange vertical lines represent the “net” head available to the distribution system, (e.g., the head created by the circulator minus the head lost through the heat pump). The black dashed line dropping from the point where the pump curve crosses the head loss curve is the point where the net head available to the distribution system is zero. If the lower end of each orange line is moved down to the horizontal axis, and a curve is drawn smoothly through the upper end of those lines, that curve is the “net” pump curve available to the distribution system. The green line in Figure 3 shows an example.

Notice that the net pump curve is “steeper” than the pump curve of the circulator alone. This isn’t necessarily a problem when the heat pump is matched with a distribution system that has relatively high head loss at modest flow rates. Examples include a system with radiant panel circuits connected to a manifold station, or 2 or 3 similar manifold stations all operating as a single zone.

Notice that the net pump curve is “steeper” than the pump curve of the circulator alone. This isn’t necessarily a problem when the heat pump is matched with a distribution system that has relatively high head loss at modest flow rates. Examples include a system with radiant panel circuits connected to a manifold station, or 2 or 3 similar manifold stations all operating as a single zone.

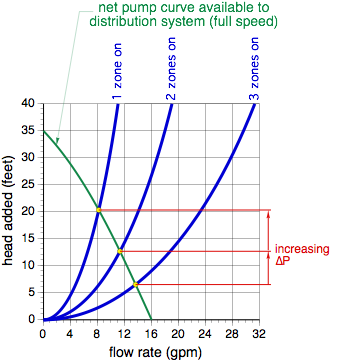

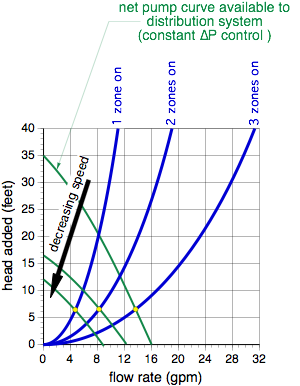

However, steep pump curves are not ideal for systems that use valve-based zoning. When a zone closes the differential pressure on the zones that remain open increases, which increases the flow rate in those active zones a shown in figure 4.

This undesirable situation can be minimized by using is a variable-speed circulator. By reducing the speed of the circulator as zones close off it’s possible to hold a relatively constant differential pressure across all active zones a shown in figure 5.

Some hydronic heat pumps are equipped with variable speed circulators. They typically control circulator speed based on the temperature differential across the heat pump. This differential is somewhat correlated to load, and with how many zones are active.

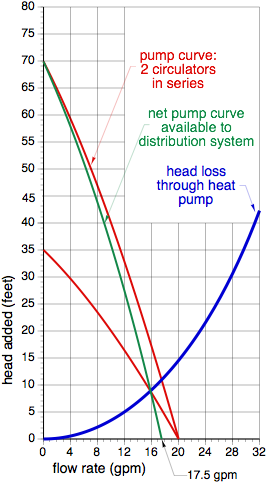

When one isn’t enough: If the internal circulator supplied with the heat pump cannot produce the flow and head required, it’s possible to add a second identical circulator in series with the heat pump as shown in figure 6.

Combining two identical circulators in series effectively doubles the head available at every flow rate, compared to a single circulator. The ‘net’ pump curve would be the curve for two circulators in series minus the head loss through the heat pump, which is shown as the green curve in figure 6. This is a very steep net pump curve. If this configuration is to be applied with valved-based zoning variable speed control is crucial to prevent large changes in differential pressure and associated changes is flow as the zone valves open and close. The second circulator can be speed controlled in parallel with the circulator inside the heat pump.

What’s next? There’s more versatility in direct-to-load systems than simply piping one heat pump to a load. Next month we’ll cover details for adding an auxiliary boiler.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!