Home » Keywords: » hydronic heating

Items Tagged with 'hydronic heating'

ARTICLES

Hydronics Workshop | John Siegenthaler

Why accurate performance measurements are essential when evaluating an existing hydronic system for a heat pump.

Read More

The Glitch & The Fix: April 2025

Unexpected results: heat pump system at low outdoor temperatures

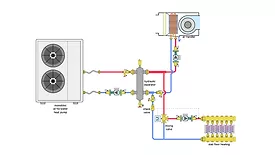

Consider the “dual temperature” heat pump system shown in figure 1

April 4, 2025

Renewable Heating Design | John Siegenthaler

Versatility in direct-to-load systems, part one

Going direct.

March 12, 2025

Heating Perceptions | Scott Secor

Old home needs entirely new heating system; is it worth it?

Exploded radiators

March 10, 2025

Hydronics Workshop | John Siegenthaler

Be prepared to advocate for hydronic-based heat pump systems

Different strokes.

March 9, 2025

Renewable Heating Design | John Siegenthaler

When one heat pump isn’t enough — part two

Simultaneous heating and cooling with multiple heat pumps.

February 12, 2025

Hydronics Workshop | John Siegenthaler

Heat pumps open possibilities for DWH and hydronic-based cooling

Expanding a concept — part two.

February 4, 2025

Heating Perceptions | Scott Secor

Low-pressure steam boiler piping gets much-needed replacement

71-year-old piping failure at an apartment complex resulted in many challenges.

January 8, 2025

Renewable Heating Design | John Siegenthaler

When one heat pump isn’t enough

Part one.

January 7, 2025

Duel-fuel solution offers best of both worlds

Hydronic electrification leverages residential solar.

January 7, 2025

Keep your content unclogged with our newsletters!

Stay in the know on the latest plumbing & piping industry trends.

JOIN TODAY!Copyright ©2026. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing