The Glitch & The Fix

One size doesn't fit all when it comes to piping sizes

All images courtesy of John Siegenthaler

The Glitch:

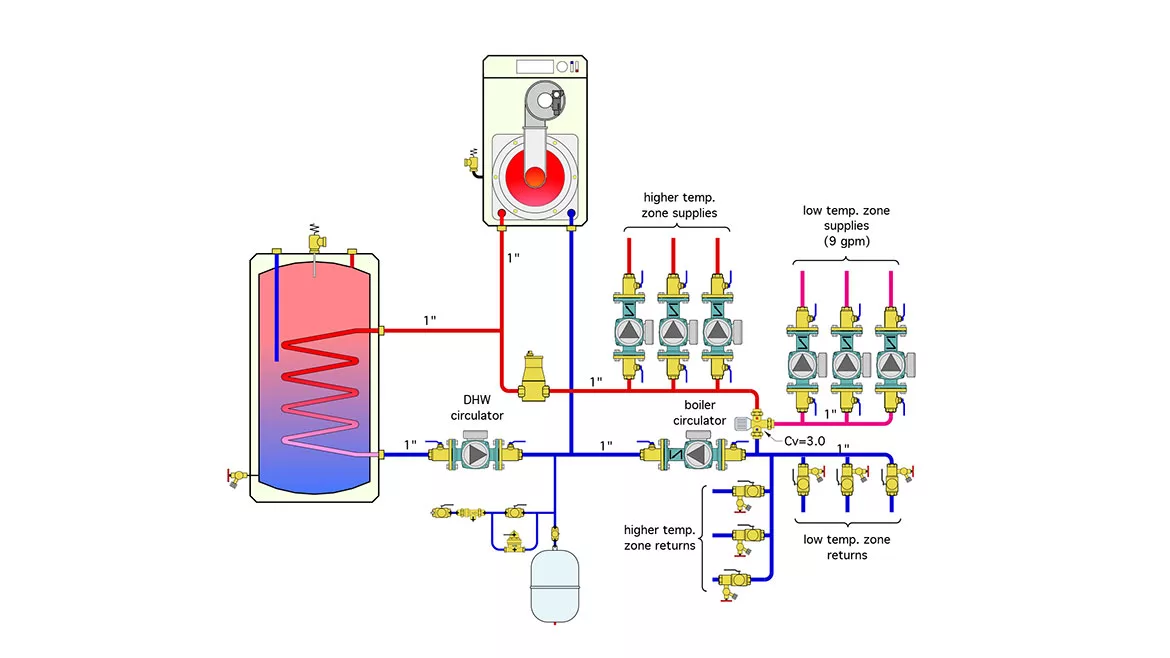

A project requires both medium and low-temperature radiant floor panels. The installer proposes the following system design. Since the mod/con boiler already has an internal outdoor reset controller, the installer chooses a standard 1-inch tempering valve to drop the water supply temperature to the lower temperature zones. The installer also decides that since the boiler supply and return connections are 1-inch, he can pipe the entire system with 1-inch tubing. Can you spot at least six design or installation details that are going to create problems?

FIGURE 1

The fixes

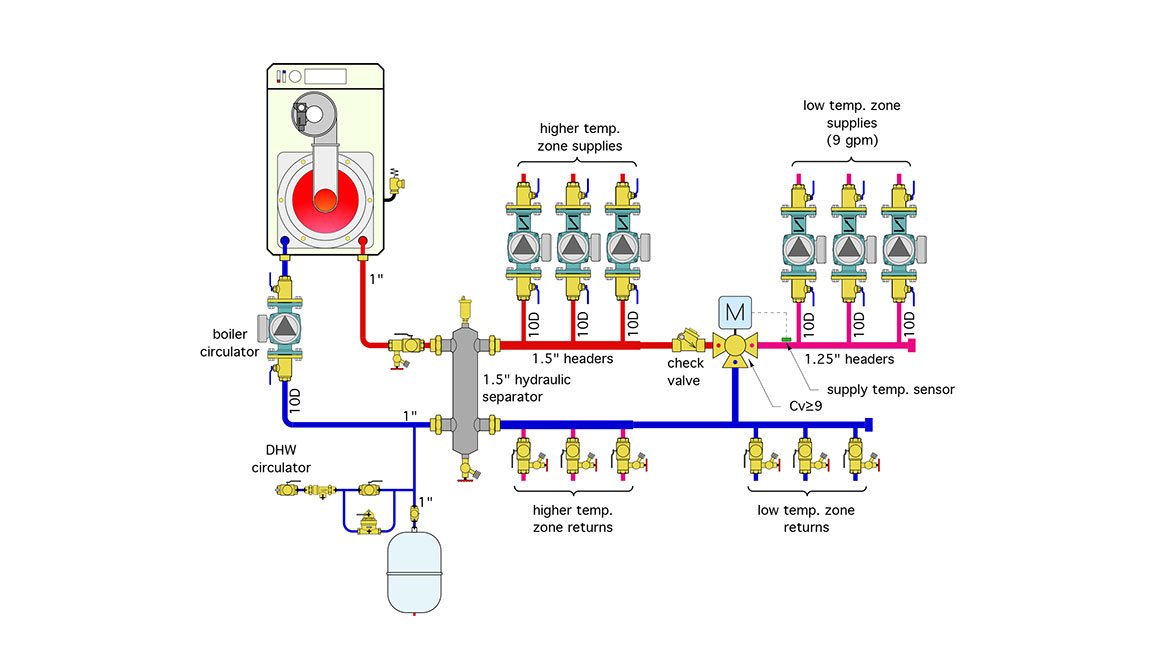

The header piping in the original design is the same size (1-inch) as the piping to individual zone circulators. This will create a high pressure drop when all zone circulators are operating, and that will lead to interference between the zone circulators. To avoid this, the header sizes in “The Fix” drawing (Figure 2) have been increased to 1 1/2-inch and 1 1/4-inch, as shown.

FIGURE 2

The boiler circulator needs to be hydraulically separated from the circulators in the distribution system. The individual zone circulator should also be reasonably hydraulically separated. This separation, as well as air and dirt removal, have been provided using the hydraulic separator and the upsized headers, as shown in Figure 2.

The 1-inch tempering valve with Cv=3.0 has been replaced with a properly sized 3-way rotary mixing valve with a much higher Cv (Cv of 9 or more) and hence lower pressure drop. A check valve is installed in the hot water supply to the 3-way mixing valve to prevent flow reversal when other zones are operating.

The purging valves on the return side of some of the zone circuits in Figure 1 were installed backward. The isolating ball within the purging valve should always be closer to the header than the drain port.

All zone circulators in Figure 1 appear to have very little distance between their inlet port and the header. This distance should be a minimum of 10 pipe diameters to reduce the level of turbulence entering the circulator.

The DHW circulator in the original drawing lacks a check valve. Without it, there will be reverse flow through the coil of the indirect water heater when the space heating portion of the system is operating.

The point of no pressure change in the original system is incorrectly located on the discharge side of the circulators. Figure 2 shows it tapped into the lower-temperature piping near the hydraulic separator.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!