The Glitch & The Fix: One size doesn't fit all

The Glitch:

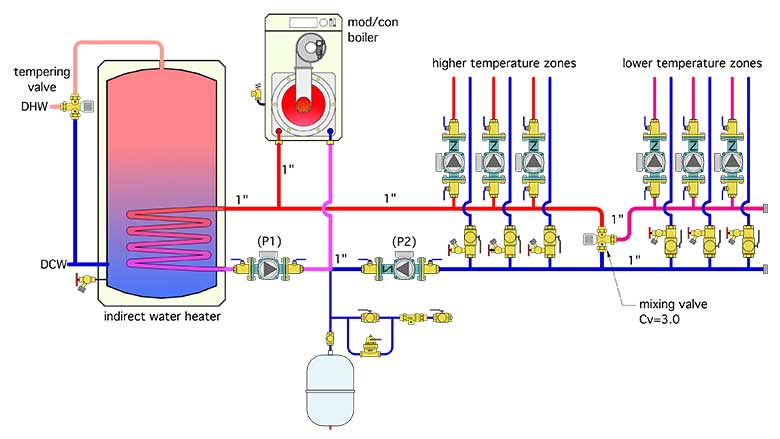

A project requires both medium temperature (140° F at design) and low temperature (105° F at design) radiant floor panels. The system will also supply domestic hot water using an indirect water heater. The installer proposes the system shown in Figure 1. Assume each zone circuit requires a flow rate of 4 gpm when operating. Since the mod/con boiler has 1-inch pipe connections, the installer decides to use a 1 inch domestic hot water tempering valve to lower the water supply temperature to the lower temperature zones. He also decides to pipe the entire system with 1-inch tubing.

Can you spot at least six design or installation details that are going to create problems?

[click image to enlarge]

[click image to enlarge]

The problems

- If the total design flow rate is 6x4 = 24 gpm, the 1-inch header piping is grossly undersized. Its use will likely create a high pressure drop when all zone circulators are operating. The undersized piping will also create more hydraulic interference between simultaneously operating circulators;

- The circulator labelled (P2) is in series with the zone circulators. The mod/con boiler requires a dedicated circulator that is hydraulically separated from the zone circulators;

- There is no central air separating device in the system;

- The purging valves are installed upside down;

- The expansion tank is very close to the outlets of circulators (P1) and (P2);

- The inlets of the zone circulators are shown very close to the header. This creates turbulence at the eye of the impellers, which could induce cavitation. There should be at least 12 pipe diameters of straight pipe on the inlets side of all circulators;

- The 1-inch tempering valve with Cv=3.0 is grossly undersized to supply 3 zone circulators at 4 gpm each. Pushing 12 gpm through a valve with a Cv of 3.0 would require about 16 psi. That’s much higher than any residential zone circulator can manage. A mixing valve with a Cv of approximately 12 would be the proper selection;

- The DHW circulator lacks a check valve. Without it, there will be some reverse flow through the coil of the indirect water heater when the space heating portion of the system is operating; and

- A mod/con boiler serving 6 zones is likely to experience short cycling when only one zone is on.

One fix

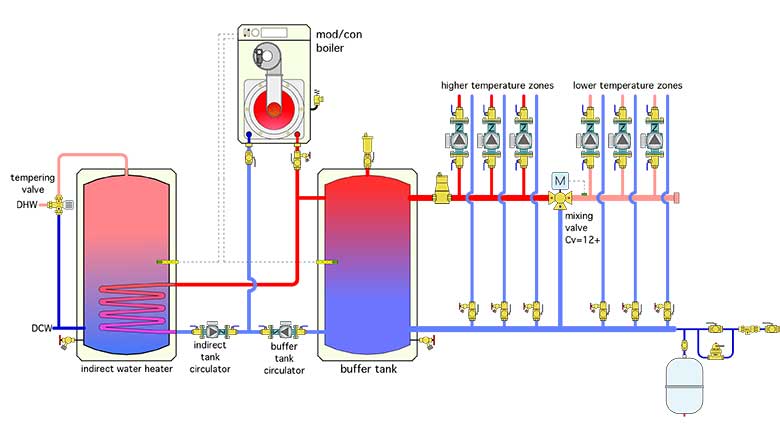

One way to correct the short-cycling issue is to install a buffer tank as shown in Figure 2.

[click image to enlarge]

[click image to enlarge]

The buffer tank temperature is regulated by the boiler’s internal controller. It could be based on a setpoint with differential, or on outdoor reset control. The latter would improve the boiler’s efficiency, and the logic for such controller is built into most modern mod/con boilers.

A higher flow capacity mixing valve is used to reduce the water temperature to the lower temperature zones.

Other details that were incorrect in Figure 1 have been corrected in Figure 2.

Another fix

Although the system in figure 2 will work, it does require two tanks, one for domestic water heating and another for buffer. Needless to say (but I’ll say it anyway…), tanks are getting pretty expensive these days, especially when you need two of them.

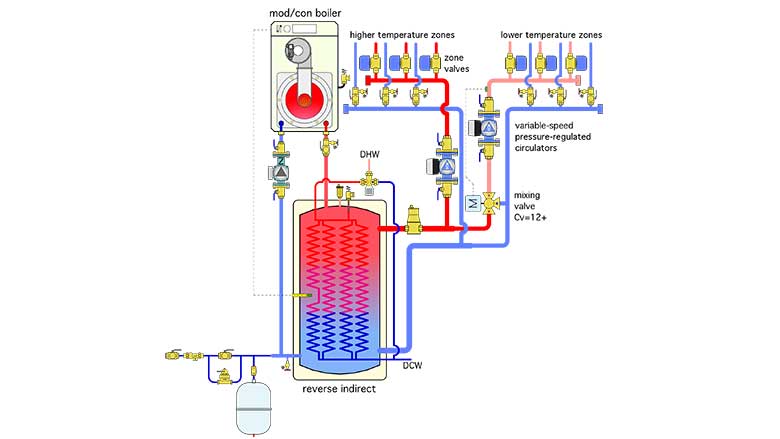

The system shown in Figure 3 uses a reverse indirect water heat to provide domestic hot water (through its internal coils) as well as buffer the space heating loads. This tank also provides hydraulic separation between the boiler circulator and the two load circulators.

[click image to enlarge]

[click image to enlarge]

The boiler would maintain the temperature within the tank at a temperature that:

- Is always high enough to provide the required DHW delivery temperature; and

- Is always high enough to supply the higher temperature radiant panels.

At design load that temperature would be 140° F (e.g., the stated design load supply temperature for the higher temperature panels). This is also likely to be hot enough to supply a typical DHW load.

Under partial load conditions the tank temperature could likely be reduced, but not lower than needed to produce the required DHW deliver temperature.

The load side of the system does away with 6 zone circulators, replacing them with 6 zone valves and two variable-speed pressure-regulated circulators.

This approach also requires less space in a mechanical area, and reduces standby heat loss since only one tank is holding heated water.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!