The Glitch: Primarily problematic

The Glitch:

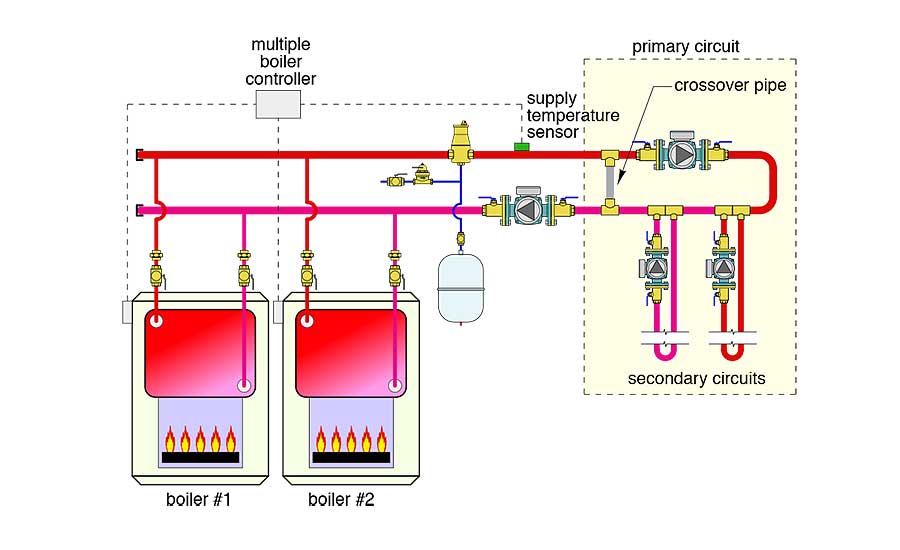

A multiple boiler system using sectional cast-iron boilers has been configured to supply two loads as shown below. A “crossover pipe” is installed in case the flow rate in the primary circuit is different from the flow through the boilers. The boilers are controlled by a multiple boiler controller that senses the water temperature leaving the boilers and upstream of the crossover. Each secondary circuit is connected to the primary circuit using closely spaced tees. There are several piping and control-related errors in this proposed design. Can you spot at least 5 of them?

The Fix:

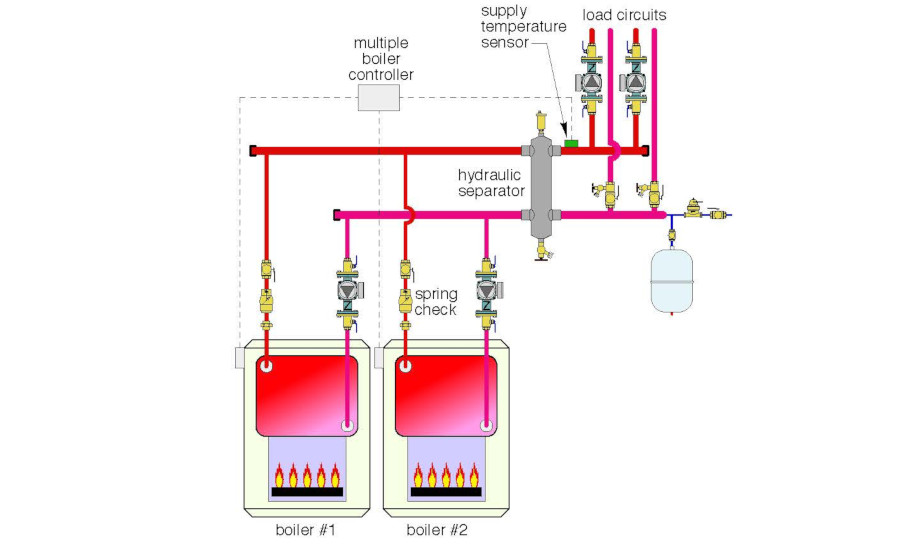

The solution shown does not require primary / secondary piping or closely spaced tees. It provides the same supply water temperature to each circuit. This eliminates the temperature drop from one secondary circuit to the next when a series primary loop is used. This arrangement also provides hydraulic separation of the load circulators based on a very low head loss through the hydraulic separator and “short/fat” headers. The hydraulic separator also provides air and dirt separation for the system, and thus eliminates the need for the air separator in the glitch drawing.

Here’s a summary of the other corrections:

-

Every boiler in a multiple boiler system should have its own circulator that only operates when that boiler is operating. The original schematic allows flow through all boilers regardless of which are firing. This results in needless heat loss as heated water is circulated through unfired boilers.

-

The unions and isolating ball valves that were installed with the intention of allowing each boiler to be isolated from the system and removed if necessary, are not installed so that this is possible. It’s a seemingly small detail, but one you should always check.

-

Always install the supply sensor for the boiler controller on the distribution system side of the hydraulic separation point. This is necessary because of mixing that could occur at the hydraulic separation point due to differences in the load flow rate versus the boiler flow rate. Installing the temperature sensor downstream of this mixing point ensures that the final mixed supply water temperature will be detected by the boiler controller. That’s the temperature that boiler control should be based on.

-

Every load circuit, whether it’s a secondary circuit as shown in the glitch drawing, or a parallel circuit, as shown in the fix drawing, should be equipped with a purging valve to allow efficient filling and flushing.

-

When using primary secondary circuits (as was the intent in the glitch drawing), the secondary circulators should always pump into their respective circuits. This allow the primary loop to serve as the pressure reference point, so that the pressure within the secondary circuit increases when the circulator is on.

-

In the glitch drawing the boiler circulator is pumping toward the point where the expansion tank connects to the system. There will be very little head loss through the sectional cast-iron boilers between this circulator and the the expansion tank connection point. This will cause a drop in pressure upstream of the boiler circulator when it operates. Air could be sucked into the system through vents if the pressure at their location within the system goes sub-atmospheric.

Please read here to view The Glitch & Fix: October 2018 in pdf form.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!