The Glitch & Fix: April 2018

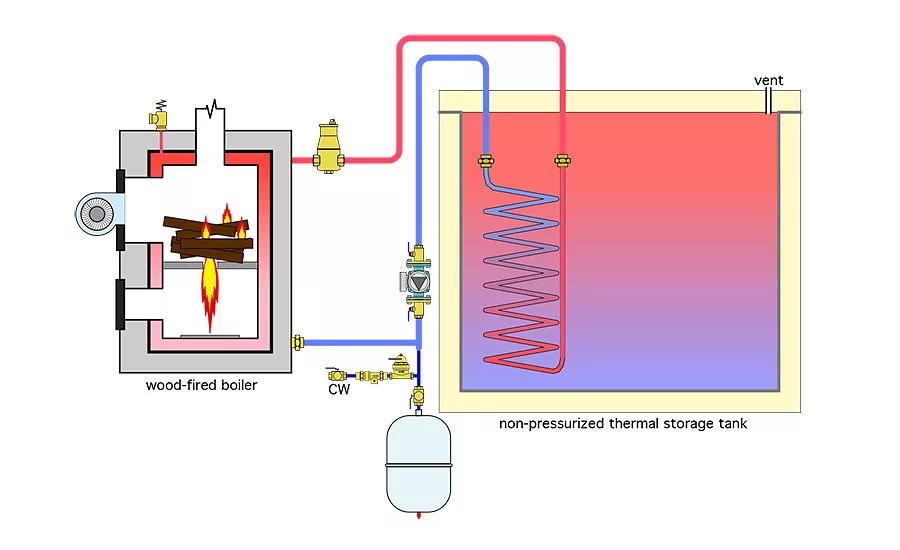

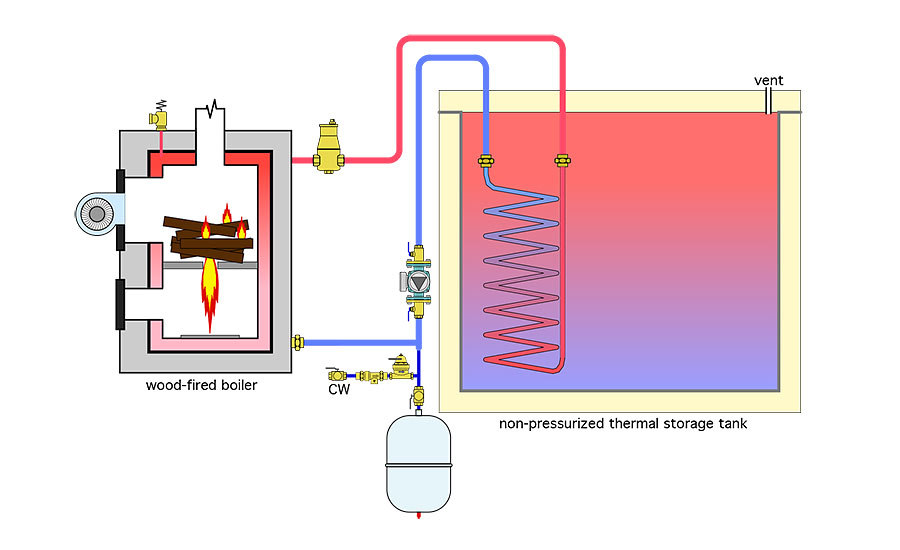

The Glitch:

A cordwood gasification boiler gets piped as shown. The boiler has a steel fire-tube heat exchanger. The tank is non-pressurized and has a vent hole through the upper lid. The heat extraction portion of the system is not shown. Can you identify at least five errors with this configuration?

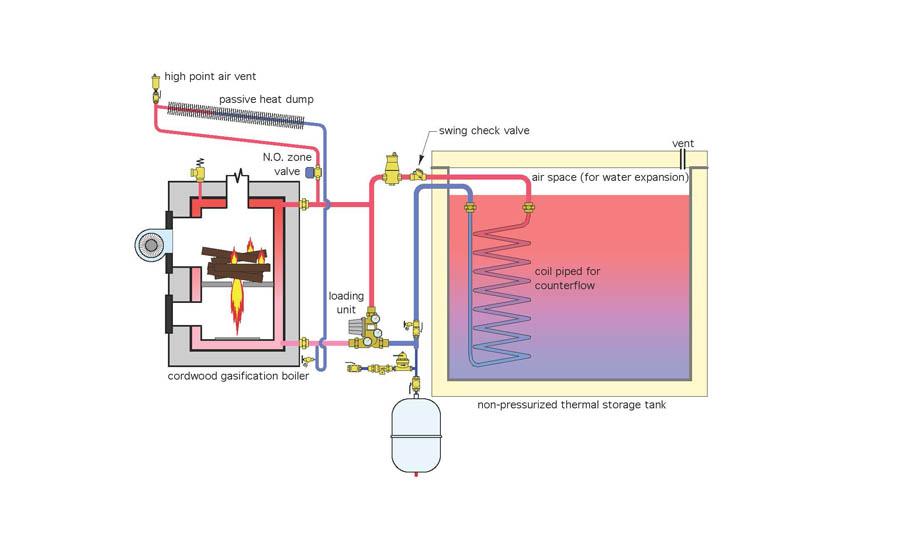

The Fix:

Here are the shortcomings of the original design:

-

All cordwood gasification boilers require a heat dump that can safely dissipate residual heat from the fire if a power outage occurs. A passive heat dump is common. It consists of an array of finned-tube installed above the boiler, supplied through a normally open zone valve. The latter opens when power is lost to allow thermosiphon flow between the boiler and finned-tube array.

-

All cordwood gasification boilers are designed to operate without sustained flue gas condensation. Some means of monitoring boiler inlet temperature, and reacting to keep that temperature above a minimum of about 140 ºF must be provided. In the fix drawing this is handled by a “loading unit”, which combines a thermostatic mixing valve with a circulator.

-

For best performance, all heat exchangers should be piped so that flow passes through or across them in opposite directions. This is called counterflow. As water in the tank is heated buoyancy forces cause it to rise as shown by the white arc in over the heat exchanger coil. Thus, for counterflow, the hottest water from the boiler should enter the top of the helical portion of the coil.

-

There should always be an air space between the water level in the tank and the underside of the cover. That space is intended to accommodate the increase in volume as the water is heated. As shown, the tank is completely filled with water. When the water is heated it will rise and likely leak out through the vent opening at the top.

-

In the original design the circulator is pumping toward the point where then expansion tank connects to the circuit. Circulators should always pump away from that point.

-

There is no check valve in the circuit to prevent reverse thermosiphon flow when the tank is hot and the boiler cools off. If allowed to occur, reverse thermosiphon flow will dissipate heat from the tank through the boiler and adjacent piping.

-

There is no union on the upper piping connection to the boiler, but there is on the inlet connection. Unions aren’t required, but it makes no sense to install one and not the other.

-

Although it may be possible to pass the piping leading to the heat exchanger through the top of the tank, this could complicate lid removal is necessary. It’s been to pass piping through the upper sidewall of the tank above the maximum water level.

These details have been resolved in the fix drawing below.

Please read here to view The Glitch & Fix: April 2018 in pdf form.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!