Large truck and car wash facility replaces aging boilers with multi-unit, wall-hung tankless water heating system

This case study covers a car wash business looking to upgrade its struggling boiler setup.

For over two decades, A-1 Truck & Car Wash relied on a conventional hot water system powered by two large, natural-draft, two-stage Laars boilers – each delivering two million BTUs. This lead-lag configuration meant one boiler operated to meet the demand, with the second activating only as needed.

The problem: If the primary boiler failed, only one unit remained to shoulder the full demand, leaving the facility vulnerable to service interruptions.

Given the operation’s high-volume usage, servicing 30 to 50 large commercial trucks daily along with a steady flow of car traffic, a reliable supply of hot water at the correct setpoint temperature was essential. Fully operational, the 10-bay facility requires up to 100 gallons of hot water per minute.

The dual boiler system’s age and comparatively low efficiency rating (around 60%) added to the sense of urgency. When the primary boiler began to fail, the owners recognized they needed a new, scalable, reliable and energy-efficient solution to support their demanding operations without the burden of a full boiler replacement.

As ownership looked to upgrade its aging boiler setup, A-1 was introduced to Noritz products by Barclay Sales, which enjoys a strong relationship with wholesaler Bartle & Gibson. The project came to Barclay through a direct call from the Bartle & Gibson hydronics team manager Justin Arneson.

Barclay’s solution?

“We proposed using five NCC199CDV Noritz commercial condensing tankless water heaters paired with a Noritz commercial controller,” says Barclay Outside Technical Sales Representative Josh Ferguson RSE, CPMR, who received the inquiry. Ferguson subsequently served as an advisor on the project, assisting the installer, Simpson Plumbing, a Bartle & Gibson customer also located in Lethbridge.

Solution

The Noritz commercial controller is programmed to manage lead-lag sequencing and load modulation. The high-efficiency unit adjusts its output in real time, delivering the required amount of hot water based on demand while also balancing system wear over time so that no one unit is used more than the other four.

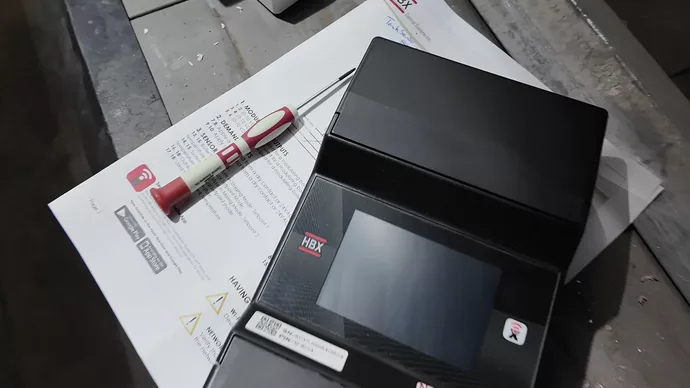

While upgrading to the Noritz commercial tankless water heaters, A-1 kept one boiler installed for now. A separate HBX controller, the CPU-0600, was installed to integrate and manage the legacy boiler as a secondary heat source, triggering it to supplement the tankless installation whenever needed to meet the load.

“The HBX is a staging controller that enables the tankless units to act as the primary heat source, maximizing both efficiency and reliability,” says Ferguson. “If, for any reason, the tankless system can’t keep up, such as when all 10 bays are operating at once, the HBX will activate the original boiler as a backup to boost output temporarily.”

Simpson Plumbing’s two-person installation crew, Technician Philippe Bergeron and Project Manager Colin LaRose, installed the wall-hung tankless units in a second-floor mechanical room. “It took us just two days to put in these units, including through-the-wall venting for each one,” says LaRose. An additional day was required for electrical work and system commissioning.

As Ferguson points out, that total of three days is still dramatically shorter than the seven to 12 days he estimates would be required for a traditional boiler installation, “even with twice the crew size,” he notes.

Measuring 27 inches (h) x 18.5 inches (w) x 12.8 inches (d), the compact NCC199CDV tankless units are about the size of a standard medicine cabinet and weigh approximately 81 pounds apiece — significantly smaller and lighter than a conventional boiler.

“The units were easily transported upstairs to the mechanical room,” says Ferguson. “So, the Simpson crew was able to avoid the need for a crane, which further lowered labor costs.”

Results

The upgraded system proved its reliability within its first few weeks of operation, routinely meeting A-1’s ongoing need for large amounts of hot water day after day without a hitch. With five independent tankless units, the multiple-unit setup also offers peace of mind through ease of maintenance: One or two water heaters can be quickly shut down for servicing without taking the entire system offline – an essential advantage for an ultra-busy business that can’t afford any downtime.

The installation experience with these tankless water heaters was especially gratifying to Simpson Plumbing, according to LaRose: “I have worked with installing the NCC199CDV tankless units in projects prior to the A-1 Truck and Carwash job, and I would recommend this product to anyone you who is interested in boosting installation speed and simplicity.”

According to Barclay's Ferguson, A-1’s tankless system cost half of a traditional boiler retrofit. The investment encompasses the five tankless units, the two controllers and pumps, but it does not include the crane services.

Energy-cost savings are expected to follow, with Noritz units delivering a Uniform Energy Factor of 0.96, compared to the outdated boiler’s 60% rating.

The A-1 ownership is already planning a second phase of domestic hot water improvements beyond the five tankless water heaters. The plan is to install five more tankless heaters and two Noritz Hybrid Hot Series units to replace the backup legacy boiler.

Hybrid Hot systems pair a high-efficiency commercial-grade tankless heater with a 120-gallon, cement-lined storage tank. Totaling 360 gallons of hot-water storage, the two Hybrid Hots will serve as the primary source of hot water, while the existing five, wall-mounted tankless units will activate as needed to meet excess demand.

In addition, the ownership has begun evaluating how tankless technology might be replicated at its other commercial properties. In short, the successful Phase 1 improvements at A-1 Truck & Car Wash stand as a testament to the potential of tankless technology for a wide variety of high-volume hot-water applications.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!