Ross Goldstein: Creating cooling and dehumidification using solar thermal or waste heat

Liquid desiccant systems provide multiple benefits.

Photo: AnVr /iStock / Getty Images Plus via Getty Images

There are multiple ways to dehumidify a space — mechanical, reheat and desiccant to name a few. The biggest issue has been that conventional air conditioning units are only 10% effective at removing humidity. Until now, standard de-humidification systems were expensive to purchase and install.

Using regenerative desiccant technology is less expensive than standard desiccant systems The technology is regenerative liquid desiccant systems. The firm who I have been speaking with since the beginning is AirGreen, from New Castle, Delaware.

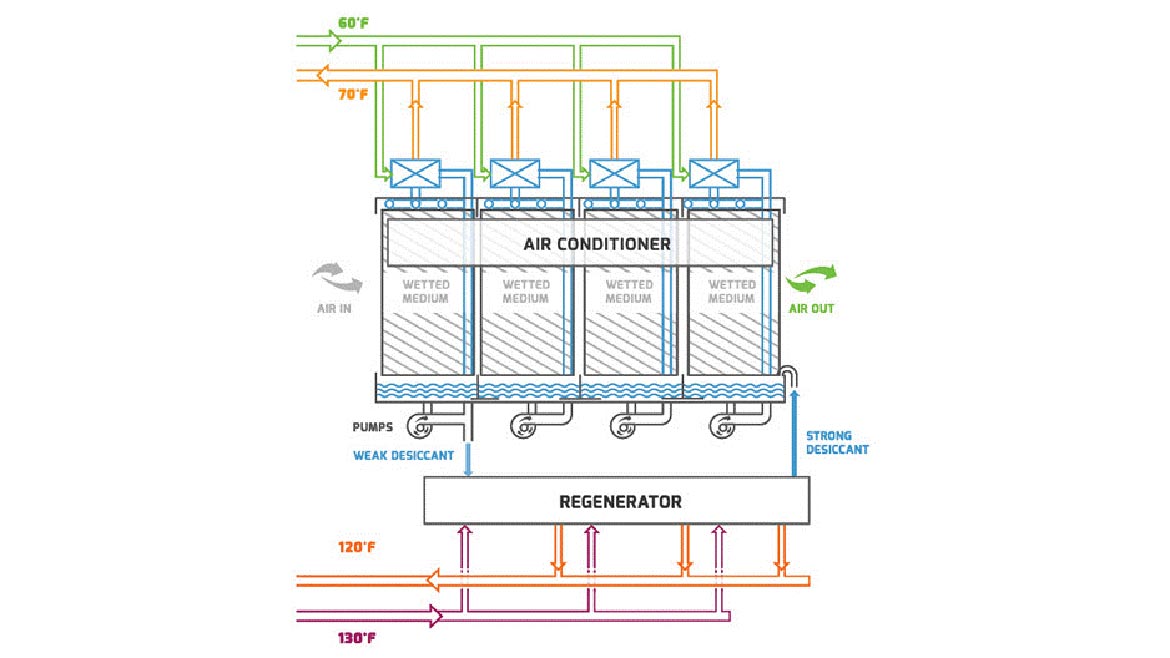

The reason the system can accomplish both precise humidity control and cooling is because it is composed of multiple modules. Their system is comprised of both a multi-stage air conditioning module that cools and dehumidifies, and a regeneration module designed to re-concentrate a proprietary desiccant solution. In the air conditioning module, the liquid desiccant solution is cooled using indirect contact with a chilled water source and circulated on a closed-loop basis throughout media cassettes. This media presents a cooling surface for the incoming air stream while also stripping the airstream of moisture (humidity). The chilled water source comes most commonly from a water-source heat pump or cogeneration equipment designed for such use.

When compared to mechanical systems that overcool and reheat to control humidity, regenerative liquid desiccant technology can save up to 60% in cooling season energy costs. Because comfort is enhanced by providing drier air, the actual A/C setpoint can be increased with no loss in comfort. Finally, this liquid desiccant cooling system also scrubs the air of pollutants, pathogens and microbes, improving air quality and reducing the chance of mold formation — which can occur frequently when moisture and humidity are not addressed.

When compared to mechanical systems that overcool and reheat to control humidity, regenerative liquid desiccant technology can save up to 60% in cooling season energy costs.

The benefits of a liquid desiccant system include:

- Reduced energy costs via simultaneous air cooling and dehumidification;

- Neutralization of airborne microorganisms and pathogens;

- Reduction or elimination of mold and bacteria;

- Improved ventilation via more energy-efficient treatment of outside air;

- Reduced refrigeration tonnage by eliminating costly sub cooling and reheat of process air; and

- Improved product quality.

FIGURE 1 [click image to enlarge]

FIGURE 1 [click image to enlarge]

This multi-stage liquid desiccant system that can manage latent heat ratios up to 100%. The products use both cold and hot water to provide sensible and latent cooling in summer and heating and humidification in winter. Enthalpy recovery from the exhaust airstream is approximately 85%. When used with a water-to-water heat pump, both the cold and hot side COPs are typically 5.0 or higher.

The second way to provide cooling and dehumidification is to use an absorption chiller, such as the one used at Steinway Piano Co. This application used 38 solar concentrated systems connected to a 99-ton chiller. The system was designed so that if dehumidification was not required, the steam would go to a heat indirect heat exchanger to provide heat for the factory.

Hydrogen burners

Greening the boiler systems. If a facility has an oil, natural gas or propane burner, you can retrofit it with a hydrogen-based burner. Very soon, these types of burners will be readily available in the market.

The Regenerative can use any form of hot water including solar thermal, waste heat, boilers and more.

I would like to thank AirGreen for assisting in the writing of this article.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!