A guide to rebates, including how to stack them

Rebates, without the headaches

When a contractor presents a net cost after incentives, the cost for the project becomes a lot more digestible.

In today’s construction environment, where material costs remain elevated and owners are scrutinizing every line item, rebates have taken on a much larger role than simply being a post-installation bonus. Manufacturer incentives, utility rebates and government programs are increasingly influencing how projects are specified, sold and approved. For contractors, understanding how to combine—or stack—those incentives can be the difference between a project that stalls at the proposal stage and one that moves forward.

Historically, rebates were treated as back-end savings: paperwork submitted after the job was complete, with the expectation that a check would arrive weeks or months later. While that’s still often the case administratively, the way rebates function in practice has changed. Today, contractors who understand incentive structures are using rebates as a front-end sales tool, helping customers see the net cost of a project rather than reacting to the sticker price alone.

At their core, rebates are designed to influence buying behavior. In marketing terms, a rebate is a partial refund offered after purchase to reduce net cost without changing the listed price. While the concept is most familiar in consumer retail, the same principle applies in the construction and mechanical trades, where rebates are used to encourage the adoption of specific products, technologies or efficiency levels.

Manufacturers rely on rebates to drive volume and brand loyalty, particularly where list pricing is tightly controlled. Instead of offering across-the-board discounts, manufacturers use rebates to reward contractors for choosing qualifying products, meeting volume thresholds or participating in preferred programs. As industry publications, such as Pro Builder, have noted, contractors who ignore available manufacturer rebates are often leaving meaningful dollars on the table; sometimes on products they were already planning to install!

Utility and government rebate programs operate with a similar goal, but on a broader scale. Programs administered by utilities or state energy offices are intended to accelerate adoption of high-efficiency and low-emission technologies, reduce peak demand, and support long-term energy planning. Federal initiatives, including those tied to the Inflation Reduction Act, are structured to work alongside state, local and utility incentives, allowing multiple rebates and tax credits to be applied to a single project when program rules are followed, according to guidance from organizations like Rocky Mountain Institute (RMI) and the U.S. Department of Energy.

This creates two major opportunities for contractors; first, properly stacked incentives can significantly improve project economics by lowering the customer’s out-of-pocket cost. Second, rebates can be brought into the sales conversation early, helping contractors address cost objections and position higher-efficiency or higher-performance systems as more attainable. Industry sales and rebate-management platforms have shown that customers are far more receptive to premium upgrades when proposals clearly show how incentives reduce the final price.

That said, rebate stacking is not a free-for-all. Each program has its own eligibility rules, documentation requirements and limitations on how incentives can be combined. Misunderstanding those details can delay payments, trigger clawbacks, or result in denied rebates altogether. Successfully using rebates—both as a compliance-safe financial strategy and a sales tool—requires coordination, clarity and a solid understanding of what is allowed.

With a little time and research, contractors can stack incentives without crossing compliance lines, and those same rebates can be used more effectively at the front end.

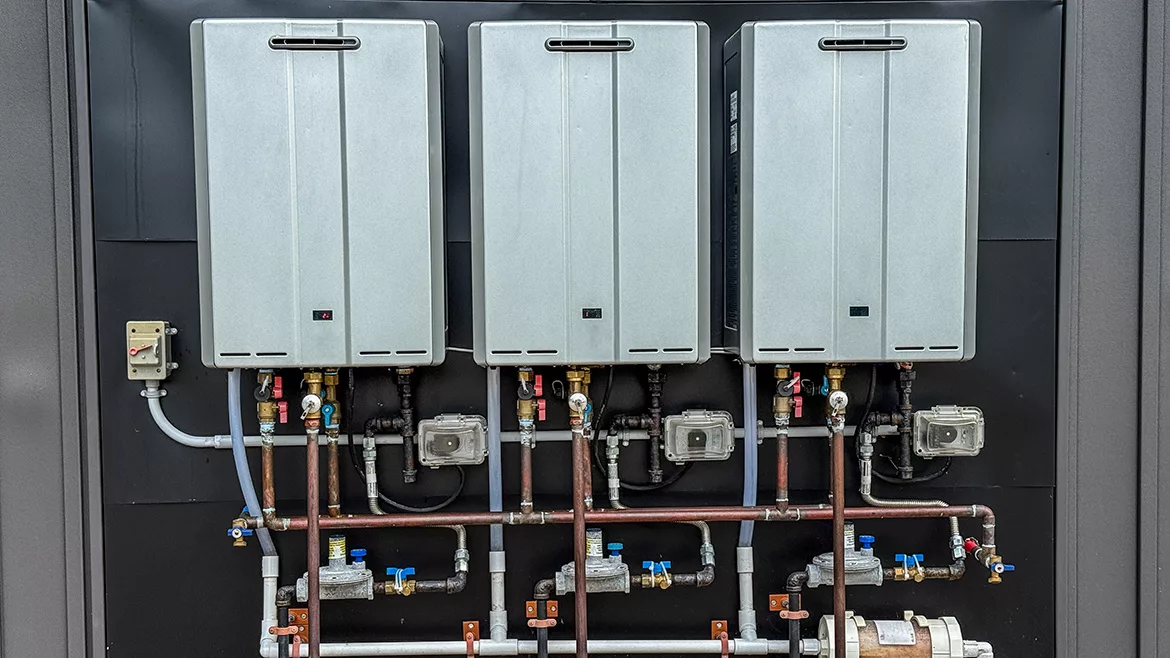

Presenting rebate amounts and net costs alongside energy savings over time can shift the conversation from "How much will it cost?" to "What’s this really worth?" Image source: alacatr / iStock / Getty Images Plus

Changing the sales narrative

Contractors who treat rebates as an afterthought are missing one of the most effective levers available in today’s sales environment. Rather than just seeing incentives as post-install savings, framing them at the proposal stage can help shift conversations from sticker shock to net value; a powerful tactic when customers wrestle with upfront cost objections.

Industry practitioners and rebate administrators emphasize that including incentive estimates in every quote is now the best practice. This concept’s effectiveness hinges on two key points:

- Perceived cost reduction drives decision making: Rebates function as a form of post-purchase discount that reduces perceived financial risk. Research into rebate strategies shows that rebates make a purchase more appealing by lowering the net cost customers anticipate after incentives, which in turn can accelerate decision-making in price-sensitive categories.

- Educated customers close faster: Contractors who equip customers with rebate information up front help demystify the incentive landscape, and reduce the "too good to be true" skepticism that often accompanies rebate discussions. Easy access to incentive tools and rebate lookup functionality — such as manufacturer or ENERGY STAR rebate finders — allows customers to see real, localized incentive values tied to specific products, giving them confidence that projected savings are legitimate.

Practical sales leaders in the trades echo this. While some might think that rebates are a hassle, including them in proposals is an excellent motivator for customers – especially those who are price-conscious. These days, many contractors can use dedicated software, including rebate estimation and processing tools, to ensure customers see and understand every incentive available to them.

However, it’s important to avoid simply slapping a rebate number on a proposal without context. Walk your customers through how incentives work and what they actually reduce on the customer’s bottom line. Whether it’s midstream incentives that reduce cost at the distributor level or delayed utility payouts, transparency builds trust — especially when rebate checks arrive after installation!

Real numbers, real impact

For many customers, the biggest barrier to upgrading to high-efficiency equipment or electrification measures isn’t a lack of interest: it’s upfront cost. That’s where rebates and federal incentives can move from an administrative afterthought to a front-line sales tool that helps close deals.

Under the federal Inflation Reduction Act (IRA), a suite of point-of-sale rebate programs offers significant incentives on qualifying energy-efficient upgrades. These rebates are designed to be claimed at the time of purchase or shortly after installation — meaning contractors can use them in sales proposals to illustrate real, tangible savings. For example:

- Heat pumps for space heating or cooling can qualify for rebates up to $8,000.

- Heat pump water heaters can be eligible for up to $1,750.

- Non-appliance upgrades such as panel upgrades ($4,000), wiring ($2,500), or insulation and air sealing ($1,600) are also included, with a maximum total rebate of $14,000 per household.

These incentives are structured to bridge the cost gap between standard replacements and high-efficiency or electrification upgrades. Important to note: actual rebate availability, timing and amounts depend on state implementation and household income eligibility.

Such numbers can be incredibly persuasive on the front lines. Picture a middle-income homeowner evaluating a switch from an aging gas furnace to a heat pump HVAC system that might retail for $10,000–$14,000 installed. A proposal that simply lists the gross price often triggers cost objections. But, when a contractor presents a net cost after incentives, for instance, showing a potential $8,000 federal rebate combined with qualifying utility rebates, the net outlay becomes a lot more digestible.

Plus, federal incentives extend beyond rebates into tax credits, which can further lower net cost. The Energy Efficient Home Improvement Tax Credit allows homeowners to claim a 30 percent credit on qualified upgrades up to a certain limit (e.g., up to roughly $2,000 on heat pumps and water heaters), and while this is claimed at tax time rather than at point of sale, it reinforces the total economic benefit of the project for the customer.

Contractors can illustrate this stack to customers in dollar terms:

- Start with the gross installed cost for a new heat pump system (e.g., $12,000).

- Subtract an $8,000 federal point-of-sale rebate under IRA rebate programs.

- Show additional utility rebates (e.g., $500–$1,000 typical for many utilities on heat pumps or heat pump water heaters).

- Then, explain how a 30% tax credit applies to the remaining qualified cost at tax filing (up to applicable limits).

The result — often thousands of dollars in reduced net cost — is a tangible financial motivator, rather than abstract future savings.

Tools like rebate calculators, utility incentive lookup resources and rebate management platforms make it easier than ever to estimate these savings accurately. Presenting rebate amounts and net costs alongside energy savings over time can shift the conversation from "How much will it cost?" to "What’s this really worth?"

By leading with incentives and detailing how federal and utility programs reduce out-of-pocket expenses, contractors can build proposals that speak directly to customer priorities: lowering costs today while improving performance and efficiency tomorrow.

With a little time and research, contractors can stack incentives without crossing compliance lines, and those same rebates can be used more effectively at the front end.

Common pitfalls and how to avoid them

Even the most sophisticated rebate strategy can be undone by compliance missteps, documentation errors or poorly drafted contracts. The rebates themselves don’t disappear, but incorrectly handled applications, misinterpretations of program rules, or vague contractual language can cost projects real money and expose contractors to liability. Here are the most common pitfalls contractors face and how to manage them.

A. Misunderstanding program rules

Rebate programs — whether utility, manufacturer or government — each have their own set of rules. Misunderstanding those rules can lead to ineligible claims, stacking the same category twice, or failing to meet specific criteria for a given program.

One common error is attempting to stack incentives that cannot legally be combined. Many rebate programs have explicit language about allowable combinations; failing to understand that language can result in denied incentives or compliance issues with program administrators.

Utility and energy incentive administrators can update eligible product lists, efficiency thresholds and stacking rules with little notice. These changes can affect whether a specific product, measure or rebate can be applied in combination with others. Keeping up with changing rules is one of the biggest challenges in rebate programs: rules can shift mid-year, incentive values reset, and certain measures require additional documentation or inspections.

How to avoid this:

- Study program documentation thoroughly before quoting incentives in sales proposals. Here’s where to start:

- DSIRE (Database of State Incentives for Renewables & Efficiency)

- Utility program websites

- U.S. Department of Energy (DOE) and ENERGY STAR

- Manufacturer rebate portals

- Confirm stacking eligibility with utility or program administrators early in the design process.

- Track changes to program rules throughout the project timeline, ensuring that what was eligible at proposal remains eligible at installation and claim submission.

B. Documentation errors leading to denials

Rebate denials often come from mistakes in documentation. A utility rebate denied because the installed lighting fixtures weren’t on an approved list, or because documentation lacked required technical specs, is an avoidable financial loss.

A common source of denied rebates is purchasing or submitting claims for products that don’t meet required specifications. Missed documentation can disqualify an otherwise eligible project: according to Incentive Rebate 360, "Utilities frequently require that products… meet specific standards to qualify for rebates. Purchasing products that do not meet these criteria can disqualify your application."

Other documentation pitfalls include: missing proof of purchase, incorrectly completed claim forms, missed submission deadlines or forgetting required pre-approval letters.

How to avoid this:

- Develop an internal documentation checklist that includes every form, certification and technical specification required by each program.

- Implement process controls such as a centralized "Rebate Bill of Materials (BOM)" and pre-approval stop gates; tools that lock in eligible products and ensure documentation is verified before installation.

- Verify product eligibility against official lists (like ENERGY STAR) before including specific models in your project scope.

Rebate stacking is not a free-for-all. Each program has its own eligibility rules, documentation requirements and limitations on how incentives can be combined.

C. Contract language considerations

Contracts are the frontline defense against disputes when incentive outcomes don’t go as planned. Vague or absent contract language around rebate responsibilities can expose contractors to risk, and in many jurisdictions, rebates may be treated as incidental to the installation unless clearly addressed in writing.

An analysis of contractor liability in rebate programs stresses this point: if rebate responsibility isn’t explicitly spelled out in the contract, courts and licensing boards might consider the contractor’s obligations complete once the installation is done — leaving the customer responsible for rebate outcomes. According to Rebate Beacon, a recommended clause looks like this:

"Contractor guarantees that all equipment meets [Program Name] requirements and will complete all necessary documentation for rebate approval. If rebate is denied due to contractor error, contractor will [refund difference/replace equipment/resubmit at no charge]."

Failing to include such a clause can leave a homeowner or business owner holding the bag — a result that is reputation-damaging for contractors.

How to avoid this:

- Define responsibilities clearly in the contract: who files rebates, what happens if the rebate is denied, how documentation timelines are handled, and what remedies are available for denial due to contractor error.

- Tie payment terms to rebate milestones if appropriate. For example, consider holding a final percentage of payment until rebate documentation is submitted or approved.

- Avoid verbal promises about rebate outcomes — every incentive and its conditions should be documented within the contract language or an attached rebate addendum.

Across all three risk categories — compliance rules, documentation and contracts — the overarching theme is clear: clarity, process and documentation matter. Whether you’re quoting incentives in sales conversations or filing final rebate claims, structured internal workflows, centralized checklists and well-crafted contract language can help manage expectations and – more importantly – protect your company.

The most successful contractors approach rebates with the same discipline they bring to system design and installation. They study program rules, verify product eligibility, document every step, and clearly define responsibilities in their contracts. Just as importantly, they bring rebates into the sales conversation early: helping customers focus on net cost and long-term value instead of sticker price alone.

Rebate stacking, when done correctly, rewards preparation. It favors contractors who coordinate across manufacturers, utilities and government programs, who stay current as rules evolve and who communicate incentives clearly and transparently. Those contractors are more likely to secure available dollars, and more likely to win projects, differentiate their proposals and build trust with customers.

In the end, incentives are doing exactly what they were designed to do: influence decisions. Contractors who understand that — and manage rebates as both a financial and sales strategy — can turn complexity into competitive advantage, and turn more proposals into project yeses.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!