Plumbing Essentials — Design Approaches, Codes and Everything in Between | Lowell Manalo and Robert Thompson

An approach to efficient MEP equipment room design

Considerations for an optimized mechanical room.

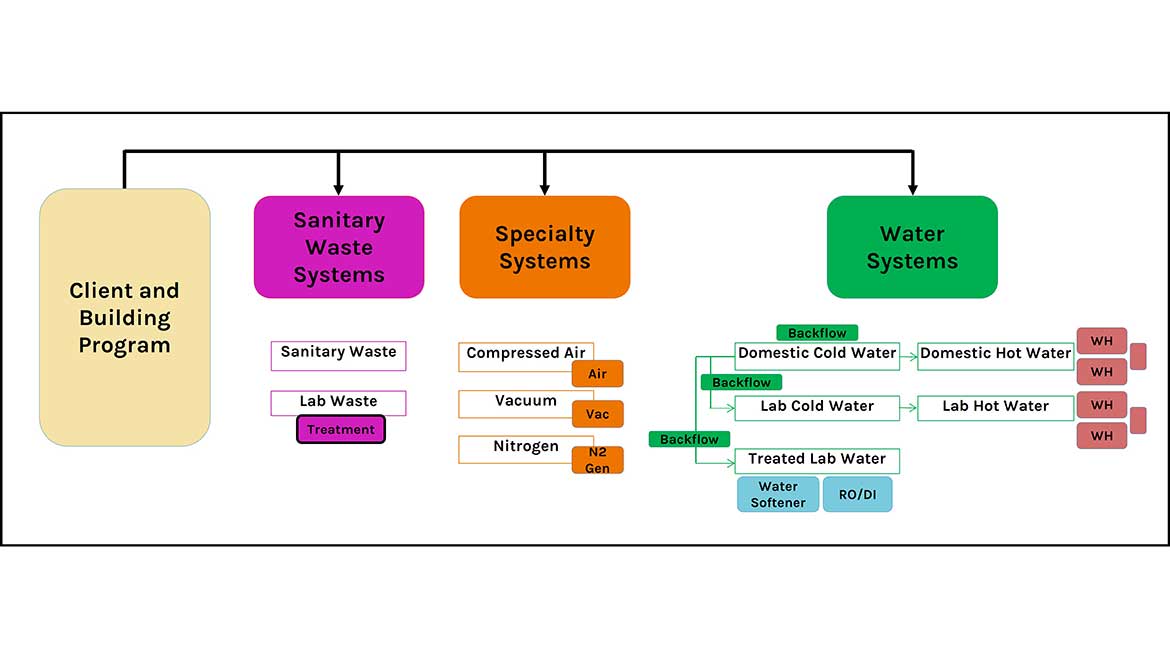

While architects work to efficiently organize program areas within a building, engineers must first envision the systems and their configurations before any meaningful equipment room sizing can begin. Initial discussions between the client and architect inform the purpose of the facility, its programs and other performance criteria. A site evaluation identifies potential resources or restrictions which form the foundation of functional building areas and orientation. These things taken together with input from others on the design team then becomes the basis of system diagrams and loads needed to support the facility.

Establishing system requirements in concept phase. Image courtesy of SmithGroup

The best equipment room designs involve active integration with the design team. While the room size is important, we also need to identify the desired proximity to building programs or systems and access requirements (are multiple access points needed?). Even with all this information known, it is rare to land on that optimized solution the first time. Needs from other programs may take priority over others, forcing compromises or reconsideration of initial thoughts (does the equipment require ground-level access, or are other locations viable with proximity to a service elevator or shaft?). While working to optimize spaces, architects may inadvertently limit or restrict access. Impacts such as these need to be communicated early on.

Often early equipment room planning focuses on the larger electrical and mechanical room components, but it is important not to overlook plumbing and fire protection needs. While mechanical equipment is larger, it typically has more flexibility in its placement. Some plumbing systems operate via gravity, and as such, are limited in how far they can be placed from core programs without becoming obstacles to other systems’ distribution. Other plumbing systems, such as compressed air and vacuum systems, can be quite noisy and generate vibration. A preferred plumbing equipment room location near building cores can be problematic if placed near sensitive equipment or program areas. Active discussions with architects and planners can identify potential concerns.

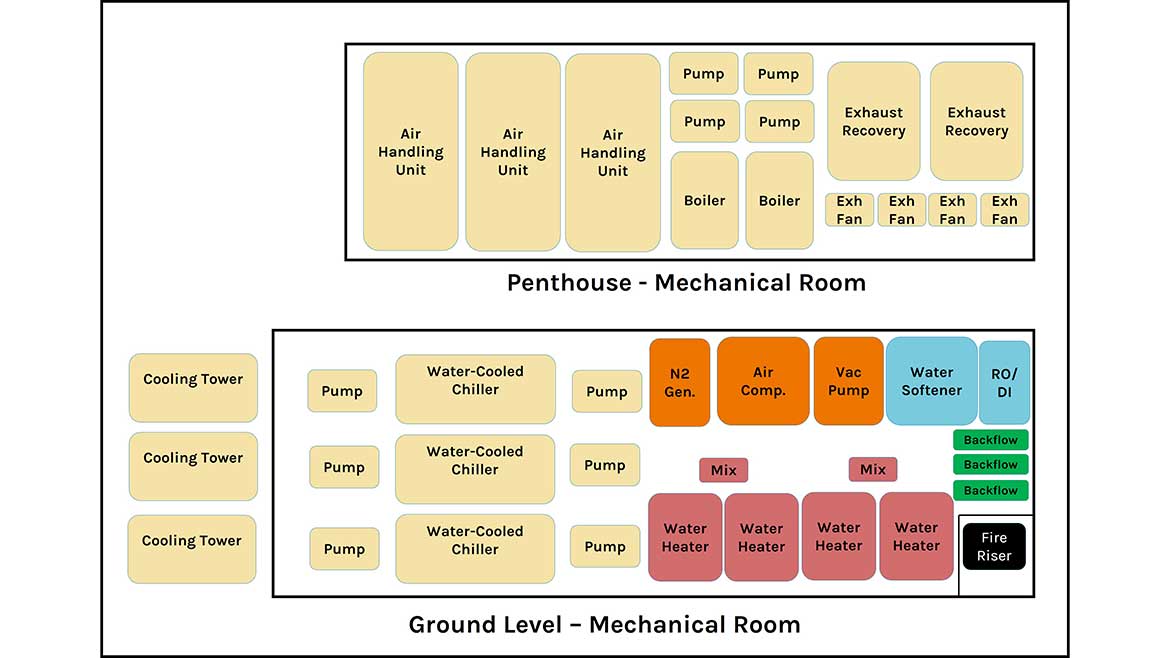

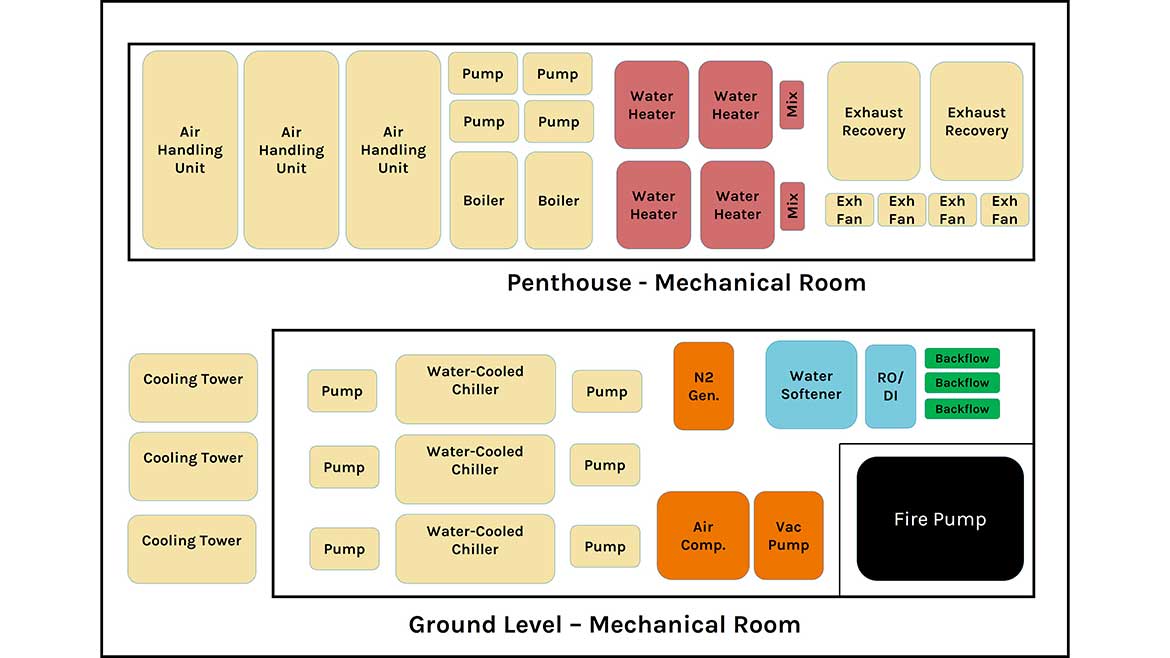

Electrical pathways into the building require a certain configuration, with site power feeding building transformers which are, in turn, delivered to the electrical service entrance. If emergency or standby power is required, then a generator and automatic transfer switches are needed. Similarly, fire riser rooms have specific criteria for their placement, so it is important not to overlook them in early planning. Will the building height and site pressure drive the project to require a fire pump? Does the building require a natural gas service, and if so what systems does it support? Ideally, natural gas distribution can be limited, with boilers and water heaters either in the same room or along the distribution pathway from the meter.

Ground level mechanical room with small fire riser room. Image courtesy of SmithGroup

Enlarged fire pump room with Penthouse water heaters. Image courtesy of SmithGroup

Once the equipment rooms with their relative size have been identified, the process of optimizing their layout can begin. The larger equipment and their access requirements often take precedence, though they must also be balanced together with their flow diagram. Failure to review the flow diagram prior to equipment layout may force inefficiencies in system distribution making systems difficult to understand, install and operate. The best pathway for success generates high-level system sketches to test different configurations. These sketches can be generated quickly off the system diagrams and deficiencies identified. As the concepts begin to settle out, more detailed design can be done to validate results.

If the design is unable to support core building systems within the building envelope, another strategy migrates systems to packaged enclosures within an equipment yard. A packaged central plant, for example, can move all or a portion of the central plant out of the building, freeing up space for others. These systems are prefabricated offsite and shipped in containers. Once on site, these containers are joined together for form the central plant. While these may result in higher equipment costs, these systems can dramatically reduce field labor and construction time. As they are independent of the building configuration over time likely have minimal impact to the plant design and reduce the potential for revisions in the future. While often used for mechanical systems, larger plumbing systems can take advantage of this design approach.

Packaged Central Plant. Image courtesy of SmithGroup

Regardless of whether the equipment room is located in the building or on the site, there is a systematic approach to optimizing its design. The following framework identifies the mechanisms by which equipment rooms can be optimized:

- Define programs and identify unknowns. Integration and active participation with the design team and client goes a long way in identifying the needs and potential configuration of systems. System assumptions during this period can be vetted with the client and architect to provide a clear direction forward to understand what the building needs.

- Identify landmarks and required proximities. While we tend to focus on our systems, it is important to listen and understand the needs of other team members. They similarly have limitations on their programs, so understanding those will inform where best to locate certain program elements. Consistent conversations with the architect and design team reinforces the relative placement of these elements and how these can support the needs of the client for this facility.

- Start with larger elements and work down to smaller systems. Keep in mind that beyond normal maintenance, equipment will need to be replaced over the life of the building. An optimized solution does not landlock these elements and looks for ways to limit disruption and streamline operation. If a specific equipment type overly limits access, consider alternate approaches that provide the same functionality while maintaining access.

- Don’t overlook the supporting infrastructure. Mechanical equipment rooms often have supporting plumbing, electrical and control systems. An optimized solution with no space for electrical and control panels, transformers, backflow preventors and other will become cluttered. A comprehensive vision for equipment rooms brings together input from all of these disciplines to understand all of the components needed.

- Iteration is an essential element of optimized design. High-level sketches are a good way to begin to visualize the equipment room layout and access requirements. When these are then shared with other team members, the necessary infrastructure to support these programs becomes understood. That taken together with their service and access requirements may force additional iterations of the equipment room design, but in the end, generates a more comprehensive solution.

The best pathway for success generates high-level system sketches to test different configurations. These sketches can be generated quickly off the system diagrams and deficiencies identified. As the concepts begin to settle out, more detailed design can be done to validate results.

The best equipment room designs bring together input from multiple parties in the context of the building program to provide an informed, all-encompassing solution to the building design. As the building evolves over the course of its design, it is important to periodically revisit the design to ensure that the needs or sizing has not changed. Early engagement and consistent dialog with the design team provides the highest opportunity for success. Become an advocate for an optimized equipment room solution in harmony with the building program and use, and the facility engineer will become an advocate for you on their next job.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!