The Glitch + The Fix: Pellet particulars

The Glitch:

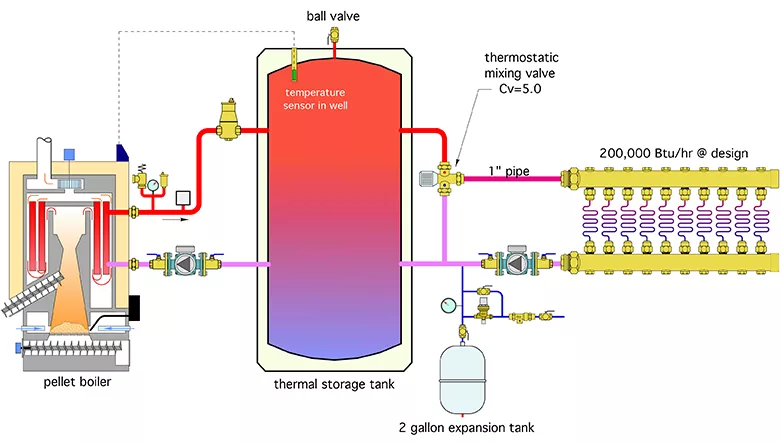

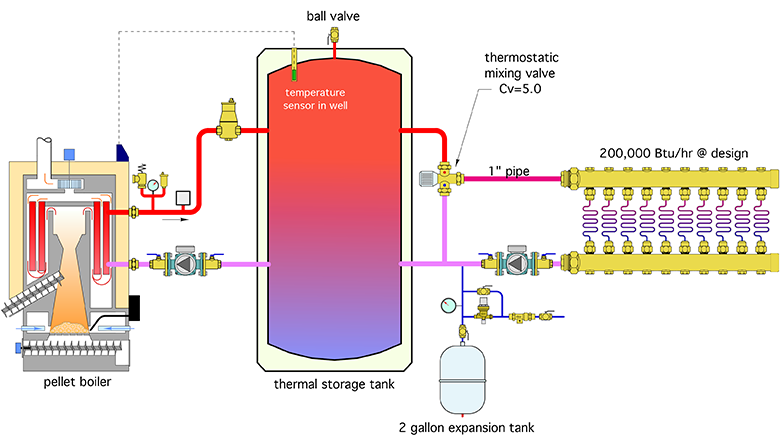

Because the price of fuel oil has increased dramatically over the last several months, an installer with lots of experience in installing conventional oil-fired boilers is asked to install a pellet-fired boiler. The boiler will supply a low-temperature floor heating system with a design output of 200,000 Btu/r. The installer understands that pellet boilers need thermal storage tanks, but assumes that many of the other installation details will be the same as for the oil-fired systems he’s worked with. The system he installs is shown in Figure 1. Can you look it over and diagnose what some of the problems might be? Can you propose a better design that would eliminate these problems?

FIGURE 1 [click image to enlarge]

What’s wrong?

- Like any “conventional” boiler, pellet boilers must be protected against sustained flue gas condensation. The high thermal mass of the storage tank, as well as the presence of a low-temperature distribution system make this critically important. The system in Figure 1 has no provision for this.

- Any thermal storage tank that has an attached vertical piping loop will attempt to set up a reverse thermosiphon flow when the boiler is off and there’s warm water in the tank. This can drain a significant amount of heat from the tank and must be prevented. A swing check valve will provide the solution.

- Although there is a ball valve present at the top of the tank, it can only vent air when someone operates it. A float-type air vent is a better choice for this application.

- The distribution side of the system has several issues.

- A mixing valve with a low Cv rating relative to the flow rate it is expected to handle. A 200,000 Btu/h load expected to operate with a 20° F temperature drop will require a 20 gpm flow rate. The mixing valve should have a Cv value close to this flow requirement.

- 1-inch size copper tubing should not be operating above a nominal 10 gpm. A flow rate of 20 gpm will require a minimum tube size of 1.5 inches.

- A 2-gallon expansion tank is way too small for a system with a thermal storage tank. A guideline for biomass heating systems is that the expansion tank volume should be roughly 10% of the thermal storage tank volume. The expansion tank is also incorrectly placed relative to the distribution circulator.

A couple of other observations are in order before moving to the fix.

The piping connections on the side of the thermal storage tank are quite a distance from the top and bottom of the tank. The hottest water will be at the top of the tank. The upper side outlet pipe from the tank, as shown in Figure 1, will leave the hottest water “stranded” in the top of the tank. Likewise, the lower two side connections will leave the coolest water stranded at the bottom of the tank. The tank will provide buffering, but the full volume of the tank is not being “exercised” in an optimal manner.

A single temperature sensor at the top of the tank, along with a setpoint and differential in not the optimal way to operate a pellet boiler. A better scenario is to turn on the pellet boiler when an upper tank sensor drops to some minimum value, and keep the boiler running until a lower tank temperature sensor reaches some relatively high temperature. This helps to “stack” more heat into the tank during each boiler operating cycle. It also lengthens the boiler on-cycles to improve efficiency and decrease particulate emissions.

The Fix:

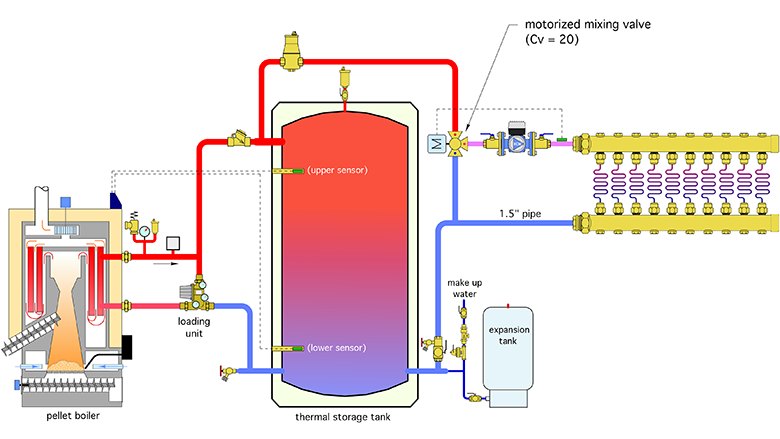

Figure 2 shows a design that addresses and corrects for the issues listed above.

FIGURE 2 [click image to enlarge]

The loading center combines a circulator and thermostatic mixing valve. The latter keeps the return flow to the pellet boiler above dewpoint whenever possible.

A swing check valve has been added at the upper side inlet of the tank to prevent reverse thermosiphon flow through boiler when it’s off.

A motorized mixing valve with a Cv of 20 provides minimal pressure drop and accurate regulation of supply water temperature. It could be operated in either setpoint or outdoor reset mode. The latter is preferred since it allows the tank to drop to lower temperatures during mild weather, which increases subsequent on-cycle time of the pellet boiler.

The thermal storage tank is piped in a “3-pipe” configuration which allows the hottest water from the boiler to flow directly to the load when both the load and boiler are operating at the same time. The side connections on the tank are much closer to the top and bottom of the tank.

Upper and lower temperature sensors are used to control the firing of the pellet boiler.

A float-type air vent and service valve are added to the top of the tank.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!