Top 5 pump myths debunked

Uncovering common misconceptions around pump system design, setup and maintenance.

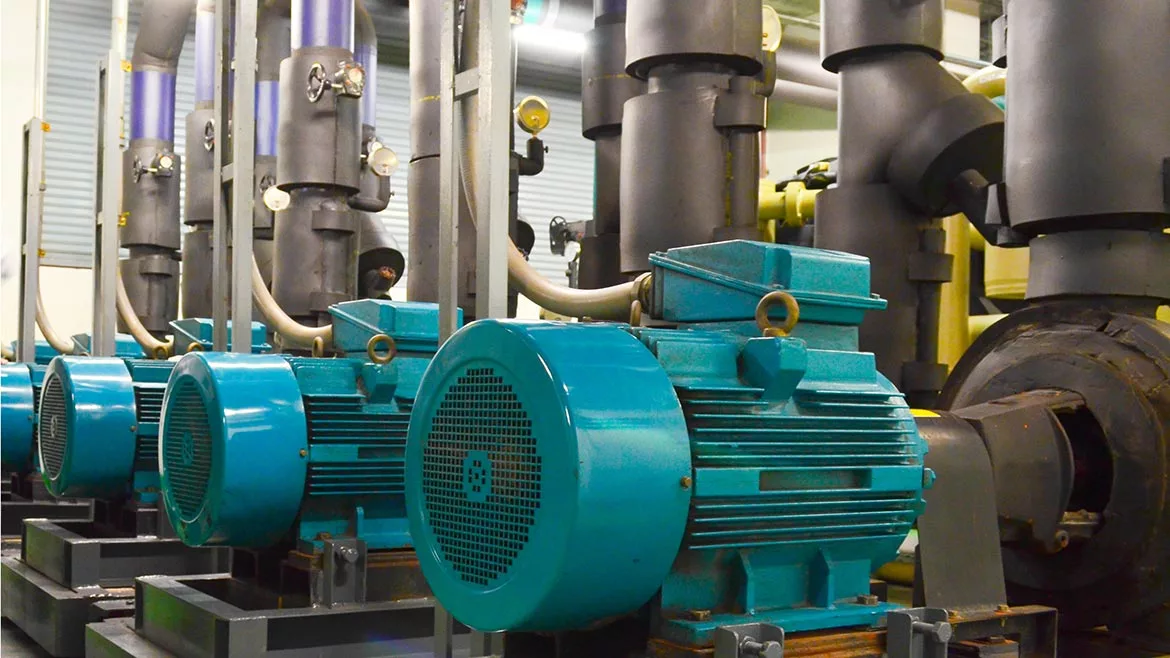

primeimages / iStock / Getty Images Plus via Getty Images.

Think you know pump systems? Think again. From misidentifying the major culprits of ownership costs to taking the wrong approach in implementing variable speed drives, misconceptions around pumps create missed opportunities for greater efficiency and cost savings.

With pumps typically accounting for 40% of the energy use in industrial fluid systems, facilities cannot afford misunderstandings around the technology and its requirements. Whether for food and beverage production, wastewater disposal or anything in between, designing your fluid system with an awareness of the following fallacies can make the critical difference in operational success.

Myth: Installation costs are the highest costs associated with pump systems

Truth: It is often assumed that initial purchase and installation costs are the largest aspect of a pump system’s complete lifecycle cost. In reality, energy and maintenance are responsible for the lion’s share of system expenses. A typical pump system, for example, often boasts a lengthy lifespan of more than 20 years. Throughout this period of ownership, it is likely that 65% or more of costs will go to energy and maintenance, while the original purchase and install will make up less than 20% of costs. Choosing to skimp on the purchase and install can result in an even greater disparity in these percentages. Considering this ratio, it is important to understand total lifecycle cost and how purchasing the most efficient pump that is properly selected for the system will cut costs over time versus getting hung up on the initial price tag.

Myth: Pumps are often the source of operational inefficiency

Truth: As with many technologies, efficiencies — and a lack thereof — stem not only from equipment design but also from operating methods. Inherently, pumps offer relatively high efficiencies, however, their operational efficiency is tied to system design and operation. The operational requirements that draw energy, such as flow rate and pressure, are requirements of the system. The pump is the vehicle that delivers that system, so the system’s operational efficiency is directly tied to the pump selection and control.

What does this mean? System design should precede pump selection and include careful considerations around how the setup uses energy, identifying ideal pump size and flow rates. Understanding what level of pressure — or head — the specific system requires, and how it will vary over time, will guide optimal pump selection and control. Once these system requirements have been considered and proper pump selection has occurred, the Hydraulic Institute’s Energy Rating (ER) Program provides a resource to select the most efficient pumps, comparing energy consumption rates for pumps and systems in the marketplace and advising on potential power savings from system upgrades and changes. Using such resources, along with a system-focused approach, will yield the greatest improvements in energy and maintenance efficiencies.

Myth: The technology used for pump systems is dated and unsophisticated

Truth: Today’s pumps are not your grandfather’s pumps. Technology has advanced to make pumps, and their interaction with the system, increasingly agile and intelligent. The introduction of smart pumps creates an adaptive system that knows the pump’s performance parameters, analyzes activity and can adjust pump operations in response to demand. Utilizing these learnings and adjusting the control can minimize downtime and increase efficiency (i.e. automatically changing control pressure setting based on a building’s actual heating or cooling demand).

Myth: Pumps are typically unnecessarily oversized

Truth: If and when pumps are “oversized,” meaning a safety factor is built in, it is to account for uncertainty in flow and pressure requirements, and sometimes future demands. It is important to consider this uncertainty because having a pump that is undersized for the demand will result in poor utility. In these cases, close management at commissioning can ensure that unnecessary power consumption is not occurring.

To limit the effect of an oversized pump, implement proper commissioning when the pump is installed and determine if the system can be balanced to limit flow rates, if a smaller impeller will reduce power consumption or if a control setting can be adjusted and still meet the system requirements. In systems that have variable conditions, it is likely adventitious to purchase a pump that includes a variable frequency drive, which can also help with oversizing by reducing the maximum operating speed to meeting the system’s actual requirements.

Myth: Variable speed drives always increase pump efficiency

Truth: When variable conditions exist, we can think of throttling the pump flow rate with a control valve akin to adjusting speed in our car with the brake, but not taking our foot off the accelerator. There is no question that variable speed pumping can boost system efficiency, but a common misconception is that simply adding a variable frequency drive is enough to improve system efficiency. In truth, there are a few more boxes to check when implementing the functionality. Does the system require variable operation? Does the system contain instrumentation to measure the system variable (i.e. pressure, flow, power, temperature, etc.) and feedback so that speed can be adjusted to meet a set point for this variable? Adding a variable speed drive to a pump without these considerations will not result in energy savings. Instead, approach this technology with a sense of how it will fall into your complete system and plans for extracting the right information.

With these misconceptions in mind, facility designers and managers, plant engineers and other pump system professionals can lean on industry authorities like the Hydraulic Institute for the latest guidance in pump selection, optimization and critical standards for operational efficiency. As the industry continues to evolve and adapt to heightened production demands and changing regulations, having a keen understanding of pump technology will foster a more cost-effective, responsible operation.

Discover more pump-related resources at pumps.org.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!