The Boiler Room

Ray Wohlfarth: Installing a trouble-free condensing boiler

A high-efficiency boiler replacement requires additional planning.

On the older hydronic systems, replacing the existing boiler with a new one was pretty straightforward. The installer connected the new boiler to the existing flue, piping and electric. The newer high-efficiency boilers are much different and require some additional planning.

Read the manual

The installation and operation manual is required reading when installing a new boiler. I realize they are long and somewhat boring, but hidden inside the instructions are tips that could mean the difference between a properly working system and one that isn’t. For example, you may discover the manufacturer does not want softened water for the boiler, and the existing system has a working softener connected. That is something you want to know before installing the new boiler.

How’s the power?

Many new boilers use circuit boards that control the combustion, monitor the operation and inform you of any fault. These controls are both a blessing and a curse. While they can help diagnose the fault, they can also be the cause of a failure. The newer microprocessor controls are more sensitive to electrical voltage irregularities than the traditional mechanical controls.

Another task is to check the wiring connections inside the boiler. A loose wiring connection could cause intermittent failures. Verify the wiring connections are snug. When checking the connections, confirm enough strands of wire under the terminal screw. We had sporadic issues on a newer boiler and discovered the control installer only had two strands of wire under each screw. We had to re-strip the wire and insert it under the terminal connection. Once done, the intermittent failures stopped.

What’s in the pipes?

Most new boilers and circulators have thinner internal passages compared to their predecessors. As a result, the rust and dirt inside the old pipes can plug the boiler or circulator. A pump manufacturer told me the leading cause of in warranty failures was from dirt clogging the pump. The installer should thoroughly flush the hydronic system prior to installing the boilers to avoid future problems. This flushing is critical to rid the system of older water treatment chemicals, stop leak compounds or old glycol which may not be compatible with the new boilers.

Who is in control?

The new boiler controls may manage the boiler firing rate, air to fuel ratio, firing sequence, water temperature, circulator operation and warm weather shutdown. We see a trend in the industry that the building control system is used to change the burner firing rate. The signal from the building control system may interfere with the boiler control system and cause nuisance shutdowns. I prefer having the boiler controls manage the operation of the boiler as the manufacturer knows how to properly operate their boiler. The building automation system should be used to enable or disable the heat in my opinion.

I prefer having the boiler controls manage the operation of the boiler as the manufacturer knows how to properly operate their boiler.

Venting the boilers

The non-condensing replacement boilers usually connected to the existing flue as they were both Category I appliances. The new condensing boilers are likely a different venting category and cannot reuse the existing flue. Consult the manual to see what is recommended. When venting through the sidewall, check the local codes as the flue gases may short circuit and be drawn back into the building if there are windows or air inlets nearby.

Water treatment

Water treatment is suggested for all boilers and crucial for condensing boilers. Consult the water treatment expert during the planning phase to see if additional water treatment components are needed. Inform the water treatment representative of the heat exchanger composition. For example, is it stainless steel or aluminum? The water treatment is different for each.

A water softener was often used with the older boilers to reduce the scale formation on the waterside of the boiler. Many new boiler manufacturers do not want softened water for the boiler as it could cause internal corrosion.

The new boiler’s glycol requirements may be different from the previous boiler. Consult the boiler installation manual for the type of glycol needed. Remember, glycol slightly reduces the boiler’s efficiency and circulator capacity, so factor that into the sizing calculations.

Remember the condensate neutralizer

Condensing boilers get the best efficiency by lowering the flue gas temperature below the dew point temperature, absorbing the latent heat from the gases. When the flue gases condense, acid forms, which could damage the drainpipes and fittings. To negate the effects of the acid, a condensate neutralizer should be installed. This device raises the pH of the condensate to be less acidic. Most municipalities require a condensate neutralizer on condensing boilers.

Condition of Combustion air

The condition of the combustion air for the boiler is critical for the long life of the new boiler. Contaminated combustion air could destroy the boiler and void the warranty. Verify the combustion air source can provide clean air. Avoid drawing combustion air from areas that contain chlorine, calcium chloride, refrigerant or excessive dirt and dust. We sold boilers to a local university, and they were doing construction outside the building. The dirt from the construction site was mixed into the combustion air and caused the boiler to trip regularly. The fireside of the boiler had to be cleaned because it filled with dirt.

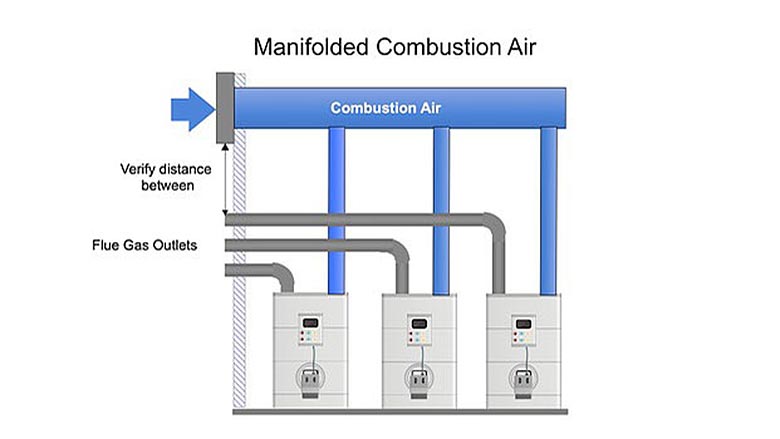

A common complaint we hear from building owners is the number of holes in the side of the wall when using multiple condensing boilers. Each boiler needs a hole for combustion air and another for flue gas discharge. One way to limit the number of holes in the wall is to manifold the combustion air together. I size the combustion air duct using one inch of free area for each 2,000 Btu/h of boiler input. For example, if we have three boilers, each rated for 500,000, we would have a total input of 1,500,000 Btu/h. The cross-sectional area of the combustion air duct would be 750 square inches.

Spare parts

When ordering the boiler, purchasing some spare parts is an excellent way to keep the customer happy, especially if there is only one boiler. I consult the manufacturer’s manual for their suggested spare parts. At a minimum, there should be a replacement flame rod and igniter, the two most common consumable items.

Keeping it problem-free

Keeping the boiler operating efficiently requires regular maintenance. One of the differences between a condensing and a non-condensing boiler is the extra maintenance required for a condensing boiler. The boiler fireside should be opened, cleaned and inspected each year. The heat exchanger can get plugged from the dirt in the combustion air and affect the efficiency and operation of the boiler.

caifas/iStock / Getty Images Plus via Getty Images

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!