Ray Wohlfarth: Why boilers are still a great heating source

A tale of educating young minds.

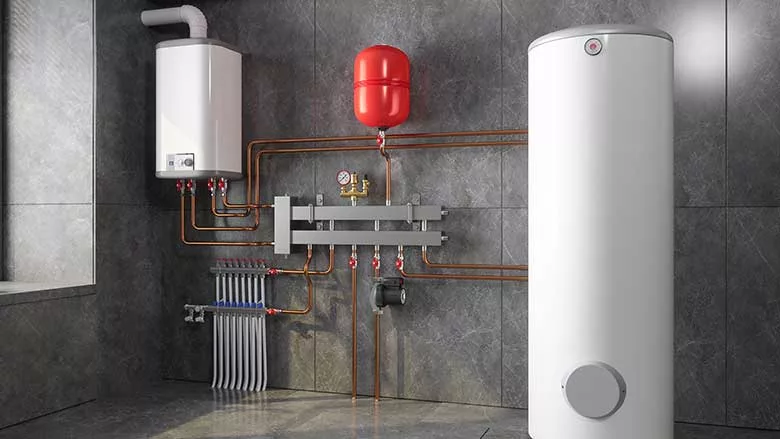

Image courtesy of onurdongel / iStock / Getty Images Plus.

I was teaching a class of steamfitter apprentices about boilers.

"Boilers? Nobody uses them anymore," one apprentice yells out.

"They are still used and, in my opinion, are the best type of heat there is," I say.

Rolling his eyes, he says, "It's old technology, not very efficient, and not green at all."

"Perhaps you can tell the class why you think they are still a viable option for heating," the regular instructor suggests. I smile.

"According to the ASHRAE HVAC Applications Handbook, the estimated life of an air-to-air heat pump or a rooftop unit is 15 years while a boiler life expectancy is between 24-35 years, depending on the boiler type. So, you will install two heat pumps or rooftop units for every boiler. Where do you think those old units will end up?" I ask the class.

“You want to use a system with R410A? Have you seen the price of it lately? The production has only dropped by 10% and the price is already spiking. Imagine the cost of it next year when the production drops from 90% to 60%. A hydronic system uses readily available, safe and affordable water," I say.

"How do you find refrigerant leaks?" I ask.

"With a leak detector," one apprentice says.

"Dye," another chimes in.

"Refrigerant leak detection is time-consuming. What if I told you that leak detection for a hydronic system can be done in minutes and cost almost nothing?" I ask, and they scoffed.

Pointing to the ceiling tile, I ask, "If a pipe was leaking above the ceiling, how would you know?"

"It would stain the ceiling tile," the once smug apprentice smiles.

"No expensive testing equipment needed. Just look at the ceiling tile," I say.

"What is the head pressure on an R410A unit?" I ask

"About 400 psi," someone calles out

"Exactly, a hydronic system pressure is about 12 psi for a two-story building. If the pipes burst on a refrigerant tube in this classroom, it could displace all the oxygen while a hydronic pipe leak would wet the ceiling tile and possibly the floor," I observed.

"What about cooling? A boiler can't cool a building," someone yells. They were a tough group.

"You're correct. A boiler provides an incredibly comfortable heating source, and although it doesn't provide cooling, it can be used for heating domestic water, snow melting, pool heating, towel warming, space heating, and, most importantly, for making beer," I say. Let me ask you a question. When you purchased your home stove, did you ask the salesperson if the stove would keep your beer cold?" I ask, and they smiled.

"A boiler uses fossil fuels, and that affects the environment. A heat pump doesn't," another person says.

"Great point. Did you know that most electricity is generated using fossil fuels? According to the U.S. Energy Information Administration, 38% of electricity is generated with natural gas and 22% coal. Nuclear makes up 19%, and the rest, 20%, is generated by renewable sources such as wind, hydro and solar," I explain. "Let's pretend you want to replace your 20-year-old gas boiler with a new one. Not because it's not working but because you want a more efficient system. You look at three options. The first is a non-condensing boiler rated at 82% efficiency, the second choice is a 95% efficient condensing boiler and the last is an air-to-air heat pump. The boilers will be connected to your existing gas pipe.

"Your first thought is to use an air-to-air heat pump because it is better for the environment,” I continue. “We'll pretend you didn't know that fossil fuels generate the most electricity. You and your spouse don't even mind that the line sets will look like something out of Stranger Things on your outside wall or the estimated life of the new system is 15 years.”

Did you know that according to the Office of Fossil Energy and Carbon Management (bet you didn't know there was such a department), the average efficiency of a coal-fired plant is about 33% efficient? After generating the electricity, we must transport it to your home. The average energy lost through transmission is about 6%. So, if you choose to use electricity to heat your home, the gas you were going to use to power your boiler is now 27% efficient coming to your home. That same gas could be used in a boiler, and you would be between 82% and 95% efficient.

“Which is greener?" I ask.

Another reason to consider boilers for space heating is comfort. When you walk into a commercial office space, try to count how many space heaters are being used. Each space heater uses the same energy as forty fluorescent light bulbs. Hydronic heating provides comfort, which increases the productivity of the office.

Another consideration is the price and availability of repair parts. If a control fails on your ductless system or rooftop unit, you have to go to the manufacturer to get the part. Most boiler parts can be sourced locally for much less money.

The U.S. Department of Energy has a study called, Field Performance of Inverter-Driven Heat Pumps in Cold Climates. It tested the heat output of air-to-air heat pumps. The study found that gas heat at 85% efficiency would cost about 39% less to heat than the heat pump.

"What about steam systems? Are they efficient?" I ask.

"No way," one yells.

"Really? The Empire State Building in New York City, built over 90 years ago, is 102 stories, 1,250 feet high, and heated with steam, and it was awarded a LEED Gold certificate for efficiency." I say.

"How?" one person asks.

"Steam zooms through a building at speeds up to 60 miles per hour without using a fan, compressor or pump. It uses steam pressure drop to push the steam around the building. Commercial systems estimate about 2 ounces of steam pressure drop for each 100 feet of pipe. If steam leaves the boiler at 2 psi and travels 200 hundred feet, the steam pressure would be one pound, twelve ounces, more than enough to heat a radiator.

I will close with a couple of statistics:

- A hydronic distribution system requires about 10% of the energy of an air distribution system;

- Water transfers heat 3,500 times better than air;

- A one-inch pipe can carry as many Btu as a 20-inch round duct;

- According to the U.S .Department of Energy, duct systems typically lose 25% to 40% of the air through duct leaks.

Still think boilers are old and inefficient?”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!