HYDRONICS WORKSHOP

John Siegenthaler: The 'net' effect

Air-to-water and water-to-water heat pumps are destined to claim increasing market share in future hydronic systems.

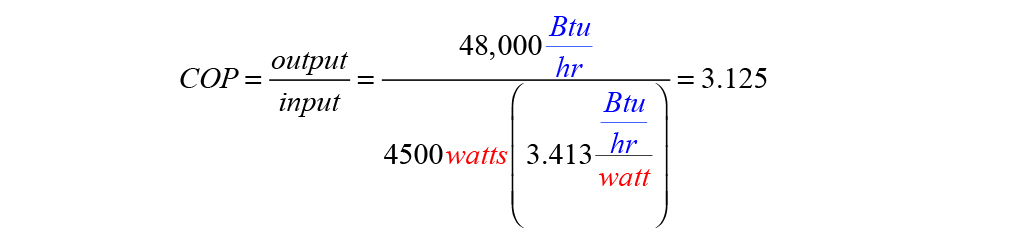

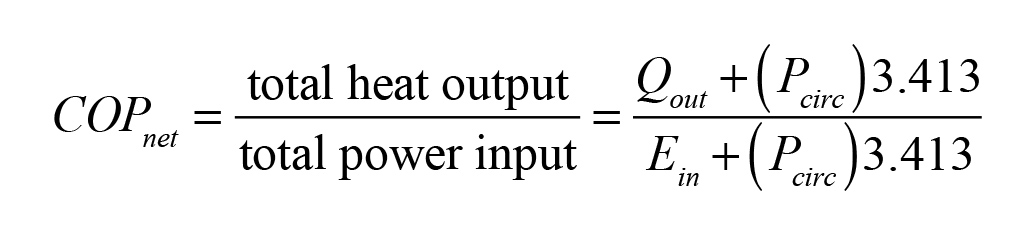

The Coefficient of Performance (COP) of a heat pump is essentially the same concept as the thermal efficiency of a boiler (e.g., the desirable output divided by the necessary input). For a heat pump, this would be the rate of heat output from the heat pump divided by the rate of energy input (as electricity) to operate the heat pump.

Consider, for example, a heat pump that releases 48,000 Btu/h to the load, while drawing 4,500 watts of electrical power. Its COP could be calculated as shown in Formula 1.

The number 3.413 in the lower part of the fraction just converts watts — the common unit for electrical power — into Btu/h. The units of watts, shown in red in two locations in Formula 1, cancel each other out. So do the units Btu/h, shown in blue. This makes the COP a “pure number” (e.g., without any units).

One can think of the COP of a heat pump as a multiplying factor. The energy output rate of a heat pump is the energy input rate multiplied by the COP. It can also be thought of a multiplier for the rate of heat output from the heat pump relative to the rate of heat output from any electrical resistance heater operating at the same input wattage.

The higher the heat pump’s COP, the greater the rate of heat output for a given rate of energy input. Or, stated in other terms, the higher the COP, the lower the electrical energy input for a given rate of heat output. Maintaining operating conditions that allow for the highest possible COP is a foremost design consideration when applying any heat pump.

‘Test Stand’ COPs

The performance data given by most air-to-water and water-to-water heat pump manufacturers doesn’t count the electrical power required to operate a circulator to move water through the heat pump.

For a water-to-water heat pump, which is typically used in a geothermal system, there are a least two circulators required: One to create flow through the geothermal earth loop, and another to create flow between the heat pump and a buffer tank or hydraulic separator. In some systems, two or more circulators are sometimes connected in series to move flow through an earth loop with high flow resistance.

For an air-to-water heat pump, one circulator is required to move flow between the heat pump and a buffer tank or hydraulic separator.

In either case, these circulators must operate whenever the heat pump’s compressor is running.

The system’s owner must pay for the electrical energy to operate the heat pump compressor, as well as to operate these circulators. There is no way around this. Thus, it’s appropriate to define a “net” COP that includes the electrical energy supplied to the heat pump’s compressor as well as any circulator(s) that must operate to shuttle energy through the heat pump. The net COP is a performance index that more accurately reflects the true operating cost of a heat pump in a hydronic application.

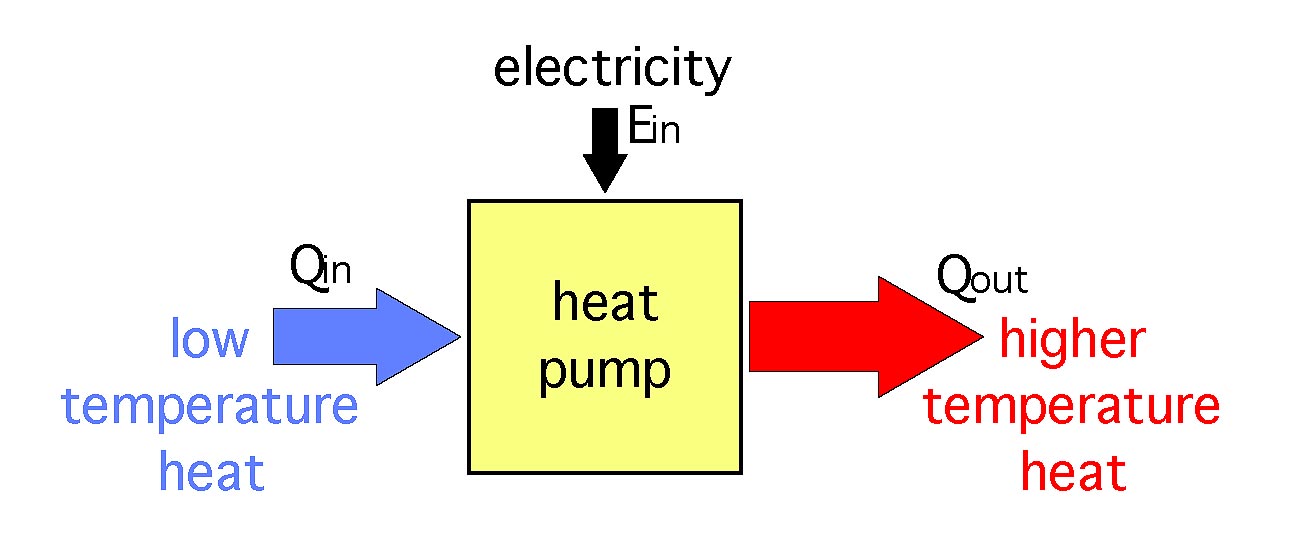

Consider the diagram shown in Figure 1.

This is a simple “energy balance” depiction of a heat pump. Energy from some lower temperature “free” source material (.e.g., ground heat or outside air) flows into the heat pump on the left. It’s represented by the symbol Qin.

Electrical energy flows into the top of the heat pump to operate it. It’s represented by the symbol Ein.

The heat output from the heat pump is called Qout.

Based on the principle of conservation of energy, and assuming steady state conditions, the rate of energy flowing into the heat pump must equal the rate of energy leaving the heat pump. Thus: Qout = Qin + Ein.

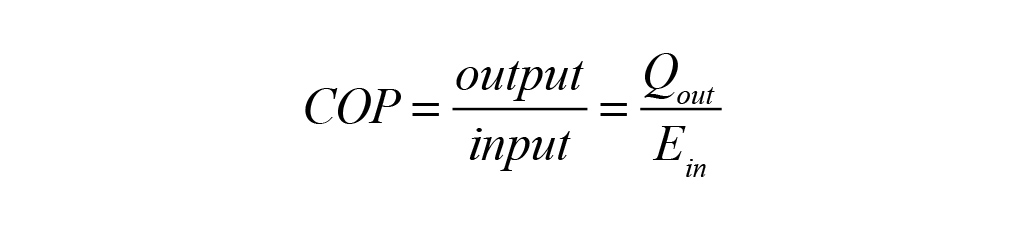

The heat pump’s COP is just Qout divided by Ein, when both are expressed in the same units of Btu/h.

Toss in the circulator(s)

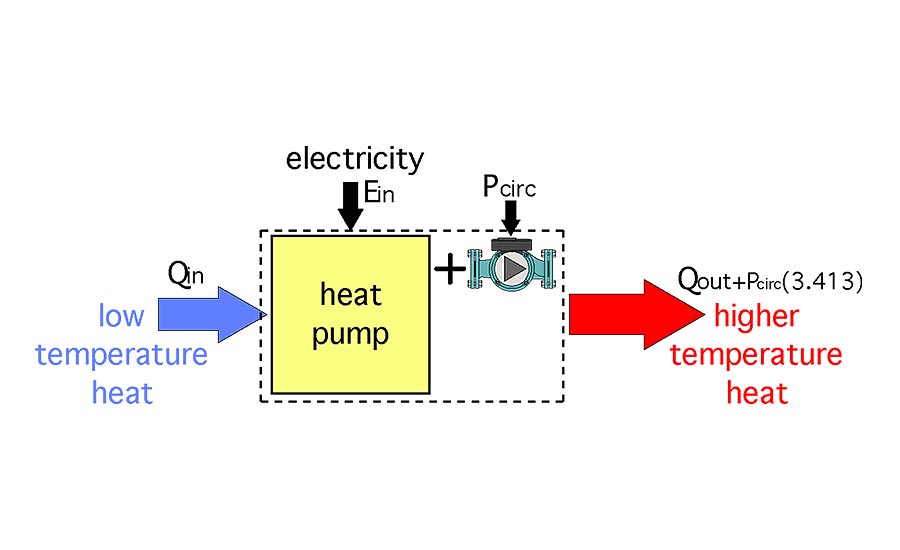

Next, consider the diagram in Figure 2, which represents an air-to-water heat pump and a circulator used to create the water flow that carries heat out of the heat pump.

Since the circulator is almost always mounted within the thermal envelope of the building heated by the heat pump, the electrical power it uses is ultimately converted to heat, and as such adds (slightly) to the total heat supplied to the building.

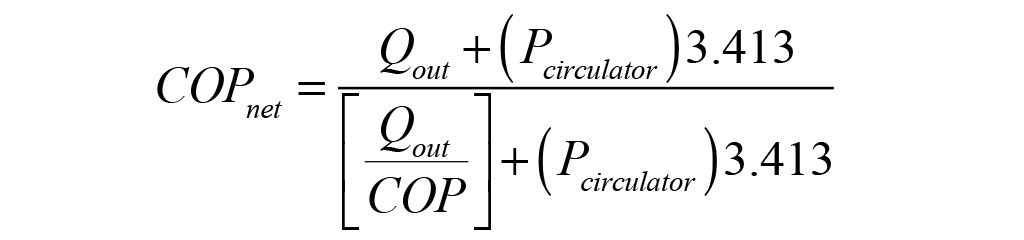

The net COP of the heat pump plus circulator, considered as a group, would be the total heat transferred to the building divided by the total electrical power input. It can be calculated using Formula 3:

By combining Formulas 2 and 3, it’s possible to express the net COP based on the COP of the heat pump as tested, the electrical power supplied to the circulator (in watts) and the heat output from the heat pump.

The net effect

The net COP is a truer indicator of the relative merit of a heat pump system, vs. the concept of a heat pump operating, in isolation, on a test stand. In the latter case, some “other device” is pushing flow through the heat pump as its being tested. The power to run that “other device” is not being accounted for. However, an owner doesn’t have the luxury of an “other device” pushing flow through their heat pump for free.

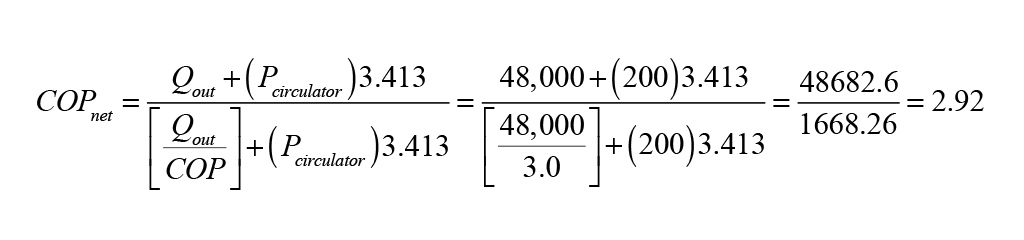

Let’s put some simple numbers into Formula 4. Consider a heat pump on a test stand that, at some specific operating condition, puts out 48,000 Btu/h, while maintaining a COP of 3.0. Next, consider the power input needed to run a load circulator in a real installation of this heat pump. If that circulator required 200 watts of power input, the net COP of the heat pump + circulator, considered as a group, would be:

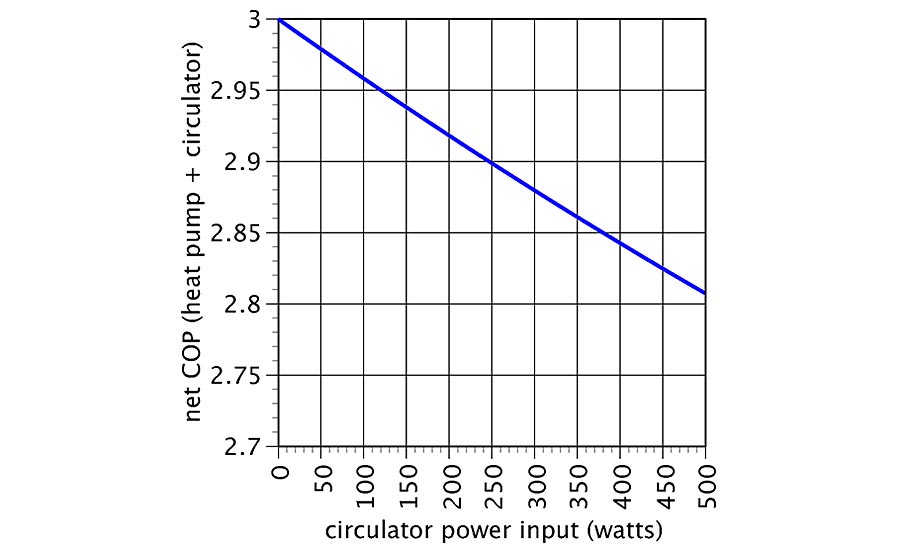

As the power input of the circulator increases and the other conditions (48,000 Btu/h output and COP = 3) remain the same, the net COP drops, as shown in Figure 3.

When applying Formula 4 to a water-to-water heat pump, be sure to include the power to all circulators that operate when the heat pump is running (e.g., those for the earth loop and between heat pump and either a buffer tank or hydraulic separator).

If you like spreadsheets, just set up a simple one for Formula 4 and “experiment” with different heat pump heating capacities, test stand COPs and circulator power inputs.

The takeaway

Although it’s probably intuitive to most readers, the greater the power input to the circulators required to operate a heat pump in a hydronic system, the lower the heat pump’s net COP, and thus, the more expensive the system is to operate.

Given the abundance of high-efficiency ECM circulators now on the market, it makes sense to select one that can supply the necessary flow rate through the heat pump (generally recommended as 2 to 3 gpm per ton [1 ton equals 12,000 Btu/h] of heating capacity), while operating at the lowest possible wattage. Doing so maximizes the net COP of the system and reduces the operating cost to the owner.

It’s also important to remember that the COP of a heat pump is very dependent on the temperatures of the source material and the load to which heat is being sent. The lower the load temperature can be, the higher the heat pump’s COP. Low-temperature high-efficiency distribution systems are always desirable when a heat pump serves as the heat source.

Both air-to-water and water-to-water heat pumps are destined to claim increasing market share in future hydronic systems. It only makes sense to apply them with “best-in-class” peripherals such as high efficiency circulators.

Formulas and figures by John Siegenthaler. Illustration: treety/iStock / Getty Images Plus via Getty Images.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!