Case Study

How to deliver large volumes of hot water quickly and intermittently

California-based nutraceutical manufacturer meets large, spiking hot-water needs with a combination tankless-and-tank system.

The six tankless water heaters that feed the nutraceutical manufacturer’s operations have a combined maximum input of nearly 1.2 million BTU per hour — more than enough to meet even the largest spike in hot-water demand from the plant’s various production stations. Photo courtesy of GreenHouse Digital + PR.

Proper water heater sizing in any application hinges primarily on user consumption within a given period. That much is probably obvious, even to someone who has never sized a water heater.

What complicates matters, especially in a large commercial application, is the cadence of that usage. Is demand relatively constant over the course of a day? Or does it spike from time to time? And if it does, how dramatic and frequent are all those spikes?

Solving for all those spiking variables ultimately calls for much greater engineering insight and creativity in water heater system design.

That was certainly the case recently for plumbing contractor Trent Eason, owner of Lancaster, California-based Priority Plumbing Solutions. With five employees and four trucks, Eason’s two-year-old firm provides a wide assortment of services to residential and commercial customers in Southern California — "from the largest construction and installation projects down to the smallest repair and maintenance work," according to his website.

Eason’s challenge in the case at hand: to help devise a new and more effective way to meet the varying hot-water demands of a local nutraceutical manufacturer’s production processes. The latter involve blending, encapsulating, and tableting various health and wellness products it sells in the United States and worldwide.

Because the company’s customers actually ingest these products, they are considered the equivalent of food. As a result, the manufacturer must adhere to comparatively high cleanliness standards. This is why the company follows the public health standards organization NSF, and why it became certified as a California Good Manufacturing Practice facility.

Not surprisingly, the above reality translates into a need for large amounts of hot water to keep all of this manufacturer’s machinery — blenders, tablet presses, encapsulation machines, and packaging lines, much of it made of stainless steel — in pristine condition. Daily hot-water usage totals thousands of gallons.

But here’s the twist, according to Eason:

"My customer uses a lot of water intermittently, not consistently. Lots of water all of a sudden, and then not much for a while after that. Their various machines are on a two-to-four-hour cycle. Depending on how those cycles align, usage tends to spike probably every three hours throughout a typical workday."

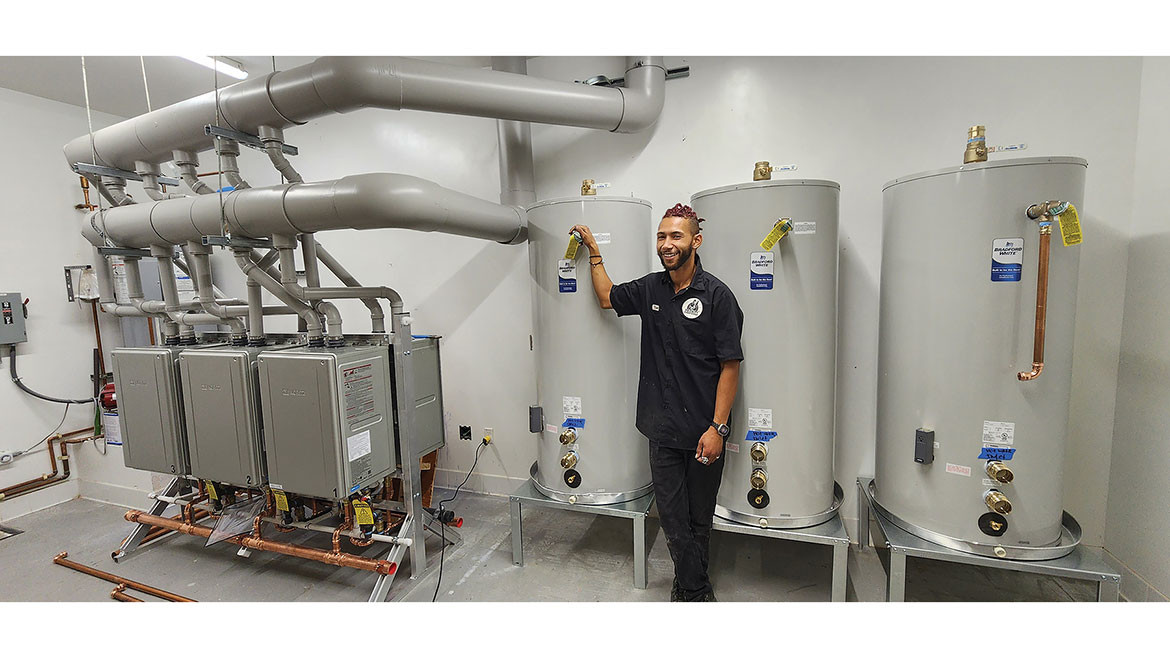

Travi Harris, Lead Technician at Priority Plumbing Solutions in Lancaster, California, is shown with the recently installed combination tankless-storage tank system, designed to meet the widely varying, daily hot-water demands of a nutraceutical manufacturer’s production processes in Southern California. Photo courtesy of GreenHouse Digital + PR

Time for a big change

This up-and-down demand is why a traditional water heating system is not workable for the manufacturer, notes Eason. But that’s precisely what it had until late 2023 in the form of an 80-gallon commercial electric water heater. This previous system performed adequately when the company first relocated to its current 220,000-square-foot operation in 2020. But as the business grew dramatically during the pandemic years and through 2023, its hot-water needs mushroomed as well, quadrupling over that span.

By early 2023, management recognized the need for a more innovative approach to generating hot water in sufficient quantities, one that would provide both a high volume and a quick recovery. Their solution combined tank and tankless technologies: a pre-assembled rack system comprising six condensing tankless water heaters from Noritz America coupled with three, 119-gallon storage tanks made by the Bradford White Corporation.

With maximum inputs of 199,900 BTU per hour, the Noritz units (Model NCC199CDV) can combine to provide a first-hour delivery of approximately 2,300 gallons of 120°F water, estimates Eason, whose five-person crew handled the installation.

And how quick is the system’s recovery? "It should be able to deliver that same amount of hot water within the next hour," says Eason, a 16-year plumbing industry veteran who has been installing and servicing tankless water heaters for nearly all of that time.

"We decided that combining a tankless system with the storage tanks would be the best way to deliver a large amount of hot water instantly within the first hour while also having a rapid recovery rate," he elaborates. "Even with maximum usage, none of their equipment should ever run out of hot water."

With maximum inputs of 199,900 BTU per hour, the six Noritz units (Model NCC199CDV) can combine to provide a first-hour delivery of approximately 2,300 gallons of 120°F water. Photo courtesy of GreenHouse Digital + PR

The boiler option

Priority Plumbing Solutions and its customer did briefly but seriously consider another possible solution: a gas-fired commercial boiler. "The issue there was the main water supply," Eason says. "We would have had to upsize the main to two and a half inches, as it runs from the city connection to inside the building and then to the mechanical room where the hot-water plant would sit.

"The piping would have been only a half-inch larger than what we eventually installed, but that extra half-inch represents a very big difference in the amount of water the entire system would need to contain."

As Eason notes, "A boiler would have involved more of everything: More water, more gas, plus different permitting and inspections. There are many more hoops my customer would need to jump through that the tankless water heating system did not involve."

Although the manufacturer was more experienced with boilers, the company found the advantages of a tankless rack system compelling. For one, there’s the Uniform Energy Factor of 0.96. This high efficiency, in turn, made the tankless system eligible for rebates offered by the State of California.

Eason’s customer also liked the simplicity of the maintenance of tankless and the operational redundancy of six water heaters. If one unit must go offline for servicing, the rest of the rack carries the load.

Wear and tear are also minimized by not having the units fire in the same sequence every time there is a demand for hot water. Nor are all six operating round the clock, but only at a level sufficient to meet present demand. Then again, if the situation calls for it, all six can fire at once, making the recovery super-fast.

Before making a final decision to go tankless, says Eason, "My customer did quite a bit of research and concluded this type of innovative system was a little more where the industry is headed, especially from the standpoint of efficiency and ease of installations.

"I know many people are moving from gas to electric," he continues, "but staying with electric would have been really difficult for their application. The company is using way less electricity now than it did with the old boiler, and its fuel costs are lower with gas.

"As complex as it might look, it’s a pretty simple system, and so was their decision to go with it."

Shown here, the manufacturer’s previous hot water system, an 80-gallon commercial electric water heater, performed adequately when the company first relocated to its current operation in 2020. But as the business grew dramatically during the pandemic years, its hot-water needs mushroomed as well, quadrupling over that span. Photo courtesy of GreenHouse Digital + PR

No downtime, please

One of the biggest attractions of the combination system Priority Plumbing Solutions proposed was the ability to avoid any production downtime during the changeover from the electric boiler to the tankless rack. Indeed, this was more than an attraction but an absolute must, says Eason. "Their operation cannot be without hot water for any length of time."

The entire installation spanned several months in the fall of 2023, as the Priority Plumbing Solutions crew installed all the piping required by the new system. This work included an entirely new, 1¼-inch gas line and an upsized cold-water supply: from 1¼ inches the old electric water heater used to the new 2-inch line. The team also had to create a larger supply-and-return loop connecting the mechanical room with all the production stations.

But because the tankless rack arrived fully assembled and ready to hook up, Eason and his colleagues accomplished the actual switchover from the previous system in a single weekend after production had shut down. "On Saturday, we did the changeover," he recalls. "On Sunday, a Noritz engineer helped fire up the water heaters and commission the rest of the system."

Once production began again on Monday, according to Eason, the stations were already enjoying all the hot water they needed. "At no point did the operation have to wait for hot water."

Eason calls out the water heater manufacturer for special praise: "Not only did Noritz participate in the startup, but they also walked the facility at the outset, learned the operations and their needs, and assisted our own team during the design phase. Their product and application knowledge helped guide us throughout. It was good to have them on board."

Since its commissioning in October 2023, the new combination tank-and-tankless system has been "performing as designed," reports the installer. "My customer has told me that whenever they have experienced their big spikes, the system has fully responded and then recovered just as quickly."

Eason cites one final but equally critical strategic consideration for the manufacturer in its move from electric boiler to gas-fired tankless water heating: ready scalability.

"These systems are designed to be modular and scalable to support operational growth," he explains, adding that his customer’s maximum daily gallonage of hot water used is approaching five figures.

"Even if their usage continues to rise, adding two tankless units and a fourth storage tank could be done quickly and easily without the costly ordeal of tearing apart the entire system.

"If they go that route, we will help them innovate again, and they will be just fine."

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!