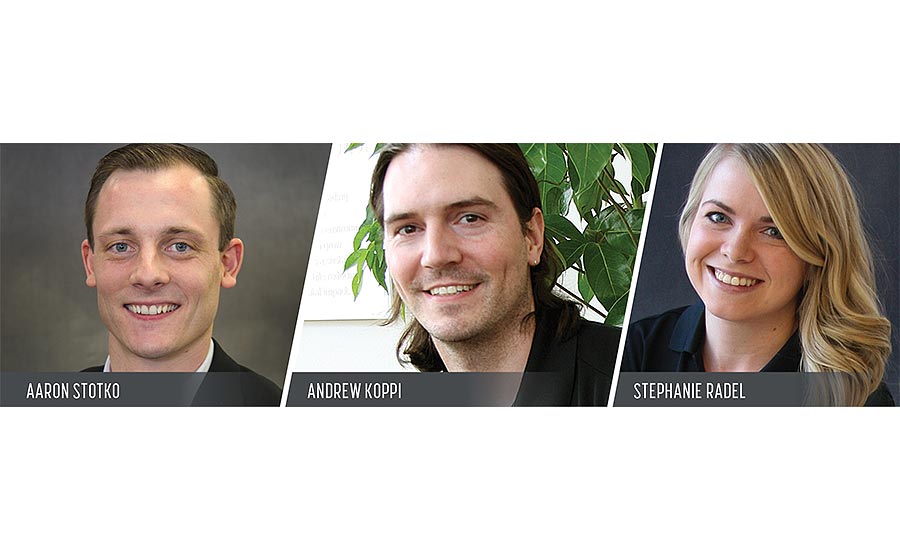

PM Profile: Uponor's Aaron Stotko, Andrew Koppi and Stephanie Radel

Uponor Unveils Complete Polymer Solution for Commercial Projects

Uponor PP-RCT (PolyPropylene, Random copolymer with modified Crystallinity and Temperature resistance) has higher temperature and pressure ratings than PP-R pipe, as well as lower levels of expansion and contraction.

Using the latest design and estimating tools, the Uponor team of designers and project managers offers a deep menu of design and construction services at no charge, including: square-foot budget estimations, material take-offs, piping material cost comparisons, design development, radiant heating and cooling loop layouts, and pipe sizing and load recommendations.

Using the latest design and estimating tools, the Uponor team of designers and project managers offers a deep menu of design and construction services at no charge, including: square-foot budget estimations, material take-offs, piping material cost comparisons, design development, radiant heating and cooling loop layouts, and pipe sizing and load recommendations.

Using the latest design and estimating tools, the Uponor team of designers and project managers offers a deep menu of design and construction services at no charge, including: square-foot budget estimations, material take-offs, piping material cost comparisons, design development, radiant heating and cooling loop layouts, and pipe sizing and load recommendations.

Using the latest design and estimating tools, the Uponor team of designers and project managers offers a deep menu of design and construction services at no charge, including: square-foot budget estimations, material take-offs, piping material cost comparisons, design development, radiant heating and cooling loop layouts, and pipe sizing and load recommendations.

Uponor North America launched its new Complete Polymer Solution for commercial-piping applications in the U.S. The platform for this important announcement was a 90-minute virtual event for customers, specifiers, installers and other buying influencers in the commercial plumbing and mechanical field.

The online unveiling included the official launch of two important initiatives: Uponor’s new PP-RCT mechanical piping system for commercial HVAC projects; and the new Uponor Construction Services, offering enhanced, professional estimation, design and building information modeling (BIM) services to support the design and installation of plumbing and mechanical piping systems.

Plumbing & Mechanical sat down with Aaron Stotko, senior manager, commercial segment; Andrew Koppi, manager, construction services; and Stephanie Radel, manager, construction services, to discuss the two new offerings and what it means for Uponor as well contractors, engineers and distributors.

We also spoke with Uponor North America President Bill Gray.

PM: Do you see this space as a growth area for your company?

AS: Absolutely! The polymer space, in general, and mechanical applications, specifically, is a huge growth opportunity. We know that a very small fraction of all hydronic piping projects are completed with polymers. So even with commercial markets contracting in 2021, there is a long runway for polymers to grow, allowing Uponor to increase share. Additionally, as the market rebounds in 2022 and beyond, it’s going to be hungry for solutions that increase productivity to help keep projects on schedule and on budget.

PM: What would be the best applications for it?

AK: There are many applications, but if I were going to say what the center of the bull’s eye would be, it would be wet HVAC systems. So condenser water, chilled water, cooling towers — that’s where we see the best benefit for PP-RCT. There are other applications, such as processed waters, chemical transport and compressed air. But if I were going to pinpoint one, it would definitely be the wet HVAC systems.

PM: Can you give an overview of a project using PP-RCT?

AS: The Utah Valley University (UVU) pedestrian bridge snow-melt project [Orem, Utah] speaks for itself. In that project, the contractor was looking for a solution that minimizes negative impacts to the overall site conditions. In that case, it was a bridge spanning across a freeway where there were requirements that needed to be adhered to for that job. When you hear the customer talk about how PP-RCT provided benefits for his business and in their build strategy for mechanical systems, that will continue to be a theme as more and more projects transition from those incumbent metallic materials over to polymers.

PM: What are the benefits of PP-RCT?

AK: On the engineering side, we have the weight reduction of the material versus carbon steel. That lends itself to the structure of a building. Most engineers have to account for the weight, not only of their equipment, but also of the piping itself and the piping with water. PP-RCT being 70% to 80% less weight than carbon steel can help with the structural requirements to transport the water through the building. Additionally, there’s no corrosion, no rust, no scale and no buildup with PP-RCT like they would have with metallic piping.

With metallic piping, engineers know, even if they’re chemically treating it properly, they’re still going to get that buildup over time. With PP-RCT, it’s a homogenous product, so nothing will stick to the inside. That means the flow rates they’re expecting on day one will be there on day 5,000 and beyond.

The message to a contractor is similar, but just a little bit different. When I talk about lighter weights from a contractor standpoint, that translates into safety. It means fewer job-site injuries from lifting heavy materials and equipment.

Additionally, the need for heavy equipment starts going down. With a big pipe, contractors may still need some equipment, but it might be less equipment. Or, instead of a crane, they might be able to use a service elevator. I worked on a project in Cleveland where they could utilize a service elevator versus a crane, and it saved them weeks’ worth of not only labor but also money. I hammer that home with contractors.

The lighter weight also benefits the distributor. They can replace the carbon steel they’re selling with PP-RCT. It’s going to require fewer personnel to move it around. And now, they can go out and sell a solution versus just a commodity.

I used to work for a distributor for 10 years before I got into the manufacturing segment, and distributors are looking for products to help their contractor customers. If they can bring in something innovative that can help a customer’s bottom line, it will help their bottom line as well.

PM: Can you talk about any hurdles you’ll need to overcome with this?

AS: Uponor is in the business of overcoming hurdles. We brought PEX to the North American market and have made that mainstream. We’ve displaced copper from residential applications, and now we’re doing so in domestic water for commercial applications. And, we will lead the way in the mechanical space as well.

We feel we have superior products along with services and support to help our customers through each stage of the construction process. We also have the right network, which includes our manufacturer representatives, our factory sales teams, our partnerships and our key distributors, to make that change in the marketplace. We are in position to be quite successful and move the entire market in a direction that consists of more polymer solutions.

PM: And how is Uponor, with that network, reaching out and adapting with this COVID-19 setting?

AK: We are offering everything from a virtual online training module all the way through job-site support. We know jobs are still happening, and we will get out there and get hands-on with customers as needed. We’re also offering in-person meetings — following the proper safety protocols — and virtual meetings/lunch-and-learns.

AS: Uponor Academy Online has significantly expanded over the past year to offer a robust virtual training program for plumbing, fire safety, hydronics and radiant. So whether in person or virtually, we have the vehicles and platforms for our customers, where they can engage with Uponor and get the learning they need to be successful on their projects.

PM: Tell us more about the Uponor Construction Services offerings and how they benefit contractors, engineers and distributors.

AK: Uponor Construction Services is for engineers, mechanical contractors and distributors who use our services. We’re a partner, so we want to be an extension of their organizational team. We offer a comprehensive service offering, which includes takeoffs through design developments, evaluations and load calculations, and continues through plan set and offering the models. We can integrate into any stage of a project and offer the services the customer is looking for when they engage us or based on their comfort level. In addition, we also have expanded our organization into BIM services, which gets into modeling and coordination, as well as onsite services, in addition to our sales teams. One of our goals is to stay on the forefront of that technology. We’re looking at software programs, such as Autodesk ReCap and BIM 360, in helping to connect the dots for our customers.

SR: We use Trimble AutoBid Mechanical for all our estimates. We have a database for that as well we can integrate into, so anyone using it can take our database and have everything we built. We have all content for Revit, including RBT and ITM. So, whatever they’re looking to do, whether it’s design, creating a nice model or all the way through coordination and creating spool drawings, we can do that for the customer. We also use AutoCAD, which works for the engineering team, HydroCAD for the fire sprinkler team and Navisworks for coordination, as well as MC. Many of our distributors use some of the software as well. Sometimes they’re helping the customers do some of that design work or some of that takeoff work. They can either do it themselves or send it to us, and we can help that distributor.

AS: The most compelling value for Uponor Construction Services is with the contractor, but there is value at the distributor, engineering and ownership levels as well. Mechanical contractors are competing for projects every single day, and they don’t win every project they touch. They might have win rates that are 5% to 20%, so there’s a lot of work that goes into bidding projects they may never actually win. And that costs them money. When a contractor is looking at a 3% profit margin, and they have a $50,000 sunk cost, they need to sell $1.7 million in revenue to make up for that and maintain that margin. Any way Uponor can reduce those sunk costs, we want to help.

Wherever they are in the project, we can help. If they are bidding a project, we can provide an entire takeoff that includes labor rates and all the items they need to execute their bid. There are also times where contractors are not familiar with how to size these systems. After all, PEX and PP-RCT have different flow characteristics (different diameters and much smoother pipe walls) than the materials that have been used for years. This is where we can really provide value. Our systems and design team ensures each pipe segment and fitting has the right hydraulic properties to execute the job without oversizing, which can lead to higher material and installation costs.

If they’ve already won the project and are doing prefabrication, contractors need to have content to design and create the spools that ultimately will be built in their fabrication facility. Looking further out in the building’s lifecycle, it will likely need to be reconfigured and renovated. Uponor’s BIM Services has the ability to get onsite and scan the existing structure and mechanical systems, creating a current virtual model to start working from. So really, Uponor Construction Services is one of our biggest assets. There are tremendous opportunities for contractors to really step in and get the right level of service for where they are, whatever phase they’re at with their projects.

This leads us to another benefit for the contractor and distributor. Because we’re able to provide an accurate bill of materials, the contractor doesn’t have to go to a distributor and say, “Hey, I’m looking at converting this project,” or “I’d like an Uponor material list.” If that comes over to the distributor from the contractor in copper, what’s the distributor supposed to do? Do they just make everything the exact same size as copper? There actually might be opportunities to use smaller-diameter packaging. For the distributor to have to figure that out is not really a position where they’re getting the right return on time. And the contractor is ultimately not going to get an optimized bill of material list, either. By helping the contractor out, it also benefits the distributors as well.

For the engineer, we offer several services, such as custom spec writing and radiant calculations. For example, we can perform finite element analysis (FEA) for radiant panels. So, if a customer is considering radiant heating and cooling, we can evaluate how much heat gain the radiant slab can take on in cooling and vice versa for heating and snow-melt applications. This allows the client to understand the performance of the radiant system so they can determine the sensible load they are able to reduce from the air side, which can oftentimes reduce the amount and size of the other HVAC components. Uponor Construction Services can calculate all of that information and provide those calculations back to the engineer.

We also have a self-service side of Uponor Construction Services with our online calculator and our BIM and CAD content. Our content is for both the engineer and the contractor. Our online calculator is a powerful tool that makes it easy to determine the fixture unit range for a given pipe diameter based on a few simple inputs. The calculator also features a heat-loss tab that generates pipe heat loss/gain data along with the surface temperature of the pipe or insulation. This can help identify insulation requirements, making it easy to determine if or how much insulation is needed to mitigate condensation.

PM: Do you have anything else you’d like to add?

AS: We’re really excited about coming into the market with a comprehensive solution for mechanical piping systems. We have a hybrid PEX and PP-RCT polymer solution that really allows our customers to optimize their productivity from a material standpoint. Then, when we partner that with Uponor Construction Services, our training options, and our warranties, it really makes a big difference for our customers. Copper has a one-year warranty and doesn’t come with much support. We’re really looking to establish that deep partnership with our customers and tell a compelling story about why this makes sense for them to leverage Uponor.

AK: Looking at just those silos, the engineer, the contractor, and our distributor partners, the real benefit that Uponor brings to this world would be on commercial projects. Typically, you see this work separate with two and a half inches and up being carbon steel and two inches and down being copper. Now there is one trusted source that can offer a complete polymer solution for both ends of that spectrum. On the two inch and down, we have PEX, a product that will accommodate that share shift from copper. With PP-RCT, we have the ability to get into those larger diameters to offset that carbon steel market. It’s one company and one warranty holder. There are other polypropylene players in the market, but they all use outside insurance agents for their warranties. Everything with us comes through one source. For the contractor, there’s a lot of peace of mind knowing Uponor stands behind its products.

SR: We’re very excited for 2021 and the new opportunities we have for our customers. By launching the new PP-RCT product line and Uponor Construction Services, we’re ready to go out there and train, we’re ready to take on new projects, and we’re really ready to see the new opportunities and partnerships this can all bring.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!