Tips on maintaining high-efficiency boilers

Protect your customer’s investment.

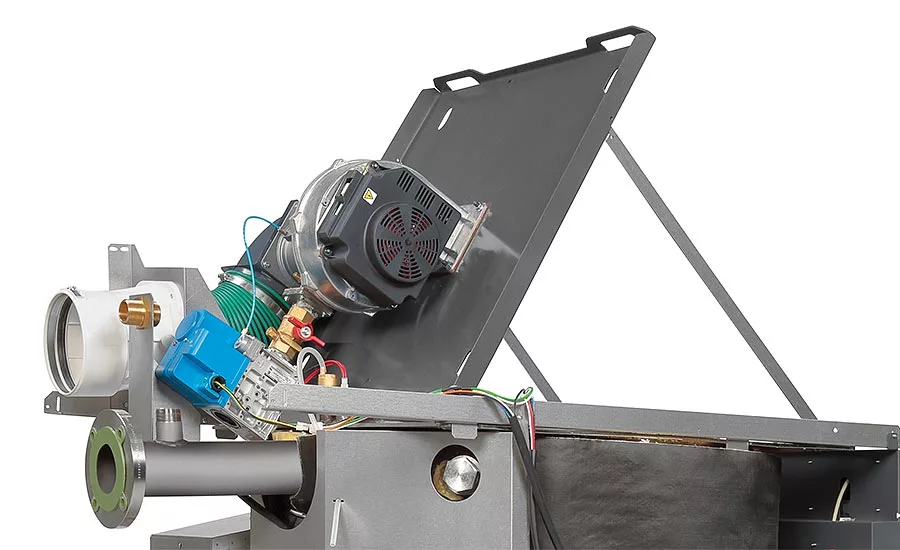

A hinged cover plate on a boiler can be propped open like the hood of a car, granting quick access to the center of the boiler, including the burner and firetubes, for inspection or cleaning.

Boilers should be inspected and serviced by a professional installer or technician at least once a year. The intense environment inside a high-efficiency boiler should be monitored and serviced to maintain peak efficiency.

Popular high-efficiency boilers tend to be more expensive at installation, but lower utility bills pay customers back over time. In fact, the U.S. Department of Energy estimates that replacing an older boiler system with a new, high-efficiency one can cut fuel bills by up to 40%. However, to protect that investment, high-efficiency boilers need to be properly maintained, just like you would with a car.

Two key parts of a boiler are the heat exchanger and heat engine. Put simply, the heat exchanger transfers heat from the combustion process into the water that’s circulated through the building. The more energy the heat exchanger can transfer, the more efficient the boiler is. High-efficiency boilers extract heat so efficiently that the flue gases leave the boiler at temperatures low enough that they actually condense inside the heat exchanger.

Why high-efficiency boiler maintenance is important

High-efficiency boilers especially benefit from the right maintenance because of the technology inside — some achieving upwards of 95% efficiency. The intense environment inside a high-efficiency boiler should be monitored and serviced to maintain peak efficiency and keep things comfortable:

- The combustion and extreme temperatures created in the heat exchanger in order to heat the water can lead to residue;

- Rapid temperature changes form condensation and combustion byproducts, which can lead to drainage clogging;

- A byproduct of the combustion process can mix with condensate and raise pH to damaging levels;

- The repeated firing of the boiler flame wears on the flame rod sensors the boiler depends on;

- Air intake pipes can accumulate debris and can stall the system;

- The air intake pipe or vent could be clogged causing your system to occasionally stall out or lock out, which will leave you without heat or hot water; and

- Water levels must be maintained properly to prevent permanent damage.

Routine boiler inspection checklist

Whether you’re a technician or a building professional, there are routine steps you can take to keep a high-efficiency boiler performing. Some of these you can do in passing, others are more involved and can be done less frequently. If you notice any issues, we highly recommend you call the contractor who installed the unit for a solution. Here are some of the inspection and maintenance steps to take at your customer’s home or facility:

- Check the air vents and flues for any blockage and clear, if able;

- Look at the pressure gauge to ensure the water level is staying about the same — system pressure declines as water is lost;

- Keep an eye out for dripping water, it may indicate pressure issues;

- Clear the area around the boiler. Boxes, bags and other items should be moved away from the boiler to allow it to breathe. Always keep chemicals such as solvents and cleaners away from the boiler;

- Check piping for any signs of leakage or deterioration; and

- Examine the condensate drain line, PVC fittings, drain system and drain trap for blockages.

Book an annual boiler service appointment

Boilers should be inspected and serviced by a professional installer or technician at least once a year. Even if a customer has taken good care of their high-efficiency boiler, the trained eye of a professional can address smaller issues and prevent bigger more expensive repairs or replacement — again, to protect their investment. Each contractor is a little different, but during a tune-up or maintenance visit, technicians should typically:

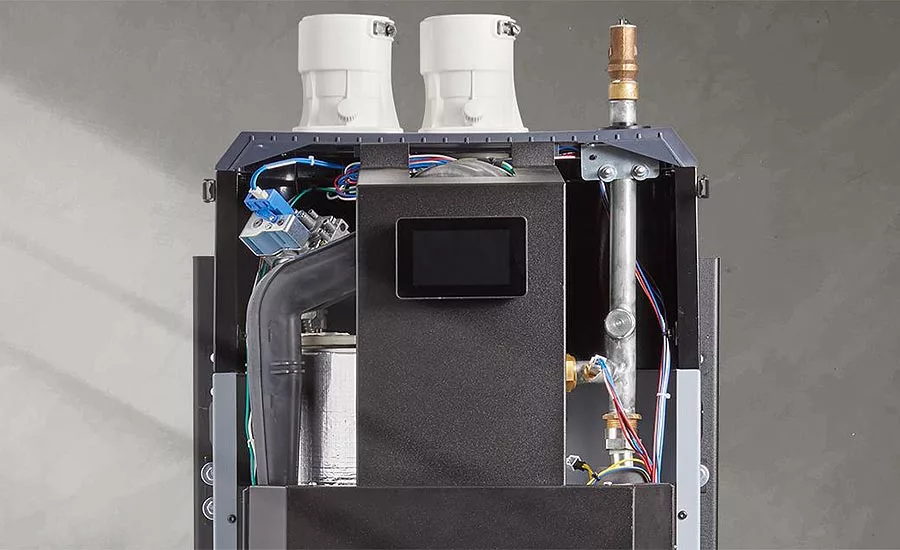

During a tune-up or maintenance visit, technicians should clean and inspect the heat exchanger for wear and tear.

- Clean and inspect the heat exchanger for wear and tear;

- Check and clean the burner assembly;

- Test the low-water cutoff;

- Ensure all electrical wiring is intact and joint/pipe connections are secure;

- Test water pH levels to make sure they are in a safe range;

- Clean, flush and inspect condensate systems;

- Make sure the system operates properly, by testing and cleaning sensors, ignitor and burner assembly;

- Check the venting system for deterioration, corrosion or blockage;

- Check settings and test the safety and operating controls;

- If system water is dirty, power flush the system piping to maintain efficient water flow; and

- Check for correct boiler operation once the boiler has been cleaned and examined.

Additional Servicing Tips

It’s best to service a high-efficiency boiler when temperatures outside are not too extreme and as close as possible to when the customer will turn the system on for heating season.

Servicing a boiler will make it more efficient. The unconstrained flow of air, water and power is critical to performance. Leaky and/or clogged pipes or air vents force the system to work harder than it needs to, negating efficiency.

Servicing hydronic system piping as well as the boiler are critical in maintaining the boiler’s efficiency. Dirty system water will not absorb as much heat energy as clean system water and will degrade the heat-exchanger’s ability to transfer heat energy into the water, therefore reducing its efficiency. Clean system water and piping maximize the boiler’s efficiency.

Also, through the season, combustion byproducts will deposit on the heating surface in the heat-exchanger, preventing some heat energy transfer into the system water. Removing these byproducts annually, before the heating season, will restore the boiler to peak efficiency.

High-efficiency boilers are relatively new in the grand scheme of heating equipment. Servicing them on a regular basis will help ensure their longevity for years to come.

To learn more about high-efficiency boilers at Weil-McLain, visit www.weil-mclain.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!