John Siegenthaler: Three inputs, one output

Multiple strategies for heating domestic water.

I recently designed a system for my daughter’s new home with a water-to-water geothermal heat pump as its main heat source. The intent was to provide space heating and domestic hot water with heat from the heat pump.

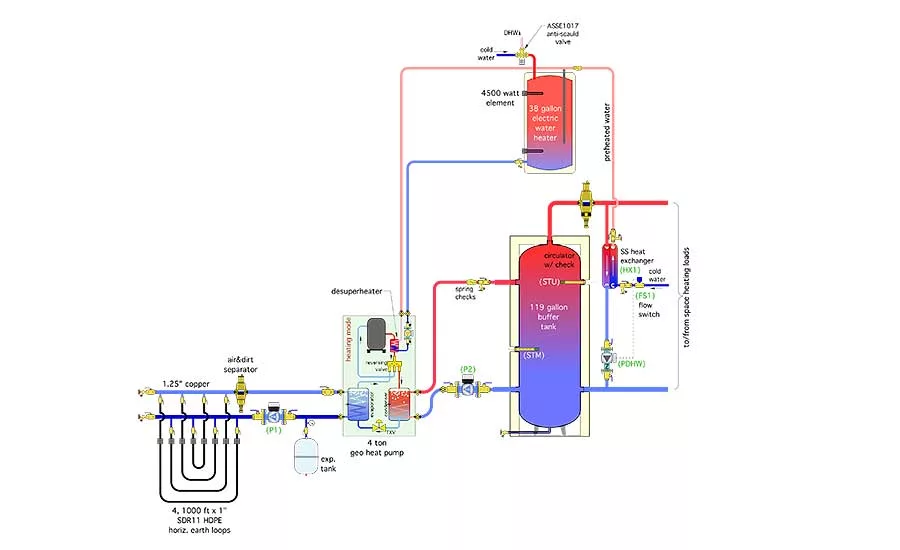

The space heating distribution system, which was described in the January 2020 Hydronics Workshop column, was extensively zoned. There are seven individual zones with a combined design load of only 29,700 Btu/h. Some of these zones are single panel radiators with design outputs in the range of 1,400 Btu/h. To avoid short cycling the heat pump, we planned the system around a 119-gallon buffer tank. A portion of the system’s piping is shown in Figure 1.

The heat pump is equipped with a desuperheater, which is a small heat exchanger that receives hot refrigerant gas directly from the compressor. The other side of the desuperheater receives “cool” domestic water from the lower portion of a domestic hot water tank. Heat moves from the hot refrigerant to the domestic water as they pass through the desuperheater. After exiting the desuperheater, the refrigerant flows on to the heat pump’s condenser, where it transfers heat to “system” water. Warm water leaving the desuperheater flows back to a 38-gallon hot water tank. A small stainless steel circulator inside the heat pump creates the domestic water flow.

Grabbing Heat

When hot refrigerant gas leaves the heat pump’s compressor, its temperature is several degrees above the saturation temperature (e.g., the temperature at which the refrigerant gas begins to condense). This “extra” temperature above saturation conditions is called superheat, and it has to be dissipated from the refrigerant before condensation can occur.

A typical desuperheater transfers about 10% of the available heat in the refrigerant gas leaving the compressor to the domestic water stream. The remaining heat is transferred to the system water within the heat pump’s condenser.

In heat pumps equipped with a desuperheater, domestic water heating occurs whenever the heat pump’s compressor is running in heating or cooling mode. Some heat pumps turn off the domestic water circulator if the water temperature leaving the desuperheater climbs to 130° F.

In cooling mode, heat removed from the refrigerant by the desuperheater is heat that doesn’t have to be dissipated from the earth loop. This is beneficial in two respects: First, it’s “free” heat for domestic water, and second, lower ground loop temperatures improve the Energy Efficiency Ratio (EER) of the heat pump, lowering operating cost.

In heating mode, the energy transferred to domestic water by the desuperheater offsets what would otherwise be required from the electric resistance heating element(s) in the water heater. The COP associated with heat from the desuperheater might be in the range of 3.0 to 4.0. The COP of electric resistance heating is 1.0. A given amount of domestic water gets heated through a given temperature rise using a fraction of the electrical energy required by a standard electric water heater. Furthermore, the majority of this heat is coming from the earth, not being absorbed from the air inside the building, as would be true if a standalone heat pump water heater was used.

The percentage of the total DHW load that is covered by the desuperheater depends on many variables, including:

- What percentage of elapsed time is the heat pump running;

- How much domestic water passes through the electric water heater when the heat pump is running;

- What is the volume of the electric water heater;

- What is the thermostat setting of the electric water heater; and

- What is the heating capacity of the heat pump?

Systems with relatively large electric water heaters, relatively high DHW demands, lower temperature settings and heat pumps not grossly oversized for design heating loads will tend to allow a higher percentage of the total DHW load to be met be the desuperheater. However, short of monitoring a specific installation, or setting up detailed (minute-by-minute) software simulations with assumed loads and mechanical equipment performance, it’s hard to know what that percentage is.

When the Heat Pump is Off

One thing is certain, when the heat pump is not running, there is no heating contribution from the desuperheater. This is where another complementary strategy comes in.

The system includes an external stainless steel heat exchanger, DHW flow switch and circulator arranged into what I call an “on demand” water heating assembly. These components can be seen on the right side of the buffer tank in Figure 1.

This assembly allows heat stored in the buffer tank to be added to the coldest domestic water in the system. This transfer occurs whenever there’s a demand for DHW of 0.7 gpm or higher. As soon as the cold water flow rate entering the heat exchanger reaches 0.7 gpm, the flow switch closes its contacts. This turns on the coil of a relay, which in turn applies line voltage to a small circulator (labelled as PDHW in Figure 1). Heated water from the top of the buffer tank is routed through the primary side of the heat exchanger and back into the lower portion of the tank.

With proper sizing, the heat exchanger can lift the domestic water temperature to within 5° of the temperature entering the primary side of the heat exchanger. We used a brazed plate heat exchanger with 40 5-inch x 12-inch plates. It was sized to raise 50° domestic water to 95°, at a secondary side flow rate of 4 gpm, and with water entering its primary side at an average temperature of 100°, and a flow rate of 10 gpm. This “pre-heated” water then flows into the cold water port of the electric water heater.

The load reduction on the electric element in the tank or the desuperheater depends on the entering temperature of the preheated water. For example, if the heat exchanger raised cold domestic water from 50° to 95°, and the final de-sired water temperature leaving the tank was 120°, the heat exchanger would have imparted (95-50)/(120-50) = 0.64, or 64% of the total energy required to heat DHW.

It would be possible to increase this percentage by increasing the water temperature in the buffer tank. However, the warmer the buffer tank temperature, the lower the heat pump’s COP. Again, the “optimal” compromise between DHW preheating fraction and heat pump COP is hard to determine, theoretically. Small incremental adjustments of the settings, with some form of heat pump performance monitoring will hopefully be possible in the future to help determine optimal settings.

This on-demand domestic water preheating assembly could be used on hydronic heat pump systems where no desuperheater is present. One example is an air-to-water heat pump. It could also be used in combination with other renewa-ble heat sources with associated thermal storage tanks. Examples include solar thermal collectors, cordwood gasification boilers and pellet boilers.

The Last Resort

The “backup” heat source in this system is a 4,500-Watt electric element in the 38-gallons water heater. That tank is rated to provide a first hour DHW delivery of 54 gallons per hour, and a recovery of 27 gallons per hour assuming a 50° to 120° temperature rise, and thus absent any preheating effect. This is sufficient to assume the full domestic water heating load if the heat pump is off and awaiting servicing.

Domestic water heating takes advantage of the higher efficiency of contemporary heat sources operating at lower temperatures. If you’re working with hydronic heat pumps for space heating and cooling, and the building needs domestic hot water, you should leverage this opportunity.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!