How to properly size finned-tube baseboard heat emitters

Have a look at the rating tables for most finned-tube baseboard sold in North America and chances are you’ll see a footnote.

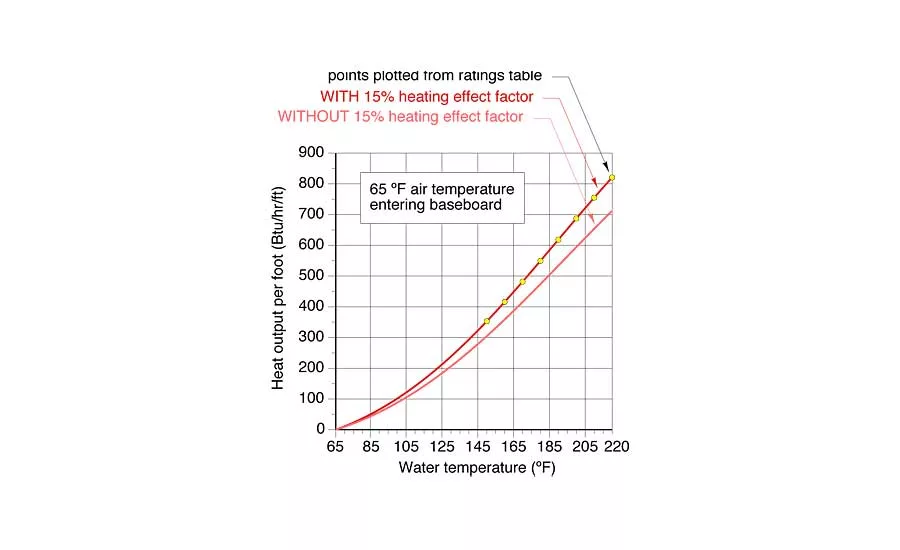

Figure 1 shows a comparison of typical residential finned-tube baseboard output with and without the 15% heating effect factor. Image courtesy of John Siegenthaler.

Figure 2 shows a screen shot of the Series Baseboard Simulator module from this software. Image courtesy of John Siegenthaler.

Have a look at the rating tables for most finned-tube baseboard sold in North America and chances are you’ll see a footnote under the table that reads something like this: “Ratings are based on active fin length and include 15% heating effect factor.”

So what exactly is meant by “heating effect factor?”

Here’s what the 2016 ASHRAE HVAC Systems & Equipment Handbook has to say on page 36.3:

-

“The generally accepted method of testing and rating baseboards in the U.S. is covered in the Testing and Rating Stand for Baseboard Radiation (AHRI 2005a);” and

-

“Baseboard ratings include an allowance for heating effect factors of 15% in addition to the test capacity. The addition made for heating effect must be shown in the manufacturer’s literature.”

The I=B=R / AHRI Certified Product Directory of 2009 states the following regarding the 15% heating effect factor: “All baseboards listed have been tested at the I=B=R Laboratory and ratings approved based upon these tests. An I=B=R Baseboard Rating is the Output, determined under the strict limitations and conditions set forth in the I=B=R Testing and Rating Standard for Baseboard Radiation, plus 15%. This added percentage is credited to the baseboard unit because this type of radiation is usually installed at low levels where maximum heating effect results.”

So what can be gathered from these statements?

-

The AHRI testing standard allows baseboard manufacturers to add 15% to the tested heat output ratings of their baseboards, provided that they indicate this in their published ratings; and

-

The 15% added output is credited to baseboard because it is usually installed in “low levels” where “maximum heating effect results.”

This still doesn’t explain the conditions upon which 15% adjustment is based, or how those conditions differ from those in which the baseboard is tested or typically installed. And for what it’s worth, have any of you ever seen finned-tube baseboard installed at levels other than close to a floor?

A long time ago

In the late 1980s, I had a long conversation about the heating effect factor with the technical director of the Hydronics Institute. We discussed the origin of the heating effect factor. He explained that when finned-tube heat emitters were first introduced, they were installed at the nominal top height of a cast-iron radiator. Apparently someone at the time discovered that moving the finned-tube element to just above floor level produced greater heat output, and apparently those writing the rating standard felt a 15% adder was justified.

The problem I have with this is that the baseboards are tested and rated based on 65° F entering air temperature. To achieve 15% output boost would require the air temperature entering the baseboard to be about 54° F (assuming 170° F water in the baseboard). While such low floor level air temperatures might have existed in homes during the middle of 20th century when the heating effect factor was “discovered,” these temperatures are not common in homes meeting current energy standards.

Based on this, the only technically supportable observation I can offer is this: Adding 15% to laboratory tested heat transfer values, based on the assumption of the baseboard being placed in abnormally cool locations, does not facilitate accurate sizing in normal applications.

So why does baseboard heating work?

After reading this you’re probably thinking: If the actual heat output from baseboard is 15% lower than the published ratings, why aren’t there more complaints about inadequate heat delivery? This is where things get interesting.

Think about a typical residential series baseboard circuit. It might have 3-6 baseboards, and several yards of uninsulated 3/4-inch copper tubing connecting those baseboards and completing the circuit back to the boiler. A 3/4-inch tarnished copper tube carrying 170° F water through a building space at 65º F loses about 46 Btu/hr per foot of length. Consider a baseboard circuit with 60 feet of bare 3/4-inch copper tubing operating at this condition. The heat loss from that bare tubing is about 2,760 Btu/h. That’s enough output to easily heat a typical bedroom on a cold day.

If this same circuit contained 35 feet of finned-tube releasing an average of 425 Btu/h per foot (assuming 170° F average water temperature and 65° F inlet air temperature), the finned-tube portion of the circuit would have a total output of 14,875 Btu/h.

The bare tubing in that circuit therefore releases about 18.6% of the heat output of the finned-tube in the circuit.

It’s my assertion that, in many heating systems, the heat released from bare copper tubing compensates for the lower-than-rated heat output of the finned-tube baseboard.

Confirmation

Years ago, my software partner Mario Restive and I developed a hydronic baseboard simulation program called HYDRON. It had a rather bland DOS user interface, but under the hood it used very detailed engineering equations to model the performance of series connected baseboards, including the heat loss of the tubing connecting the baseboards.

After making many runs of that software we found that the total output of uninsulated bare copper tubing connecting baseboards into a complete circuit was often in the range of 15% of the total heat output of the baseboards. This percentage would obviously go down for systems with minimal interconnecting tubing, and up for systems with lots of tubing.

The takeaway

Series baseboard circuits are common in North America, especially in basic residential systems. In most systems they provide comfortable heating. In situations where tubing such as PEX, PEX-AL-PEX, or Polypropylene is used to connect the baseboards, or where the interconnecting tubing is insulated, the heat loss of that tubing will be substantially reduced relative to the heat loss of traditional copper tubing. In such cases it’s prudent to select baseboards based on tested heat output rather than (tested +15%) heat output.

You can do this by dividing the I=B=R heat output ratings that include a 15% heating effect factor by 1.15, and then size the baseboard to the room’s design load.

Figure 1 (above) shows a comparison of typical residential finned-tube baseboard output with and without the 15% heating effect factor.

If the baseboards are connected in series, keep track of the water temperature drop from one baseboard to the next during the sizing procedure. There is software such as the Hydronics Design Studio that can quickly size series-connected baseboard taking this temperature drop and several other variables such as circuit flow rate, fluid type, and individual room temperatures into account. Figure 2 (above) shows a screen shot of the Series Baseboard Simulator module from this software.

As modern piping materials such as PEX tubing become more common for hydronic distribution piping, the heat output associated with traditional bare copper tubing will decrease. It will also decrease a lot in situations where either type of tubing is insulated. Some building codes now require this for any tubing run through an “unheated basement.”

My advice is to size baseboards based on a heat output per foot that does not include the 15% heating effect factor. The heat output from distribution piping can then be viewed as a safety factor.

I also urge you to size the baseboard around lower supply water temperatures, perhaps even as low as 120° F under design load. That baseboard is going to last a long time, easily outliving its first heat source. Sizing for lower supply water temperatures helps preserve compatibility with future low-temperature heat sources such as mod/con boiler or heat pumps. If limited by wall space, consider use of finned-tube with larger fins to achieve a given output at lower water temperatures. Remember this formula: Added emitters = added efficiency.

This article was originally titled “Divide by 1.15” in the March 2017 print edition of Plumbing & Mechanical.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!