AHR EXPO

AHR Expo 2026: Hydronics innovation focuses on practical execution

Prefabrication, data center cooling and hybrid systems dominate show floor.

AHR Expo 2026 took place in Las Vegas from February 2-4, with more than 50,000 in attendance.

The 2026 AHR Expo, held February 2–4 at the Las Vegas Convention Center, once again served as a barometer for where the HVACR and its aligning markets are headed. With more than 50,000 industry professionals on site and over 1,800 exhibitors, the show floor reflected an industry balancing near-term realities with long-term regulatory and sustainability goals.

Federal and state regulations slated for 2026, ongoing decarbonization efforts, and rapid technology development all shaped the conversation. But in plumbing, wet heat, and hydronics specifically, the dominant theme was execution; across booths, manufacturers focused on how systems are designed, packaged, installed, and serviced in the real world.

AHR Expo 2026 exhibit floor.

Legend Valve highlighted its LegendPress press-fit system across carbon steel gas and copper applications, underscoring the role of press technology in prefab-ready installations.

Images courtesy of Natalie Forster

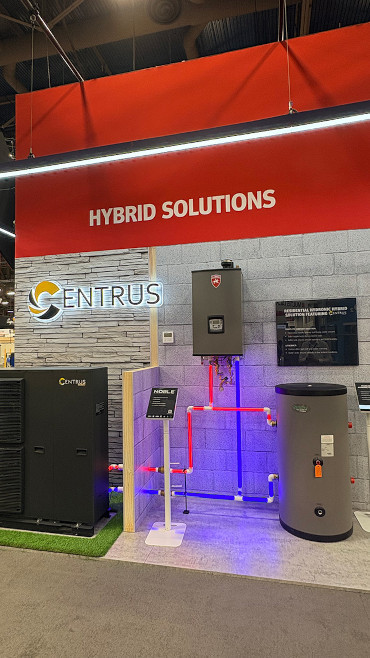

Hybrid systems move from concept to default

AHR Expo 2026 made it clear that hybrid systems are no longer an emerging idea; they are the answer to the ongoing balancing act of meeting decarbonization goals while being realistic about how much electrification the grid can handle.

Manufacturers emphasized systems that combine electric technologies, gas-fired equipment, and advanced controls. The messaging acknowledged emissions and efficiency goals while remaining realistic about grid capacity, climate variability, and application-specific demands.

Controls played a central role in this shift. At the Watts booth, tekmar displays focused on smart controls for residential HVAC and hydronics, including heat pump controls and diverting valve panels designed to manage multiple heat sources within a single system. The emphasis was on flexibility, which allows systems to stage, prioritize, and balance energy sources dynamically.

Hydronics and heating equipment at the Navien booth reinforced this trend, highlighting connectivity and diagnostic tools that simplify commissioning and long-term service. The takeaway was consistent across booths: hybrid systems are no longer transitional, they are becoming the most workable path forward.

Navien showcased hydronic and water-heating equipment integrated with digital interfaces, reinforcing the growing role of connectivity in system commissioning and service.

Taco Comfort Solutions’ TridentBoost packaged pressure boosting system reflects growing demand for factory-assembled solutions that reduce field labor and simplify commissioning.

A cutaway view of the Alta boiler from U.S. Boiler Company highlights factory-installed components and internal organization designed to simplify installation and service.

Weil-McLain’s Eco Hybrid Dual Fuel Hydronic System pairs an air-to-water heat pump with a boiler, highlighting hybrid strategies designed for performance across varying conditions.

Images courtesy of Natalie Forster

Hybrid hydronics gain validation across categories

Hybrid strategies were reinforced well beyond controls.

Weil-McLain highlighted its Eco Hybrid Dual Fuel Hydronic System, pairing an air-to-water heat pump with a boiler to support flexible operation across weather conditions and load profiles. The system was also recently recognized as the Plumbing & Mechanical 2025 Product of the Year, signaling broader industry validation of hybrid hydronics as a long-term solution.

The display underscored a recurring theme throughout the show: hybrid systems allow engineers and contractors to reduce emissions while maintaining performance during peak demand and cold-weather operation without forcing an all-or-nothing shift in fuel source.

Compact electric boilers from PVI Industries illustrate how electrification is increasingly positioned as a supplemental component within hybrid hydronic systems.

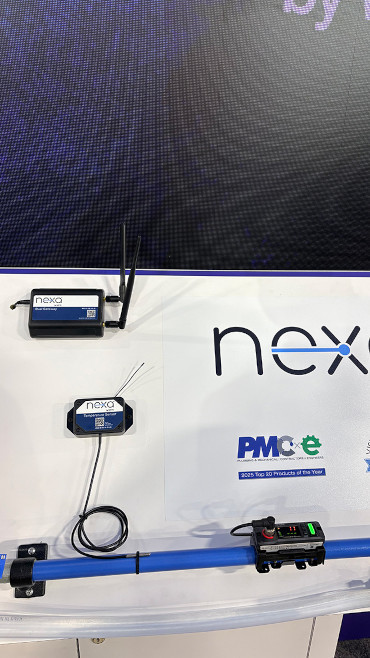

Nexa exhibit

Images courtesy of Natalie Forster

Smaller electric boilers support hybrid strategies

Another trend tied directly into the hybrid conversation was the miniaturization of electric hydronic equipment.

PVI Industries, another Watts brand, showcased its compact electric boilers — including the Durawatt Mini and Bolt Mini — as targeted, space-conscious solutions. Rather than being framed as full system replacements, these smaller electric units were presented as modular components that can support zoning, redundancy, or peak-load assistance within hybrid designs.

The reduced footprint and “Mini” positioning reflect how electrification is increasingly being approached selectively and strategically, particularly in buildings where space and mechanical or electrical infrastructure are constrained.

Smart hydronic controls from tekmar illustrate how hybrid systems are increasingly managed through controls, diverting valves, and intelligent staging rather than single-fuel solutions.

METUS’ compact, packaged hydronic heat pump units on the show floor reflect the industry’s focus on space efficiency and easier placement in residential and light commercial applications.

Webstone’s modular valve kits demonstrate how standardized components can support a wide range of hydronic system configurations while simplifying installation and inventory management.

ACR exhibit

Images courtesy of Natalie Forster

Mechanical room space drives system design

Space efficiency was one of the most consistent design priorities across AHR Expo 2026 exhibits. Pressure boosting systems, pumps, and hydronic assemblies are being presented in vertical, wall-mounted, or in-line configurations aimed at minimizing mechanical room footprint. Franklin Electric highlighted this shift with its Inline SpecPAK pressure boosting system, promoting a zero-footprint configuration paired with scalable performance and integrated controls.

Space efficiency extended well beyond boosting systems. At A. O. Smith, tall, vertical water heating units with integrated controls were displayed to emphasize capacity without expanding floor space. Cutaway presentations highlighted internal coil configurations and component layouts designed to maintain service access despite tighter footprints.

Across the floor, manufacturers clearly recognized that mechanical room square footage is now a premium, and equipment design is evolving accordingly.

Vertical water heating equipment from A. O. Smith emphasizes capacity and service access while minimizing mechanical room footprint.

Hybrid systems for all applications dominated the show floor in 2026.

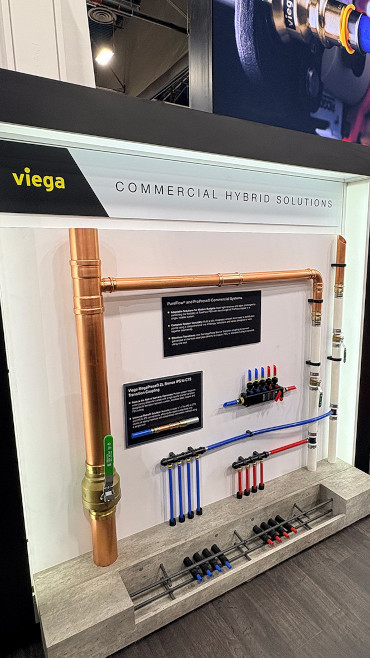

Viega showcased its wide array of hydronic and HVAC solutions, including these commercial hybrid systems.>

Bradford White showed off its new ultra-high efficiency water heaters.

Images courtesy of Natalie Forster

Packaged systems and prefab

Prefabrication and factory assembly are shifting from nice-to-have to a contractor expectation.

At Taco Inc.’s new TridentBoost packaged pressure boosting system was displayed as a factory-assembled solution with integrated pumps and controls. The system reflects a broader push toward pre-engineered assemblies that reduce field labor, streamline commissioning, and improve installation consistency.

This emphasis on packaged solutions mirrors the reality many contractors face: fewer skilled installers, tighter schedules, and increasing system complexity.

Prefabrication was evident across valves, fittings, and boiler platforms. At Legend Valve, the LegendPress portfolio was displayed across carbon steel gas and copper press systems, highlighting standardized connections that support faster installation and repeatable results. Messaging around precision pressing and modular compatibility reinforced how press technology continues to underpin prefab strategies.

Valve kits and fitting assortments from Webstone further emphasized how fewer core components can support a wide range of system configurations; a theme with clear implications for distributor inventory strategies.

Boiler manufacturers also leaned into usability. At U.S. Boiler Co., a cutaway display of its Alta boiler with “ONE Touch” technology showcased factory-installed components and organized internal layouts aimed at simplifying installation and service. The one-touch functionality reinforces the growing focus on usability alongside performance.

Franklin Electric’s Inline SpecPAK pressure boosting system reflects the push toward wall-mounted, zero-footprint solutions designed for tighter mechanical rooms.

Announced at the show, portable pipe threading and oiling tools from Milwaukee Tool support cleaner, more controlled fabrication workflows both in shops and on job sites.

A packaged cooling system from ClimaCool reflects how data center demand is driving prefabricated, factory-assembled thermal management solutions.

AHR Expo 2026 entrance.

Images courtesy of Natalie Forster

Data centers shape hydronics packaging

The data center market continues to expand rapidly, with global capacity expected to nearly double between 2026 and 2030 as cloud computing, AI, and edge workloads accelerate demand. This growth is matched by strong expansion in the data center cooling market, which analysts project will exceed $40 billion worldwide in the next decade, and North American cooling systems alone are expected to surpass $8 billion by 2026. In this context, prefabricated hydronic and thermal management systems are increasingly relevant for facility designers and mechanical contractors. To no surprise, nearly every booth the Plumbing & Mechanical team visited reinforced the growing data center demand.

Large, factory-assembled cooling and hydronic systems, including displays from ClimaCool, highlighted how prefab, modular design is being driven by data center demand. Exposed internal layouts and packaged assemblies emphasized rapid deployment, redundancy, and predictable performance.

As data center construction accelerates, those same design principles are increasingly carrying over into other commercial and industrial hydronic applications.

A grounded evolution for plumbing and hydronics

The plumbing and hydronics story gathered from walking the AHR Expo in 2026 reflects an industry focused on seamless execution while addressing labor constraints, space limitations, infrastructure realities, and tightening project timelines.

Hybrid systems, compact electric components, packaged assemblies, and prefab-ready designs all point to a market prioritizing practicality. For the PHVAC channel, AHR reinforced that hydronics progress is increasingly about how systems are built and delivered, not simply what’s new.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!