Check valves explained: Understanding different types and applications in backflow prevention

Learn about check valve types (swing, ball, diaphragm, dual-plate) and their crucial role in backflow prevention.

Plumbing isn’t rocket science… until it suddenly is. Most people think of it as “water in, water out.” But what isn’t seen—what’s happening behind the walls and under the floors—is way more complicated than that. Pressure shifts. Direction changes. Flow control. If something slips? That’s when the real problems begin.

And here’s the kicker: backflow incidents cause thousands of dollars in damage every year, with the EPA estimating over 10,000 cases of water contamination annually in the U.S. alone.

Now, one of the smallest parts in the system—the check valve—is what keeps everything playing nicely. It’s a quiet workhorse. In this guide, we’re going to keep it real and break it all down:

- What do check valves actually do

- Why do they matter so much (especially for backflow prevention)

- The different types you’ll come across

- And how to pick the right one for your setup—whether that’s a backyard sprinkler system or an industrial pump line

What is a check valve?

A check valve is similar to a one-way door. For example, the valve opens up when fluid wants to pass through the pipe in the appropriate direction. But when it attempts to go in the opposite direction — bam — it slams shut. No electricity. No switch. Just physics and pressure.

Check valves are found in and around a pump system, a sump pit, or cracked open a main line. They’re everywhere. And there’s a reason they’re there: to prevent backflow.

Backflow isn’t just unpleasant—it’s a serious hazard. It occurs when water or other liquids flow in the opposite direction, contaminating clean systems. This could mean sewage entering your drinking water supply or hazardous chemicals reversing into a potable water line.

Here’s what backflow can cause:

- Contamination in your drinking water

- Burnt-out pumps and pressure tanks

- Ruined filters or reverse osmosis systems

- Plumbing fines, failed inspections, or worse

That’s why even the smallest house system—like a sprinkler line that connects to your hose—often needs a check valve. The same goes for massive systems in factories and treatment plants. No one wants water flowing the wrong way.

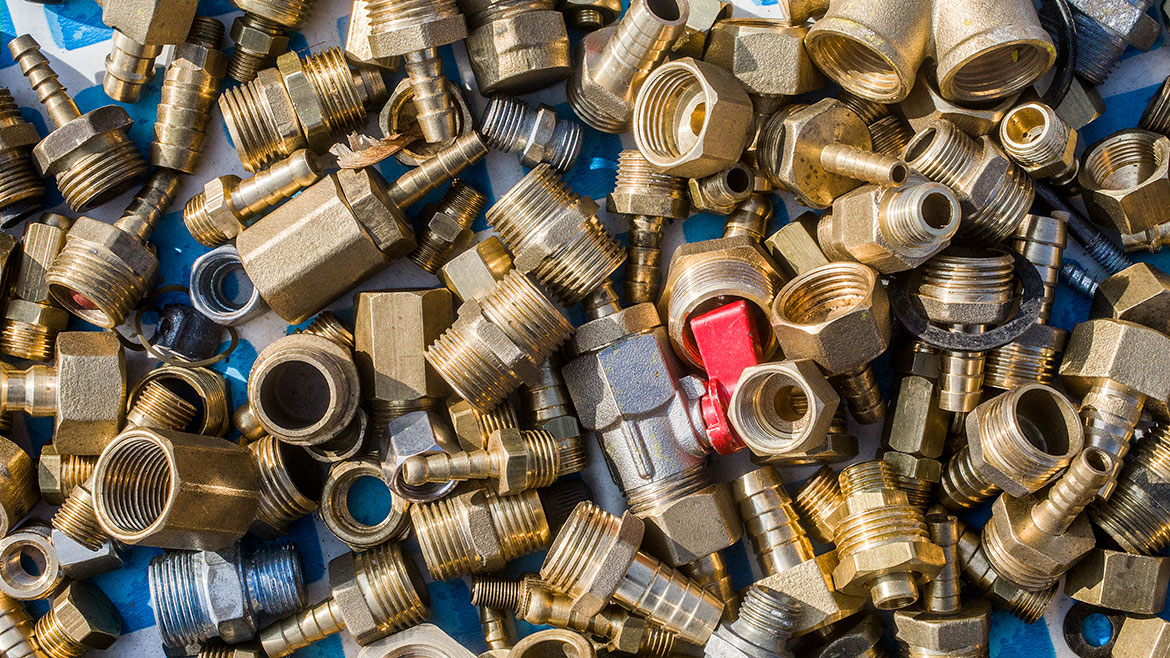

Image source: SlobodanMiljevic / iStock / Getty Images Plus

How do check valves work

Let’s take the mystery out of it. Check valves open when liquid flows forward, and they close when it stops or tries to flow the other way. That’s it.

Now, how they open and close depends on the design. There are two basic ways:

1. Spring-loaded

These are quick to react. A spring holds the valve shut by default. When fluid pushes hard enough in the right direction, the spring compresses and opens the valve. Once pressure drops, the spring snaps it shut again.

Why it matters: These valves are great when you need a tight shutoff, fast reaction time, or you’re dealing with vertical pipe runs, like in a well system or tight basement pump setup. They don’t care about gravity. They just do the job.

2. Gravity-operated (Swing Style)

These rely on a flap or disc that swings open when fluid flows through. If the flow slows down or reverses, gravity pulls the disc back into place.

Why it matters: These work best in horizontal pipe runs. You’ll often find them in large lines, especially in water treatment or irrigation systems. But they’re slower to close and can create something called “water hammer”—that loud clunk you sometimes hear in pipes.

Not all check valves are built the same

So here’s where it gets interesting. Just like you wouldn’t wear steel-toe boots to the beach, you wouldn’t use the same check valve for everything. Different systems, flows, and fluids need different types.

Let’s walk through the most common ones, and when you’d actually use them.

Swing check valves

- What it is: A disc on a hinge swings open and closed as water flows.

- Where it shines: Large pipes, steady horizontal flow.

- Think: Fire sprinkler mains, sewer lines, big irrigation systems.

- Why it might not work: Not good for vertical setups, slow to close. Can bang around and wear out faster in high-pressure systems.

Ball check valves

- What it is: A ball sits inside a chamber and moves with the flow. When fluid moves forward, it lifts. When it stops, gravity or reverse pressure drops the ball to seal.

- Where it shines: Dirty, sludgy, or debris-filled fluid.

- Think: Sump pumps, stormwater lines, wastewater systems.

- Why it matters: Super low-maintenance. Nothing much to jam.

Diaphragm check valves

- What it is: Inside the valve is a soft rubber diaphragm that flexes when water flows forward and flattens back into place when pressure drops or reverses.

- Where it shines: Clean systems with low pressure. These valves don’t clang or bounce. They seal tightly and operate silently.

- Think: Labs, medical facilities, small water treatment setups.

- Watch out for: They don’t like high-pressure environments. If your system pushes hard or flows fast, a diaphragm valve might struggle to keep up.

Dual-plate check valves

- What it is: This one has two spring-loaded plates that open like double doors when flow moves forward, and snap shut fast when flow reverses.

- Where it shines: Big-time systems that move a lot of water—or other fluids—under serious pressure.

- Think: HVAC systems, processing lines, refineries.

- Why people like it: It’s compact and quick. It helps reduce water hammer and works well in tight spaces.

- Downside: It’s more expensive than your standard check valve, and if you’re dealing with really dirty water, those plates can wear down over time.

Why valve material matters

Here’s the part people skip. You’ve got the right valve type, but if it’s the wrong material, the valve can break down quickly. That’s when leaks happen. That’s when systems corrode. That’s when you’re replacing a valve six months after you just installed it.

Let’s make it simple:

- PVC (Polyvinyl Chloride) – Lightweight, doesn’t rust, easy to install. Great for cold water, low pressure, and systems that don’t carry anything corrosive. Think sprinklers, pools, and basic plumbing lines.

- CPVC (Chlorinated PVC) – Same as PVC, but with better heat resistance. If you’re running hot water or dealing with higher temps in your system, this is your move.

- Brass – Strong, long-lasting, and approved for drinking water. If you’re working in residential plumbing, especially for anything connected to the main water line, brass is a solid pick.

- Stainless Steel – The tough guy. Built to withstand pressure, extreme temperatures, and harsh chemicals. You’ll see this in factories, chemical plants, or places that can’t afford corrosion.

Quick tip: Don’t pick the material based on price. Match it to what’s actually flowing through the pipe.

Backflow isn’t just unpleasant—it’s a serious hazard. It occurs when water or other liquids flow in the opposite direction, contaminating clean systems. This could mean sewage entering your drinking water supply or hazardous chemicals reversing into a potable water line.

How to choose the right valve for your setup

This is where a lot of people guess—and guessing gets expensive. Before you buy, take 10 minutes to think through the system you're dealing with. Ask yourself:

1. What's the flow like?

Is it constant? Does it stop and start a lot? If it surges or pulses (like a well pump turning on and off), you'll want a spring check valve to close quickly and stop water hammer.

2. Is your system vertical or horizontal?

Swing valves need gravity to help them close, so they’re not meant for vertical pipes. If your setup is vertical, use a spring-loaded or ball valve.

3. What’s in the pipe?

Is it clean water? Wastewater? Acid? Sediment? That affects both the valve type and the material. You don’t want a brass valve in a line that carries bleach or chemicals—it’ll corrode fast.

4. How much space do you have?

Some valves are long and bulky (like swing valves), while others are more compact (like spring or dual-plate valves). Measure before you buy.

5. Will you need to access it later?

Don’t bury the thing in a wall or seal it under concrete. One day, it’s going to need cleaning or replacement. Make sure you—or someone else—can reach it without tearing everything apart.

Installation tips (How to avoid the usual mistakes)

Check valves are easy to install—but only if you pay attention. Here’s where people mess it up:

1. Installing it backwards.

Every check valve has an arrow showing the direction of flow. It’s not there for decoration. Ignore it, and the valve just becomes an expensive plug.

2. Mounting it in the wrong orientation.

Swing valves don’t work in vertical lines. Spring and ball valves are more flexible, but even they need proper alignment.

3. No access for maintenance.

Out of sight, out of mind—until it fails. If you need to cut open drywall or dig up concrete to check the valve, you’ve already lost.

4. Wrong size.

Too small and you’ll get reduced flow or pressure loss. Too big, and the valve might not close fully, leading to leaks or fluttering.

Pro tip: When in doubt, size your valve based on flow rate, not just pipe diameter. And talk to someone who’s worked with the setup you’re building. Experience saves money.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!