Lowell Manalo: The importance of group collaboration in plumbing systems’ design

Designimus, Defendimus

Vladimir Kononok/iStock/Getty Images Plus via Getty Images

An individual person’s idea is good — the team’s idea is better!

Plumbing systems engineering and design are better with group collaboration. I was in the U.S. Navy, and the Seabee’s motto is, "Construimus, Batuimus," which means "We Build, We Fight." We are trained to fight and defend what we build.

Keeping true to my background and passion, I used this motto as a baseline for creating my own. Applying it to the plumbing engineering design industry, "Designimus, Defendimus," which means "We design, we defend." We design, and, at times, defend our designs. By using individual experience, expertise and code knowledge as a collective resource, we put in place a powerful tool in the defense of our designs.

Another way to elevate your design is by using your previous experience in life. These experiences can come from old work experiences, hobbies and other interests. Find a way to incorporate this into your design. While standards and codes define minimum requirements, if you couple these with your passion, knowledge from previous work and personal experience, you can take your designs further.

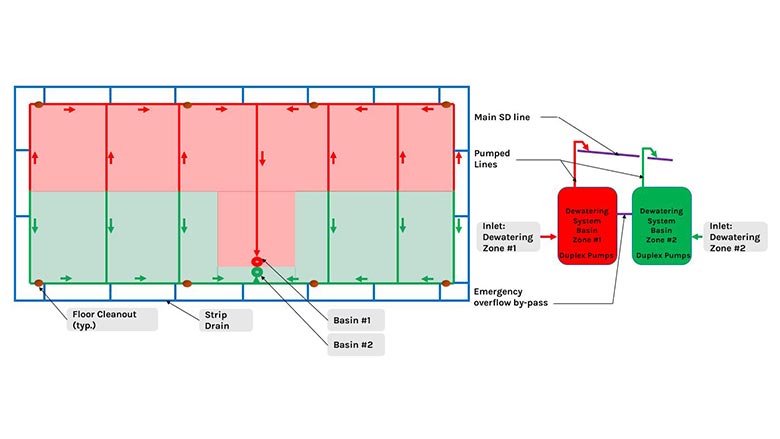

For example, I was part of the design team for a lab building in California a few years ago. Due to site limitations, a basement was needed to support all the program spaces. Unfortunately, the same site has a high-water table which requires a dewatering system. Knowing the importance of the product stored in the basement, I got excited and asked, "What can I do better? How can we improve this for the client and community it serves?" At that point a drum starts beating in my head, driving my passion for design excellence. Using my background in the U.S. Navy, the concept for the dewatering system used techniques in designing compartmentalization for a naval ship for flood mitigation. The dewatering system has two zones (refer to Figure 1). The pipe routing and cleanouts are strategically placed with the ability to add sensors to identify where the water is coming from. Each zone is then connected to a basin with duplex sump pumps. The interconnection provides for continuous operation even if one sump is being serviced.

Figure 1: Water dewatering system. Image courtesy of SmithGroup

This concept is then extended to the rest of the team to provide feedback. It doesn’t matter if you are new to the industry, an intern or a well-seasoned engineer or designer — you will have an equal "seat at the table." As a team, we threw multiple darts at the idea, challenging the concept's validity, feasibility and constructability. This process is what we call the "stress test." This also includes soliciting feedback and review from other design disciplines, manufacturers and contractors. A good idea from one individual becomes excellent when combined with your peers’ views and opinions. In the process of explaining concepts to others, preconceived assumptions may be challenged leading to more discovery.

One challenge that plumbing engineers and designers often face is the limited time and/or opportunity to present their ideas to clients. We need better storytellers as it relates to drawings, documentation and presentations. Know your audience! While most people do not understand all the nuances of plumbing system design, it is possible to describe systems in such a way that the regular person understands the reasons why the systems operate or are configured in such a way. As we don’t usually get many opportunities to present to clients, when you do, make every second count!

Project pursuits often limit our narratives and ability to explain the systems due to space constraints. Over my 20-plus years in our industry, I observed that plumbing presents less information than other disciplines. Why is that, and how can we convey more information with limited space?

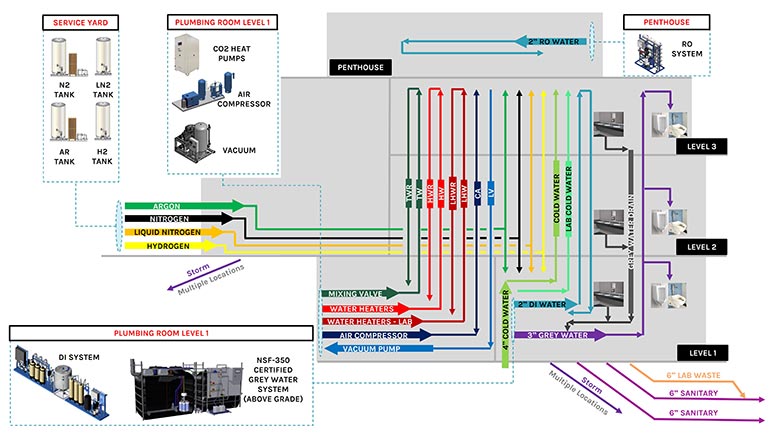

To continue elevating the plumbing design community, we must speak up and be our champions. Recently, we were pursuing a high-profile laboratory project. The same question came to my mind — "What can we do better" to help the team?

Knowing the limitations of our narratives and only being allowed to have one sketch per discipline, we knew we needed to make this count. We started creating multiple iterations of a sketch and then presented it to the team for comments and collaboration. The result was a product that clearly conveyed both the systems and distribution planned for the facility. And the cherry on top — we won the project!

Figure 2: Plumbing system diagram. Image courtesy of SmithGroup

As I pass by buildings that we designed, it brings a smile to my face and motivates me more knowing that long after I am gone, these buildings will continue to serve people in our community. A significant part of what made this happen is the team collaboration — "Designamus, Defendimus."

Happy Fourth, everyone!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!