Water Wisdom: Are you prepared for TDS Creep?

Regular maintenance is required for water treatment systems.

Installing a reverse osmosis (RO) system for a homeowner is not a once and done event. Just like any other kind of water treatment technology, RO systems require regular maintenance. This includes periodically replacing the unit’s pre-filters, postfilters and membrane modules. In addition, TDS creep might be a challenge.

What is reverse osmosis?

RO systems force water, under pressure, into a module that contains a semipermeable membrane. The membrane allows water molecules to pass through while holding back (rejecting) dissolved salts and some organic substances. A typical RO system has a pre-filter designed to capture larger particles, chlorine and other substances; a semipermeable membrane that captures more contaminants; an activated carbon filter that removes residual taste, odor and some organic contaminants; and a storage tank to hold the treated water for use.

Whole-house (point-of-entry) RO systems exist, but RO systems are more commonly installed at the point-of-use, such as on a countertop or under a sink. They are great for treating water for cooking and drinking, but they don’t usually produce large amounts of treated water — about 3 to 10 gallons a day. As a result, people often choose to install RO-treated faucets in the most popular areas of the home such as kitchens and bathrooms, as opposed to installing it for every drinking tap.

RO systems can be used to treat a variety of water challenges. For instance, one of the best ways to reduce chromium-6 is through a reverse osmosis system. RO devices are also effective in reducing nitrates, arsenic, cadmium and several perfluorinated compounds (PFCs) in drinking water.

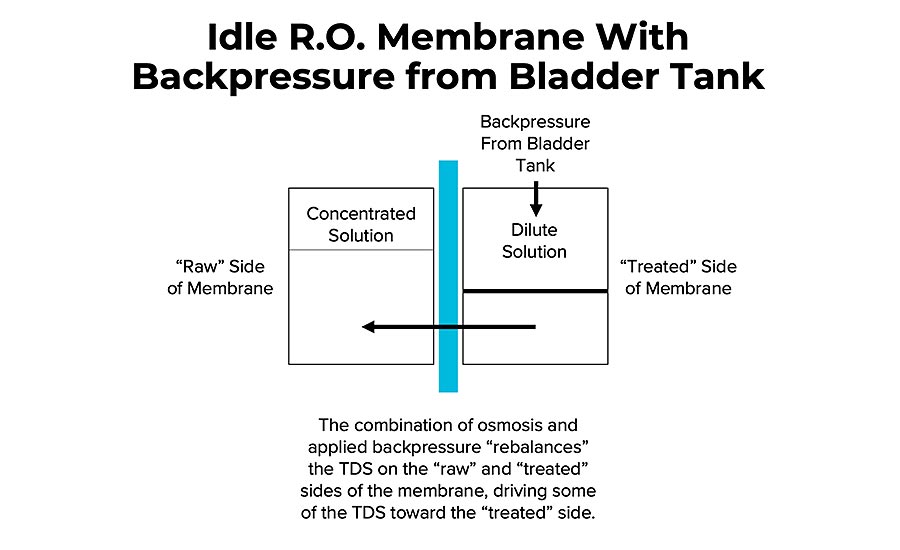

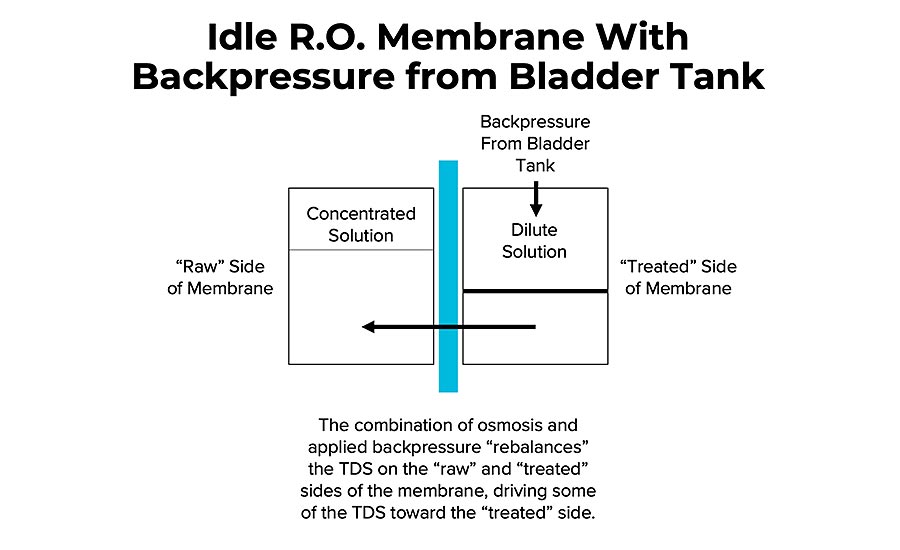

One of the problems that can occur with RO systems is called TDS creep. TDS stands for total dissolved solids or total dissolved substances in the water, primarily inorganic salts and minerals. When an RO system sits idle and there is no active pressure being applied to the raw water side of the membrane, TDS can creep into the treated side of the membrane. This happens most often when the system is not sufficiently flushed when first turned on. A dramatic reduction in TDS can typically be seen after letting the faucet run for 10-15 seconds.

According to Justin Mest, head of science and technology for Master Water Conditioning Corp. in Pottstown, Pennsylvania, you typically don’t want to feed RO-treated water through any metals susceptible to corrosion without proper post-treatment. Taste is also an issue. “Most people don’t like the taste of very low TDS water,” Mest says. “That’s why you often see re-mineralizing filters on a lot of under-sink RO systems because the water tastes bland.”

But the issue of TDS can become a much bigger challenge for commercial or industrial water treatment applications.

“A difference, say, of 1 to 2 ppm TDS can be the difference of a manufacturing process working and a manufacturing process failing,” Mest said during an interview about his on-demand education session for the Water Quality Association’s July Convention. He added that an automated flush system, which helps ensure delivery of fresh membrane-processed water, can be essential.

All of this factors into the size of an RO system being installed. An RO device that is oversized for the amount of water being used means the membrane is less active, increasing the likelihood of TDS creep.

“You can very easily oversize an RO system, and you’re going to make lots of water, but the water quality is probably going to be garbage,” Mest says.

The Water Quality Association trains industry professionals on the application of RO systems. It also encourages both professionals and consumers to be aware of pre-treatment and post-treatment requirements for optimum performance of RO systems, and to choose efficient system designs and configurations. (Efficiency and recovery ratings can be evaluated under NSF/ANSI Standard 58).

To read more about RO treatment concerns, please visit the technical pages on www.wqa.org.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!