PM Profile: Taco’s Mark Chaffee

The continued evolution of pumps. Taco’s Mark Chaffee talks energy efficiency, new government regulations and self-sensing technology.

MARK CHAFFEE // VP, GOVERNMENTAL RELATIONS, TACO COMFORT SOLUTIONS.

Taco’s Chaffee says one key new trend is the proliferation of new, high-efficiency products. “Pumps that are entirely new with greater capabilities and integrated controls, or pumps that have been redesigned by manufacturers with maximum efficiency as the key goal,” he says.

One key change in the pumps arena is the introduction of new DOE pump energy rating labels.

Plumbing & Mechanical recently had the chance to catch up with industry veteran Mark Chaffee, the vice president of governmental relations and sustainability at Cranston, Rhode Island-based Taco Comfort Solutions. Here, Chaffee sheds insight on a variety of topics that are impacting the commercial/industrial pumps industry.

PM: What trends are you seeing now with pumps, particularly ones being used in commercial/industrial settings?

MC: The big trend is the proliferation of new, high-efficiency products — pumps that are entirely new with greater capabilities and integrated controls, or pumps that have been redesigned by manufacturers with maximum efficiency as the key goal.

Over the past year, demand for improved system and energy efficiency has continued to move apace throughout the industry, especially for large commercial HVAC system pumps. The ECM motor, now, for instance, available up to 30 HP from Taco, has added to the overall efficiency. But in combination with self-sensing controls, it’s a game-changer in the pump market.

These controls are evolving rapidly and are having a bigger impact on system operation and efficiency while simplifying commissioning. Specifiers and building owners alike now have the advantage of pumps to self-regulate based on the actual head and flow of the installation instead of what was estimated on the plans.

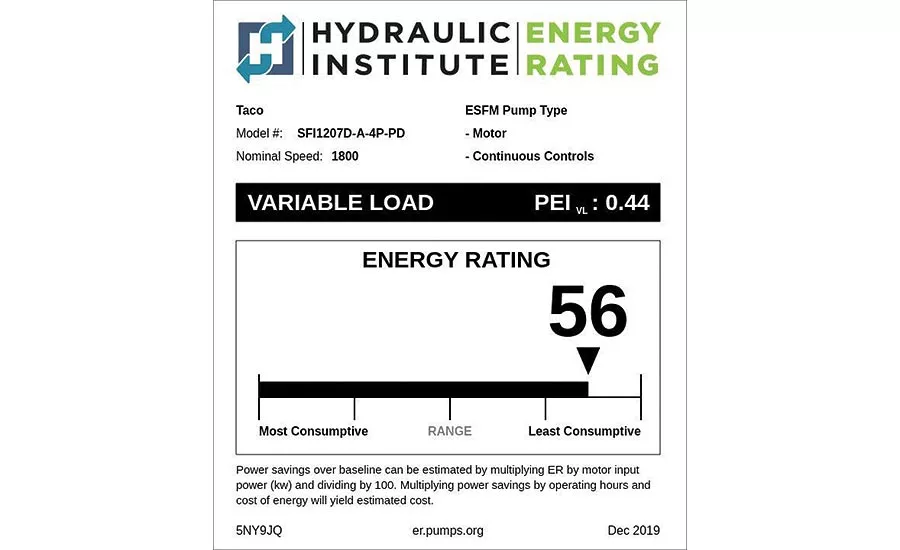

It’s also important to note that the new commercial pump energy rating labeling (see below) more easily allows utility companies to offer incentives for the installation of the high-efficient pumps.

PM: Is there anything of concern to you in the pumps realm or things to keep an eye on?

MC: Now that the Department of Energy’s new regulations are in place (as of Jan. 27), there are important considerations that pump specifiers must be aware of. Familiar pump models probably have been enhanced to achieve higher efficiencies, changing their performance ranges and capabilities as well.

This may mean engineers, designers and specifiers must reselect product on plans that are currently in submittal stage because once released they might not be available anymore or their performance and selected efficiency points have changed. Now’s the time to review standard specifications and guidelines, most that were probably written several years ago, to include the need to be DOE compliant, have an energy rating and take advantage of the latest technology and efficiency gains.

PM: What is the next big thing with pumps in your opinion? Where is this space headed?

MC: An important change is the new DOE pump energy rating (ER) labels, how to use them and why. The labels are designed to clearly indicate power savings obtained from pump system upgrades and changes. Manufacturers use the ER label to differentiate products by power consumption. Utilities will use the ER label to determine Kw savings for incentive programs and rebates. Two power savings calculations are presented. One is for variable-load (PEIVL) and another is for constant-load (PEICL) pumps.

The labels provide a wealth of useful information and data. Specifiers and designers can use them to compare different pump models, even across brands. They’ve also become great for engineers to substantiate upgrades or quickly evaluate the savings associated with the adding of variable speed drives. One can even get a quick estimate of actual dollar savings by choosing a more efficient pump.

The labels also present opportunities for more intelligent conversation with end-users about how improved, more energy efficient, high-performance pumps help them improve a building or facility’s bottom line — not to mention they will be the basis of most utility incentive programs moving forward. With more than $9 billion of incentives distributed every year to encourage the purchase of energy efficient products, it’s going to be nice to see a chunk of that money flowing to the clean water pump market!

In addition, self-sensing technology makes the installation of pumps and drives much easier. Self-sensing pump and drive packages are characterized to that specific pump, so they automatically adjust to the optimum system operation point. Capabilities such as these will move the market because of the pump’s inherent intelligence, use of less energy to achieve optimal performance and reduction of installation and commissioning costs.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!