Radiant Comfort Report | May 2020

REHAU radiant heating and cooling systems contribute to increased comfort in student housing projects

The hydronic system maintains the spaces at even, comfortable temperatures while using less energy than traditional forced-air systems.

Fort Lewis College West Hall in Durango, Colorado, converted to a district energy strategy with three high-efficiency boilers in one location to reduce mechanical equipment, save energy and increase comfort.

University of Chicago Campus North Residential Commons where student living quarters use REHAU in-slab hydronic radiant heating and cooling to improve energy efficiency and enhance comfort for the students.

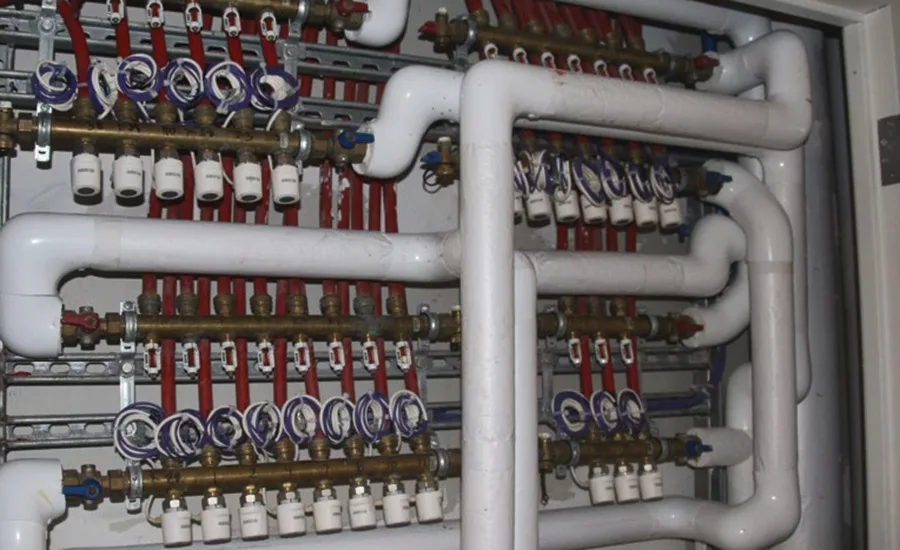

Tight mechanical spaces in hallways prevent unneeded room entries.

In addition to dorm rooms, some common areas of the residence hall complex, including this multistory space, are heated and cooled with REHAU radiant technology.

REHAU INSULPEX pre-insulated PEXa piping being installed throughout Fort Lewis College to transfer energy efficiently between a centralized boiler room and several residence halls.

When I was in college, I learned some of the worst practices for thermal comfort in the residence hall. I was one of the lucky students, because I was in a newer dorm building with personal control of my HVAC system. By control, I mean I had infinite choices for an in-unit air handler. I could pick system heat, cool or off. I could also choose a fan speed of low or high. The real fine-tuning option was the operable window. You could open that thing from 0-100%, regardless of any other equipment settings.

As an energy-conscious son of a radiant heating installer, I would turn off the HVAC system when I opened my windows. However, I was one of the very few students adhering to this policy. The other students on my floor had all sorts of ways of navigating around the comfort options we were given. Even in the spaces where students were “locked out” with the clear plastic lock boxes you can put over a thermostat, students weren’t taking “no” for an answer. In the winter, they would put one of those small cooler reusable ice packs on top of the plastic protective box to make the thermostat think the room was colder than it actually was. The summer equivalent to this trick is plugging your phone into a wall charger and leaving it on top of the box so the warm device keeps the thermostat in cooling mode for a lower setpoint.

Thermal comfort wasn’t the only reason windows were so frequently used to modulate indoor environmental conditions. Sometimes, the other rooms on your floor stunk. Some kid on my floor junior year had a special knack for burning popcorn in the community microwave down the hall every other day. Because of this, an operable window was a great luxury. You could actually get a full air change into your room with the window, instead of recirculating the popcorn ash all day. Some of the kids on my floor remembered to close the windows after the unpleasant smell cleared up; some would leave for the weekend, or spring break, without closing their windows.

How can you build a better control system for students in a dorm? What is the best balance between personal control and efficient building operation? The answer will be site-specific, but you might not be as limited as you think. The University of Chicago came up with a great plan. They set out to build a residence hall with radiant heating, radiant cooling and operable windows in each unit. (Reader spits out their coffee in shock.) In a humid place like Chicago, operable windows and radiant cooling are a recipe for dewpoint disaster, right?

Achieving real-life thermal comfort with high efficiency

With its North Residential Commons building, the University of Chicago built an exemplary residence hall that balances energy efficiency and comfort. The goal was to create a modern structure that would bridge the academic community with the surrounding neighborhood of Hyde Park.

Kevin Rodgers, the university’s campus energy manager, worked with energy specialists at the National Renewable Energy Laboratory to set an aggressive energy-saving target for the new 400,000-square-foot structure. For implementation, in coordination with Studio Gang Architects, dbHMS, Mortenson Construction and Mechanical Inc., the university targeted an annual energy usage intensity (EUI) of 56.6 kBtu/ft2, which is impressive for a building with student housing and dining spaces. EUI is defined as the total amount of energy used by a building per year divided by its total gross floor area.

Compared to the average residence hall usage in Chicago, this EUI represents a 41% reduction, eliminating 1,920 metric tons of CO2 emissions per year. Rodgers indicates that the average university residence hall building in Chicago had an EUI of 96.6 kBtu/ft2 per year in 2016 based on real data provided by five area universities.

By circulating heated or chilled water through 5/8-inch PEXa pipe installed in the ceilings on each floor, the hydronic system maintains the spaces at even, comfortable temperatures while using less energy than traditional forced-air systems. The energy efficiency goals are important, as long as students are comfortable in the spaces. The extended team involved with this project kept this in the forefront of the design.

So how did they solve the challenge of operable windows? A contact sensor was added to the windows in each room. If a window opens, the circuit actuator for that area closes. Students can open their windows, even in a warm, humid Chicago summer. However, when the windows are open, they can’t also continue to radiantly cool that space. Students can choose one or the other, open window or heating and cooling. This simple control consideration allows the students to vent out that inevitable burnt popcorn smell, preserves the ability to have a comfortable thermal environment and doesn’t completely throw the ambitious energy efficiency targets out the window. This is a win/win/win, in my book.

Mitigating mechanical noise with district energy strategy

Outside of the thermal comfort attributes of a dorm, what are other ways to improve the living conditions for students? Equipment noise bothers my sensitive ears. My wife doesn’t even notice this stuff, but I hear equipment short-cycles as if they were push updates to my phone. I’ve lived in a couple of apartments where an open window is nice, from a thermal comfort standpoint on certain days, but the sound of the condenser or chiller outside is so loud, that I prefer to shut the window to hear myself think.

On a college campus, district energy systems can promote tranquility, not to mention improved aesthetics. Fort Lewis College in Durango, Colorado, made the switch from individual boilers in buildings to a central plant with cascading boilers. They distribute this energy to individual buildings with pre-insulated PEX pipe. This way they get the benefit of water-based energy distribution, while also distancing students from the energy source.

District energy isn’t for every project. College campuses are a particularly good application, because occupancy loads are generally high, buildings are usually clustered together and one entity is paying the utility bill for all of the buildings.

As a resident of a college campus with a district energy system, here is what you would or wouldn’t notice while studying. You would not see a row of air conditioners outside windows, like a row of parked cars. You would not hear fan noise of a blower cycling on and off, right behind your wall. As an example, for a total of a 10 million Btu load, instead of seeing 10 different 6-inch boiler vents sticking out of 10 different buildings, you might see two 14-inch vents coming out of the energy plant. Additionally, the maintenance crew might not need to get into your actual unit or space to service equipment. In a radiant district energy system, the only moving mechanical parts in a building may be a thermal actuator in a manifold cabinet, hidden out of site.

In a way, we could build our college campuses like trains. One locomotive does all the work and pulls the cars silently behind. One central energy plant building can act as the locomotive, specializing in energy efficiency, allowing all the other buildings to specialize in human comfort, with minimal mechanical intrusions.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!