Using technology to boost the power of parallel pumping

Technologically advanced controllers and variable speed drives help achieve maximum efficiency.

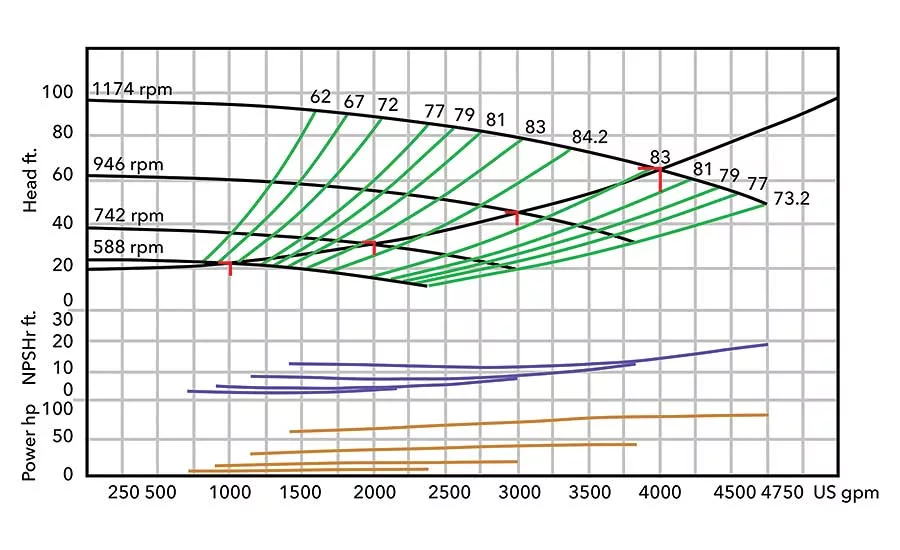

Figure A

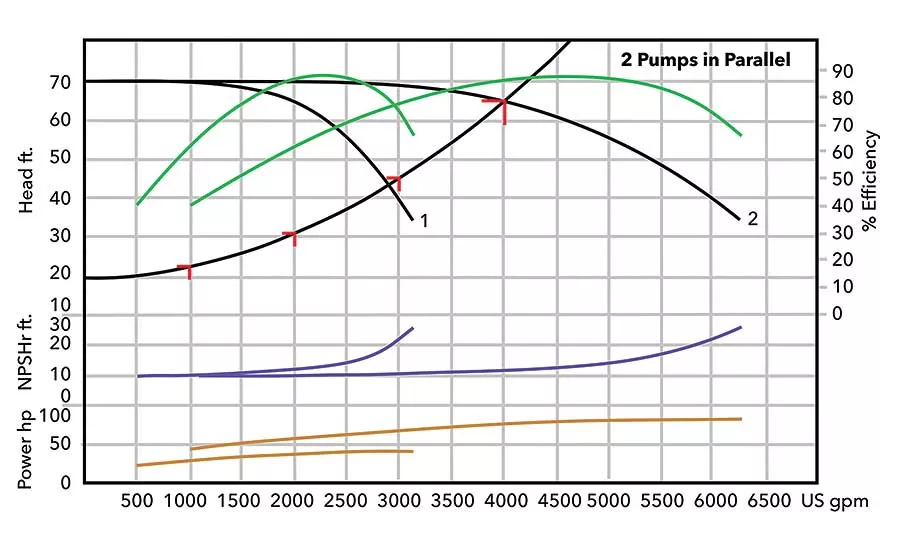

Figure B

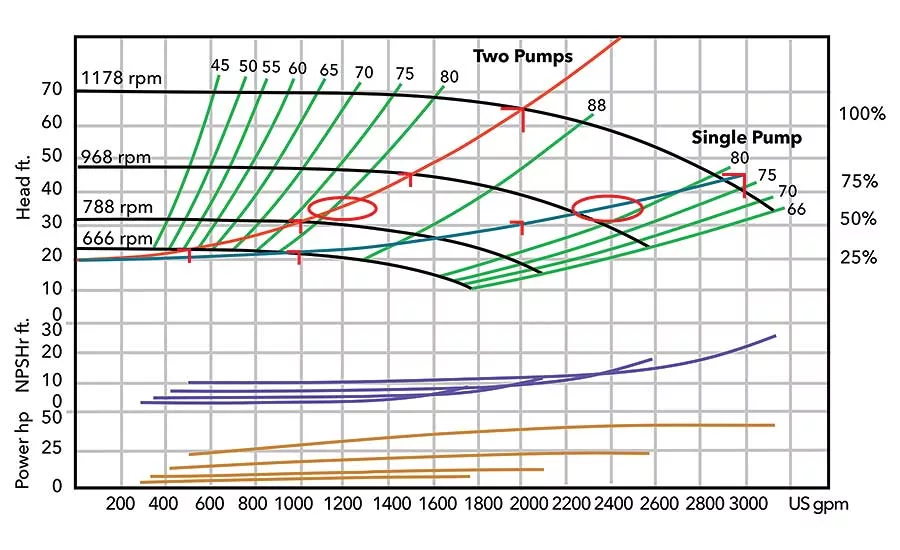

Figure C

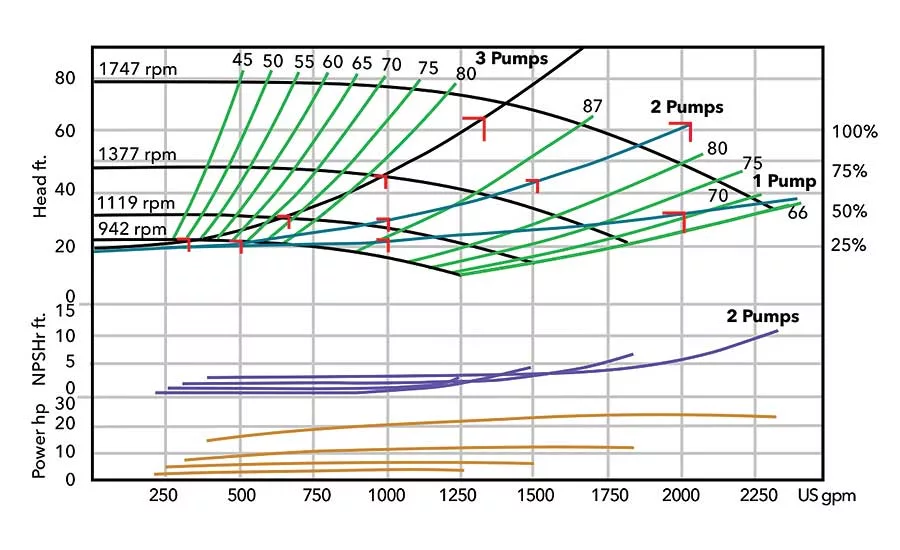

Figure D

Figure E

Parallel pumping is an established application for improving efficiency in pumping systems with higher flows and variable load. Now, with the rise of sensorless pump control technology, parallel pumping systems can be further optimized for improved energy savings where remote sensors are not possible or practical.

In a parallel pumping system, the controller dynamically makes decisions based on what the current flow and head requirements show. While sensorless control technology enables variable speed adjustment, traditional staging based on fully loading each pump will not optimize the system. A smart controller combined with sensorless pumps can add high efficiency, backup capacity and potential savings on space and initial investment.

Sensorless pump control technology relies on pump-specific algorithms, which can accurately predict where a pump operates on its curve. Using speed, torque and power data to know where the pump operates on the curve, sensorelss pump controllers can be set up to take action based on those factors.

In an environment where partial loading is the norm, optimizing system performance isn’t as simple as optimizing pump performance at a single duty point. The entire profile of the pump’s efficiency at varying flows and speeds must be considered. In a parallel pumping environment, this makes selection and staging strategies even more complex. Technology helps arrive at these solutions more easily, and parallel pump controllers with the best efficiency staging capability pay dividends.

Selecting a pump for parallel operation using the same methods as choosing a single pump involves cutting the flow in half or a third and picking the most efficient option. When flow gets past 120% of Best Efficiency Point (BEP), it’s time to stage the next pump. However, that process doesn’t leverage technology, and though the system will provide required head and flow, it likely won’t be at optimal efficiency.

OPTIMAL EFFICIENCY

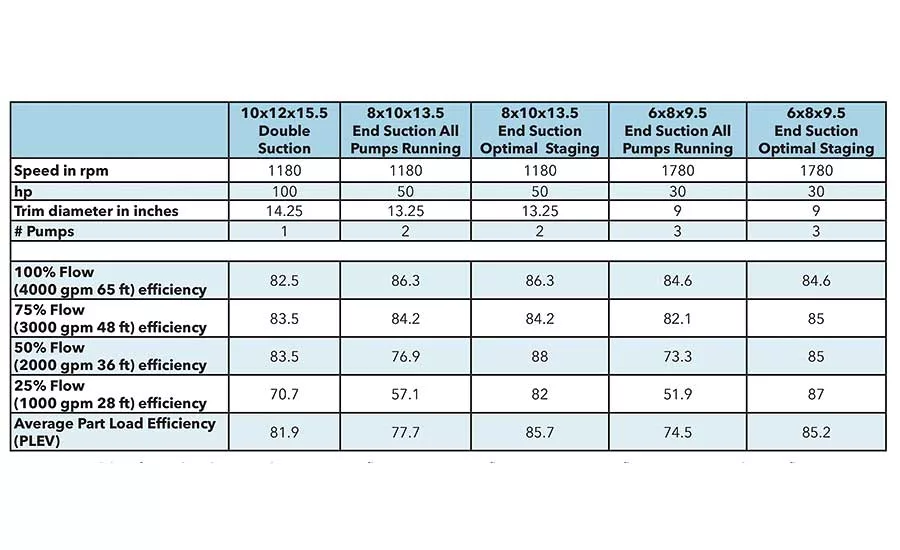

How can pump staging be truly optimized for efficiency? When assessing different staging scenarios and comparing and contrasting the weighted part load efficiency values (PLEV), the challenges and solutions of designing parallel pumping systems become clear.

In the first scenario, the full load requirement is 4,000 gpm at 65 feet of head with a control head requirement of 19.5 feet. These design parameters should be carefully considered, as they dictate the system curve driving the selection decisions.

With such a large pump, the selection would likely be a double suction pump. In Figure A, the curve depicts an efficient solution, especially at full load. There is some tapering at 50% and 25% of load, yielding a weighted part load efficiency value (PLEV) of 81.6%. This is a 10 x 12 x 15.5 pump with a 100 hp 6-pole motor, a large investment and footprint, but one that provides zero backup capacity.

The next option provides backup capacity and even greater PLEV. Figure B shows two end suction pumps in parallel — 8 x 10 x 13.5-inch pumps with 50 hp motors. This constant speed graph demonstrates efficiencies higher than 86% for portions of this curve, meaning there will only be improvements over the curves when variable speed is introduced into the equation. Overall, the system curve crosses all of the test speed curves and demonstrates acceptable efficiencies.

Figure C reflects individual pump efficiency improvements created by variable speed. Dividing the flow between both pumps at full load, efficiency is 86.3% — even higher than the double suction pump in Figure A.

If both pumps continue to run at partial loads, the weighted efficiency is 77%, below the double suction performance. As demand decreases, the second pump must be destaged. As system requirements drop below 2,400 gpm, the two-pump efficiency is actually dropping below 80%, while the single-pump efficiency climbs to 88% as demand drops to 1,400 gpm.

Based on the system curve for this pump, it appears the best staging/destaging occurs around 10% past BEP. With two parallel pumps, one pump can drop off and the system will still operate at 75% capacity.

Figure D demonstrates coverage up to 50% of load with one pump — if system losses haven’t been underestimated. With two pumps, nearly 90% of load is covered. In fact, if the requirement was to meet full duty with two pumps, motors and drives could be upsized to 40 hp and the pumps oversped to almost the same efficiency as the pumps in Figure D, just short of 60 feet at 2,000 gpm per pump. Based on this pump’s efficiency profile, optimal system efficiency will be achieved by running two pumps from 3,600 gpm all the way down to just over 100 gpm or the 25% partial load point.

The initial investment savings on three 30 hp 4-pole motors versus a 100 hp 6-pole motor is 40%. The initial investment savings on three 6-inch pumps versus the single 10-inch pump is roughly 25%.

Figure E shows efficiency benefits that can be achieved by determining the optimal staging point for each parallel pumping solution. It’s important to evaluate the system curve and pump efficiency curves to optimize staging.

In these scenarios, optimal staging in a parallel pumping solution can save 3% on energy costs versus the double suction solution while increasing backup capacity and potentially eliminating system downtime required for maintenance. But if pumps aren’t staged properly, the system could operate 3% less efficiently than the single-pump solution, resulting in more than $1,000 in increased energy costs per year depending on operating conditions and utility rates.

It should also be understood that in a diverse system, there’s a control area rather than a simple control curve. The more diversity in the system, the larger this area. Those are cases where remote sensing combined with intelligent staging will provide the greatest benefits.

The staging points are based on calculated system losses versus calculated motor power requirements. In these examples, the system is modeled using a system curve. In actual application, this curve will need to be reviewed following commission.

It should also be understood that in a diverse system, there’s a control area rather than a simple control curve. The more diversity in the system, the larger this area will be. Those are cases where remote sensing combined with intelligent staging will provide the greatest benefits.

Staging solutions for best efficiency can be a complicated endeavor, but with the aid of a sensorless controller equipped with built-in best efficiency staging, calculations happen dynamically, automatically ensuring the system can indeed deliver these theoretical efficiencies.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!