The Glitch and Fix: Mixed mode

The Glitch:

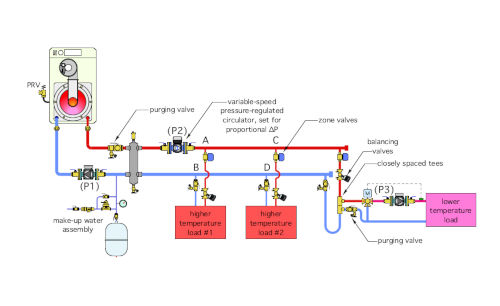

I recently had an inquiry from a designer who needed to combine some high temperature loads with low temperature loads. The latter would be supplied through a 3-way motorized mixing valve. Whenever a mixing valve is used, there must be a circulator between the mixing valve and the low temperature heat emitters. Wanting to hydraulically separate this circulator from the main system circulator, the designer proposed a piping topology very similar to that shown in Figure 1.

The Fix:

Although the closely-spaced tees at points E and F in Figure 1 will provide hydraulic separation between circulators (P2) and (P3), the overall piping arrangement is going to create some undesirable conditions.

The piping on the right side of the hydraulic separator is neither a “2-pipe” system, nor a primary/secondary system. Trying to morph these two piping topologies together is not a good idea.

The maximum differential pressure available to drive flow through the higher temperature load No. 1 will be the pressure differential developed between points A and B due to the head loss around the “loop” serving the closely-spaced tees.

Likewise, the maximum pressure differential available to drive flow through the higher temperature load No. 2 will be that caused by the head loss between points C and D. These pressure differentials may or may not be able to create the intended flow rates through the higher temperature loads.

If the piping path around the “loop” is short, there won’t be much differential pressure. Furthermore, these pressure differentials will also change depending on which of the two high temperature loads is active. It’s not a stable situation.

A more stable situation can be created by eliminating the “loop” portion of the piping, and creating a “crossover” for the lower temperature load, as shown in Figure 2.

The overall piping topology is now a “2-pipe” header system. All three loads connect across the headers. This is no more “primary loop.” All three load branches have a balancing valve to properly proportion flow rate between them.

Circulator (P2) has been converted to a variable-speed pressure-regulated circulator operating in proportional differential pressure mode. This mode will keep the differential pressure across each branch relatively stable regardless of which branches are operating. It will also significantly reduce the pumping energy required by the system.

The closely-spaced tees in the crossover for the low temperature load provide hydraulic separation between circulators (P2) and (P3).

Other glitches that have been corrected:

- Adding a pressure relief valve to the boiler.

- Adding a purging valve to the boiler circuit.

- Adding a make-up water system and expansion tank.

- Showing the purging valve on high temperature load #1 in the correct orientation.

- Adding a purging valve downstream of closely-spaced tees for low temperature load.

Download The Glitch and Fix: February 2020 in pdf form.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!