Installation guidelines for wet underfloor heating

This radiant form of heating draws cold air across the floor, heats it, then moves it up toward the ceiling.

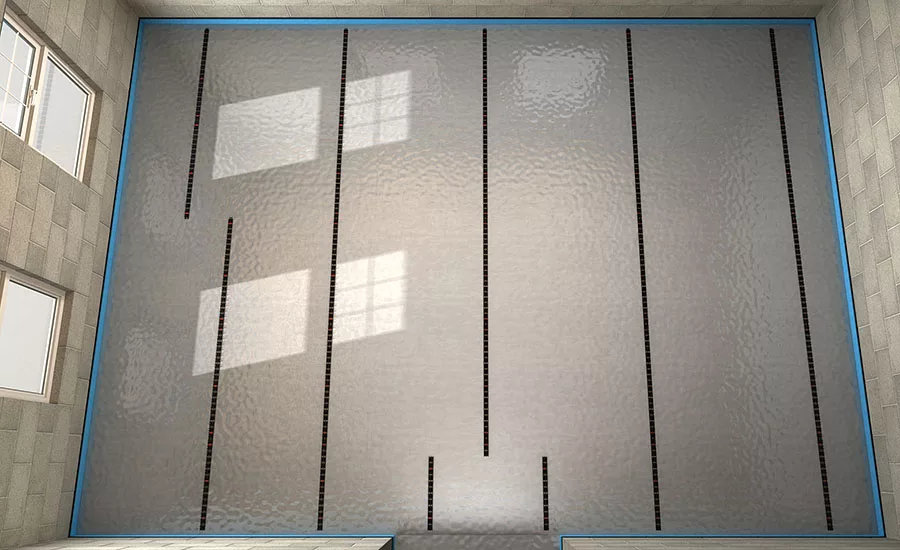

When installing underfloor heating, be sure to refer to the design plan drawings before beginning. All photos courtesy of Ambiente Underfloor Heating Systems UK

For screeded floors, lay the damp-proof membrane over entire floor area, overlapping at least 150mm up walls and where damp-proof membrane sheets meet. All photos courtesy of Ambiente Underfloor Heating Systems UK

Use pipe clips to secure the tail pipework as it crosses the batten/joist. All photos courtesy of Ambiente Underfloor Heating Systems UK

When laying the pipe out, navigate the most efficient route between the manifold and the zone. All photos courtesy of Ambiente Underfloor Heating Systems UK

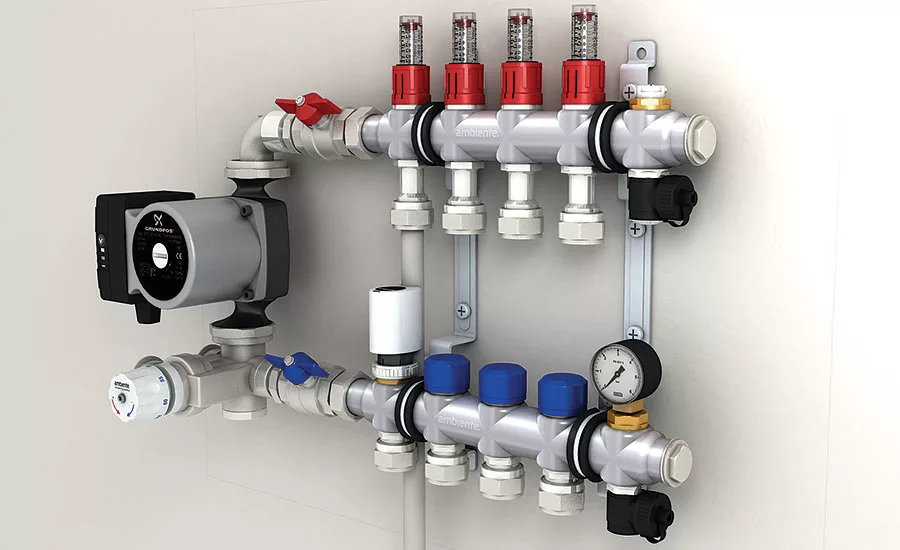

Once all loops are installed and connected to the radiant manifold, the system should be pressure-tested. All photos courtesy of Ambiente Underfloor Heating Systems UK

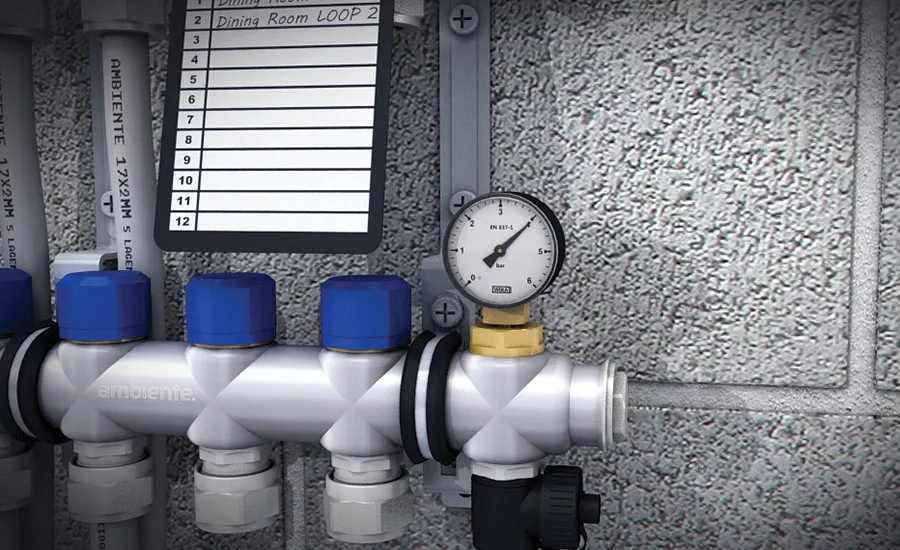

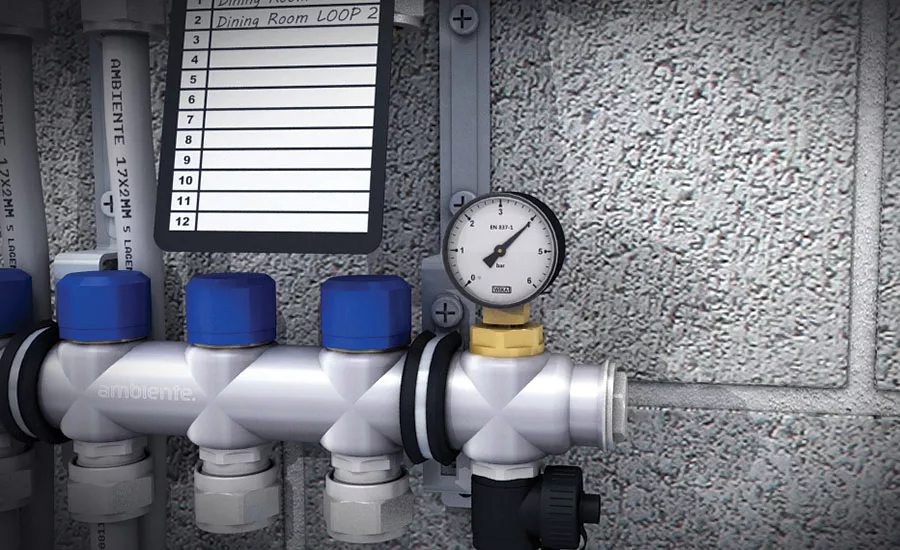

Labeling system loops help make the system easy to trace and troubleshoot. All photos courtesy of Ambiente Underfloor Heating Systems UK

Individual cliprail clips can be used to hold the pipe to the insulation in between the cliprail and on tight bends. All photos courtesy of Ambiente Underfloor Heating Systems UK

Wet (or hydronic) underfloor heating works by circulating warm water through a series of continuous loops that are fitted underneath the floor. This creates a large radiant surface that heats a room from the floor upwards.

This radiant form of heating draws cold air across the floor, heats it, then moves it up toward the ceiling. It is much more comfortable than the convective heat provided by radiators.

The following are general guidelines for installation of wet underfloor heating systems, depending on floor construction.

Joisted floors and most timber floors with joists or battens

For joisted floors and most timber floors with joists or battens, follow these installation guidelines:

-

Refer to the design plan drawings. Prepare to lay the floor in accordance with the layout described.

-

Lay the insulation between battens/joists followed by the grooved diffuser plate. Check the system plans for the number and length of each loop required.

-

Starting on the left side of the manifold, connect to the manifold flow bar.

-

Make a note of which zone the loop serves on the manifold tag supplied.

-

Lay the pipe out, navigating the most efficient route between the manifold and the zone. Pipes will need to be notched into the batten/joist when they loop from one joist void to another

-

Secure aluminum diffuser plate to the batten/joist. Lay pipe into the pre-grooved aluminum diffuser plates, as per the system designs.

-

Use pipe clips to secure the tail pipework as it crosses the batten/joist.

-

Complete the loop. Follow the same route back to the manifold and connect to the return bar (bottom bar with blue caps), making a clear note of the actual loop length installed on the manifold tag.

-

Follow the same procedure for all loops until the area is evenly covered with pipe, following your pipe layout design.

-

Test. Once all loops are installed and connected to the manifold, pressure-test the system.

-

Lay final floor finish after the system has been successfully pressure-tested.

Screeded floor build-up

For screeded floors, follow these installation guidelines:

-

Set up the pipe decoiler and all necessary tools. Make sure the working area is clear and clean.

-

Lay the damp-proof membrane over entire floor area, overlapping at least 150mm up walls and where damp-proof-membrane sheets meet.

-

Roll out border edge insulation and lay floor insulation. This will help to hold the border edge in place until screeding. If the floor insulation is already in place, border edging can be stapled to the edges of the floor insulation using cliprail clips or a staple gun to fix to the wall. If required, lay polythene sheets across screeded area overlapping at least 150mm up walls and where sheets meet.

-

Lay cliprail lengths at 1- to 1.2-meter intervals and as detailed on the pipe layout instructions. Use the cliprail clips to secure the cliprail to the insulation (two or three clips per rail).

-

Lay the cliprail lengths at approximately 1-meter intervals and at right angles to the direction the pipe is to be laid.

-

Check the system plans to see the number and length of each loop required.

-

Starting on one side of the manifold, connect to the manifold flow bar. Make a note of which zone the loop serves on the manifold tag supplied.

-

Lay the pipe out, navigating the most efficient route between the manifold and the zone. Start laying the pipe into the cliprail, as per the system designs. Note: Individual cliprail clips can be used to hold the pipe to the insulation in between the cliprails and on tight bends.

-

Complete the loop. Follow the same route back to the manifold and connect to the return bar (bottom bar with blue caps), making a clear note of the actual loop length installed on the manifold tag.

-

Follow the same procedure for all loops until the area is evenly covered with pipe.

-

Screed the floor once the installation of pipework is complete and the system has been pressure tested.

Additional tips

Once installed, make sure you pressure test the system. Also, be sure to mark pipes every meter to help you calculate loop lengths. Some suppliers offer pre-marked solutions.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!