John Siegenthaler: How to stage a renewable heat source with an auxiliary boiler

There are many potential applications where a renewable heat source will be combined with an existing or new boiler. The latter serves as a supplemental heat source when and if the renewable heat source is unable to supply water to the heating load at a suitable temperature.

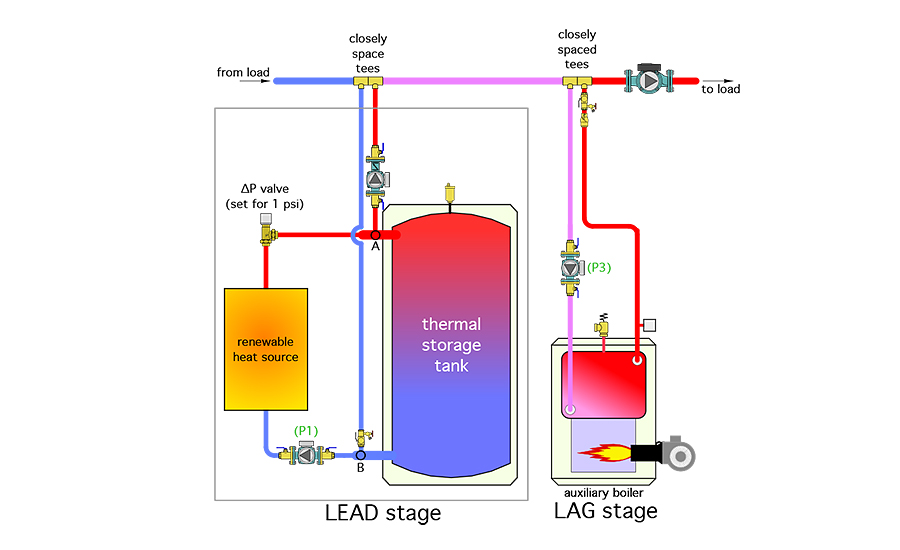

The control concept is simple: Draw heat from the renewable heat source, its associated thermal storage tank or both whenever it can supply the heating load, and when it can’t, supply the load from the auxiliary boiler. The renewable heat source becomes the “lead” stage for heat injection to the distribution system while the auxiliary boiler becomes the “lag” stage. A piping schematic that could be used for this concept is shown in Figure 1.

The renewable heat source — whether a heat pump, biomass boiler or some other device — is shown in Figure 1 along with a “two-pipe” thermal storage tank. The tank is used to store excess heat output from the renewable heat source when it’s available. The tank can also transfer heat into the distribution system when the renewable heat source is inactive. This piping arrangement also allows heat to flow simultaneously from the renewable heat source and the buffer tank under certain conditions.

Circulator (P2) provides flow from this combination of hardware, which I’ll call the “lead stage,” to the distribution system. Circulator (P2) could be operated as either “on/off” or variable speed. The latter would allow for variable-speed injection mixing between the lead stage and the distribution system.

A set of closely spaced tees provides hydraulic separation between circulator (P2) and the load circulator. Circulators (P1) and (P2) are hydraulically separated by the very low pressure drop in the common piping between points A and B in Figure 1.

The auxiliary boiler is also coupled to the distribution system by a set of closely spaced tees located downstream of the other set. This placement is important because it allows the lead stage to contribute heat to the distribution system at a lower water temperature compared to what would be possible if the connecting order of the heat sources were reversed — for example, if the auxiliary boiler tees were placed upstream of the lead-stage tees.

The ∆P valve shown above the renewable heat source should be adjusted to a forward opening differential pressure setting of 1 psi to perhaps 1.5 psi. This prevents flow through the renewable heat source if circulator (P1) is off. The forward opening pressure differential of 1 to 1.5 psi is higher than that of a spring-loaded check valve. This allows for a slightly higher pressure differential between points B and A in Figure 1 when circulator (P2) is running to move heat from the tank to the distribution system, but the renewable heat source is off. The ∆P valve also prevents reverse thermosiphoning between a hot thermal storage tank and an inactive renewable heat source.

Adding the brains

The piping in Figure 1, while hydraulically capable of providing several useful functions, cannot do so without intelligent controls.

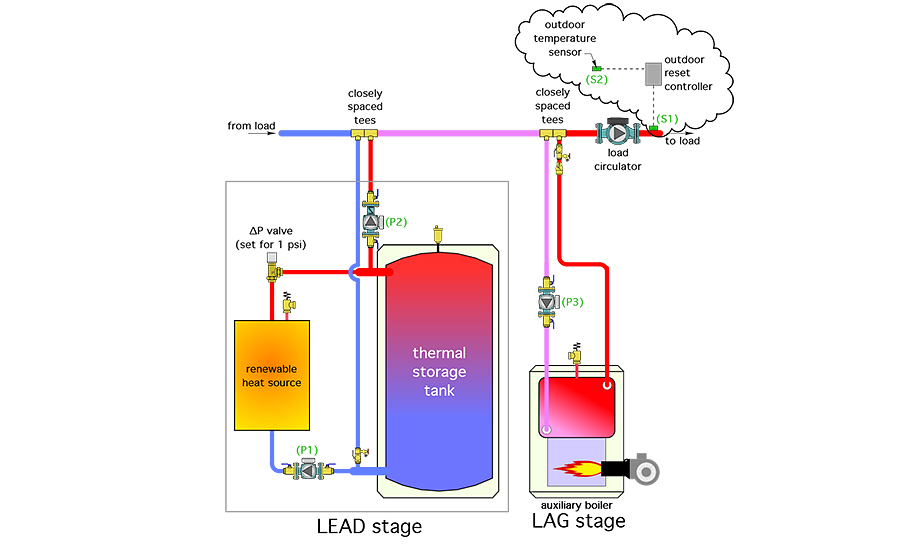

The first control function to be added determines when the auxiliary boiler needs to operate — assuming insufficient heat input from the lead stage. This is easily done using an inexpensive outdoor reset controller, as shown in Figure 2.

Whenever the load is active, the outdoor reset controller measures outdoor temperature and uses this temperature along with its settings to calculate a target supply water temperature for the load. If the actual supply water temperature measured at sensor (S1) drops slightly below this target value, the outdoor reset controller turns on the auxiliary boiler and its associated circulator (P3) to inject heat into the distribution system.

Assuming the load continues to demand heat, the auxiliary boiler and circulator (P3) remain on until the measured supply after temperature at sensor (S1) is slightly above the target temperature. This control action ensures adequate supply water to maintain comfort, but also doesn’t needlessly “overheat” the water supplied to the load. It also allows the auxiliary boiler to serve as the sole heat source if the lead stage (e.g. the renewable heat source, storage, circulator [P2], etc.) is down for service.

If the auxiliary boiler is a conventional boiler, meaning it is not intended to operate with sustained flue gas condensation, the outdoor reset controller should have a minimum supply temperature setting that’s high enough to prevent this flue gas condensation.

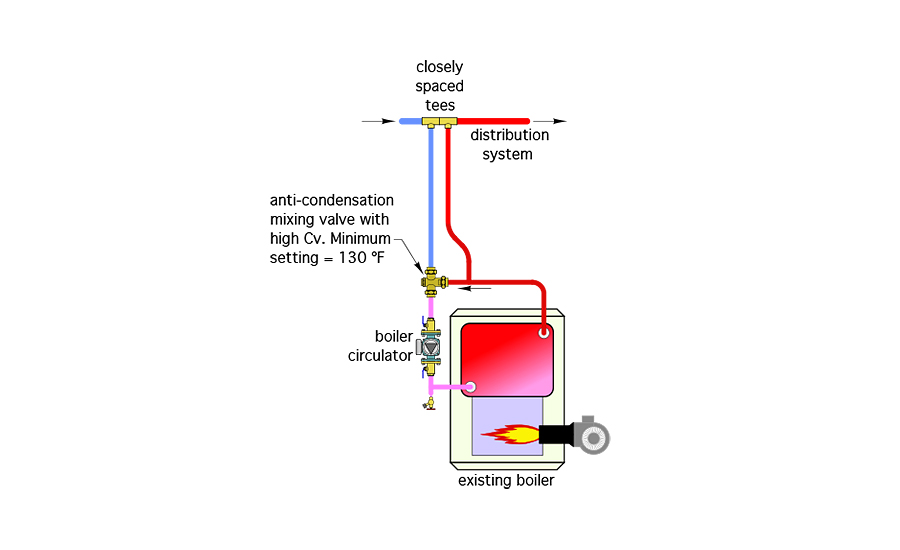

Another option is to install a thermostatic three-way anti-condensation valve on the auxiliary boiler to maintain the boiler’s inlet temperature high enough to prevent flue gas condensation, regardless how low the supply water temperature to the distribution system is controlled. Figure 3 shows how such a valve would be installed.

No backfeeding allowed

Imagine a scenario where the thermal storage tank was at room temperature and the renewable heat source was off, but circulator (P2) was running and so was the auxiliary boiler and circulator (P3). The result would be heat generated by the auxiliary boiler being inadvertently sent into the thermal storage tank.

This is not desirable from a thermodynamic standpoint. It converts high-grade energy (fuel) into a low-grade energy (heat) before that energy is needed by the load. Energy in fuel can be stored for years without degradation. But the moment that energy is converted to heat, it’s a race against time — and heat transfer — to store it in hopes of eventually sending it to the load when needed.

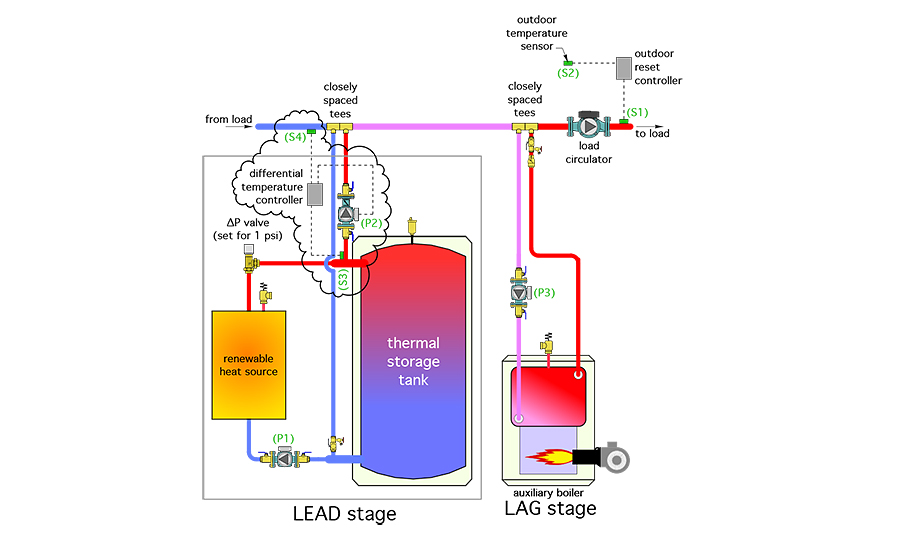

An easy way to avoid this situation is to only allow circulation between the lead stage and the distribution system when the former can make a positive energy contribution to the distribution system. This can be done using a simple differential temperature controller (DTC) to compare the temperature at the upper header of the thermal storage tank to that on the return side of the distribution system. This detail has been added to the system shown in Figure 4.

When there’s a call for heat from the load and the upper tank header is a few degrees warmer than the return side of the distribution system, circulator (P2) is allowed to operate. However, when this temperature difference decreases to a small value where the accuracy of the DTC cannot ensure that positive energy flow is occurring, circulator (P2) is turned off.

A suggested control criteria based on sensors (S3) and (S4) in Figure 4 would be:

If load is active and (S3) ≥ (S4) + 5° F, then allow circulator (P2) to run.

If load is active and (S3) ≤ (S4) + 3° F, then do not allow (P2) to run.

This logic prevents heat generated by the auxiliary boiler from being inadvertently routed into thermal storage. It also prevents flow between thermal storage and the distribution system when the temperature in thermal storage is too low to contribute heat to the load. It coordinates perfectly with the outdoor reset control logic that determines when the auxiliary boiler should operate. The warmer the outdoor temperature, the lower the temperature at which the thermal storage tank and renewable heat source can make a positive energy contribution to the distribution system.

Putting it together

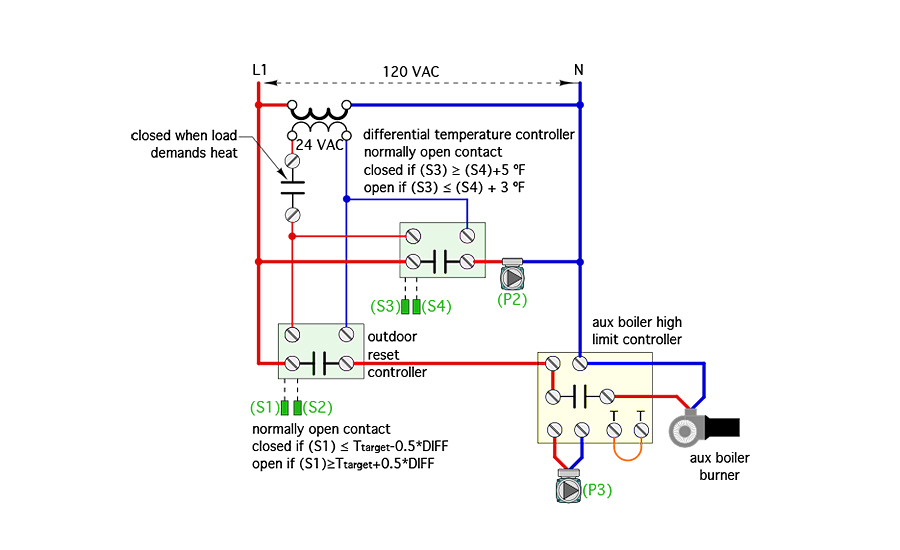

Figure 5 shows a simple electrical schematic for integrating the two control functions discussed.

A contact closes whenever the load demands heat. This passes 24 VAC to power on the outdoor reset controller and the differential temperature controller, allowing both to perform their previously described functions. The contact in the outdoor reset controller supplies 120 VAC to the high limit controller on the auxiliary boiler. The “T T” terminals on this controller are jumpered so that the controller turns on circulator (P3) and enables the burner to fire as soon as it’s powered on. Be sure to set the temperature limit on the boiler’s high limit controller high enough to prevent interference with the outdoor reset controller. A suggested setting would be 200°.

A contact closes whenever the load demands heat. This passes 24 VAC to power on the outdoor reset controller and the differential temperature controller, allowing both to perform their previously described functions. The contact in the outdoor reset controller supplies 120 VAC to the high limit controller on the auxiliary boiler. The “T T” terminals on this controller are jumpered so that the controller turns on circulator (P3) and enables the burner to fire as soon as it’s powered on. Be sure to set the temperature limit on the boiler’s high limit controller high enough to prevent interference with the outdoor reset controller. A suggested setting would be 200°.

This combination of simple relatively low-cost controllers allows accurate staging of a renewable heat source with an auxiliary boiler. It ensures that comfort will be maintained regardless of the status of the renewable heat source while also allowing the latter to make a positive energy contribution to the load whenever possible. Perhaps you can find a way to integrate this piping and associated control logic into a future project.

This article was originally titled “Making a positive contribution” in the July 2018 print edition of Plumbing & Mechanical.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!