The General Society of Mechanics and Tradesmen of the City of New York has a unique home

Saving a piece of NYC history

The building at 20 West 44th Street is home to The General Society of Mechanics and Tradesmen of the City of New York. Photo credit: John Cataneo

The GSMT building began in 1890 as the Berkeley School for Boys, but the school failed. The General Society bought the building in 1899 and added two wings and three stories to its existing four stories. Photo credit: John Cataneo

In this three-pipe system, the left pipe was a steam supply riser, the right was the condensate return that would also carry steam in counterflow to the condensate, and the center pipe is the remnants of Andrew Paul’s vacuum system, now abandoned in this building. Photo credit: John Cataneo

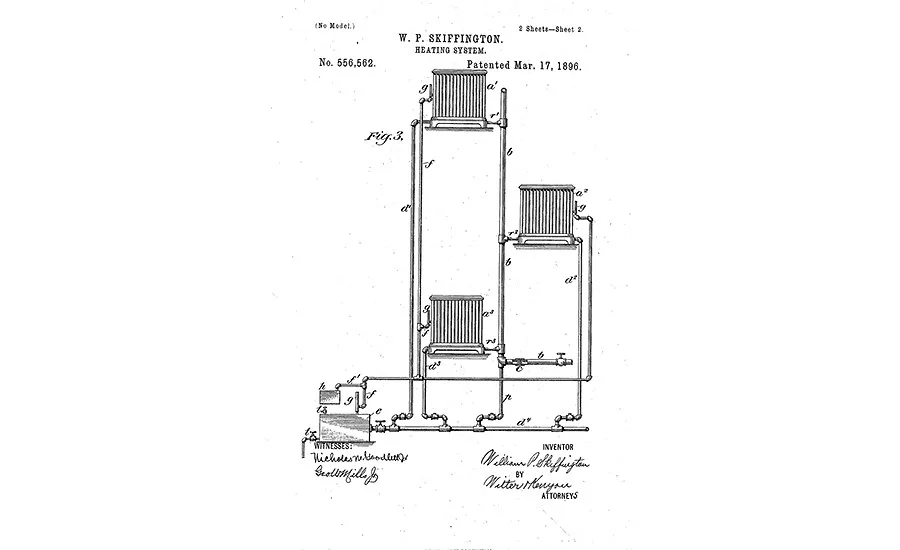

The patent for what came to be known as The Paul System.

The old brick-set boilers in the GSMT building once burned coal, and each was 10 feet high, 10 feet wide and 20 feet long. Photo credit: John Cataneo

The upgrades to the steam heating system at the GSTM building in New York City reduced the building’s steam consumption by 43%. Photo credit: John Cataneo

Step off of West 44th Street and into the lobby and look to your left. The artists — and we must call them that — who crafted that magnificent marble staircase were masters. You can tell.

They knew they were working on something that would last much longer than their own lives, and it has lasted 114 years so far. They knew that generations would walk these marble steps every day, again and again, and most would never know the names of the builders. But that didn’t matter to the builders; only the work mattered.

Article Index:

- A secular cathedral

- My blind date

- Dead men

- Next stop: the basement

- Back to the 90s

- Taking control

- Preserving history

And they worked with such pride. You can tell. Climb these steps and you’ll feel beneath the soles of your shoes the steps of tens of thousands of others who have ascended and descended before you. Each scuffed into the air a few molecules of stone and left behind depressions in the marble that you can feel. These depressions represent lives lived and good work accomplished. You can feel it all there beneath your feet.

There will be more centuries of scuffing in this very special place long after we’re gone. And perhaps, if we do our jobs as well as they once did, those who are to come after us will think of us, but never know our names.

And that will be good enough.

A secular cathedral

In January 2015, the Association of Energy Engineers invited me to Manhattan to talk to them about steam heating. Afterward, one of the members asked if I would be interested in giving a similar talk at The Mechanics Institute on West 44th Street. That made me smile.

The Mechanics Institute is a part of The General Society of Mechanics and Tradesmen of the City of New York. Twenty-two skilled craftsmen met in a tavern in lower Manhattan and agreed to look out for each other, and to take care of their widows and the orphans. Forever.

The year was 1785, and the British had just sailed away from New York, leaving behind a city fractured by war.

The 22 grew into thousands as the years went by.

In 1820, The Society opened the first free school in New York as well as a library for apprentices. They also educated girls, which was unheard of at the time. They did that 38 years before New York City had a public school system.

And then, once the city stepped up with free public education, The Society converted their school into a tuition-free Mechanics Institute, based on a Scottish model of furthering the education of those already working in the trades.

The Society has been at it ever since. Each year, more than 350 students who work in the trades during the day take tuition-free courses at night at the Mechanics Institute. The two- and three-year programs have graduated tens of thousands of students who went on to build this city we call home: New York.

The Society also opened their membership library in 1820; it is the second oldest library in New York and still going strong.

So I said “Yes!” to the invitation to speak at this landmarked building at 20 West 44th Street, which I have long considered to be a secular cathedral. Never in my wildest dreams did I think I would ever be invited to speak at this place. Who the heck am I?

My blind date

Victoria Dengel, The Society’s executive director, sent me a formal letter of invitation (this place is cool like that), and she asked if I would like to visit ahead of my talk and take a look at the building’s heating system, which had been warming the place for more than 100 years.

I said, “Yes!”

We met a few days later and Dengel told me that before I could see the building, I first had to meet her parents.

Dengel walked me to a photo of a banquet that took place years ago and she pointed out her mom.

“She’s right her at this table,” Dengel said, her finger lingering lovingly on the image of her late mother. She had me with that gesture.

“And my dad is over here,” she said, walking toward the rows and rows of photos in the world-famous John M. Mossman Lock Collection room. I followed and she pointed, again pausing to remember her father. And she had me again. I felt like I was on a blind date with a building, which I sort of was.

And it was love at first sight.

Dengel’s dad had been an operating engineer. Those are the people with the big cranes. He was also a past president of The Society, and so was Dengel, I learned, but her photo wasn’t on the wall with her father’s photo. I asked about that and she explained that the photos of living past presidents are in her office.

“The dead are here,” she said gesturing.

And isn’t that lovely? The living reside in the room where the business goes on; the dead rest with the memorabilia.

I looked up again at all the male faces (Dengel is the only woman to have ever served as president of The Society) and marveled at the beards and moustaches. I wanted to sit and listen to each one of those, and I said so, which made Dengel smile.

“I’ve been coming to this building since I was 11 years old,” she said. “I’m still discovering things. The other day we were moving a file cabinet and we found a very old bow-and-arrow and a musket behind it.”

You know the movie “Night at the Museum”? Yeah, it’s like that here.

But about the steam heat.

Dead men

The dead presidents’ photos hang in the world-famous Mossman Lock-Collection room, which has hundreds of rare locks, one of which dates back to 4000 B.C. That alone is worth a visit, but my eyes were on these three pipes. That trio of pipes told me what I would find in the rest of the building.

The pipe on the left was one size larger than the pipe on the right, and the pipe in the middle was relatively small compared to the other two.

The one on the left was a steam supply riser. The one on the right was the condensate return, but in this system, it would also carry steam in counterflow to the condensate. And the pipe in the middle was the remnants of Andrew Paul’s vacuum system, now abandoned in this building.

“Please show me a radiator,” I said to Dengel. She took me into her office and I saw this gorgeous Italian Flue radiator from the 1890s. It had two hand valves, both on the same side of the radiator. There was a small hole in the floor between the two valves and that was where the vacuum line used to be. The radiator had a standard one-pipe-steam air vent where the Paul vent used to be.

Paul was the General Sales Manager of Fairbanks Company. He originated the design of the Fairbanks valve way back in the late 1800s.

He was sitting in his office one day, looking up at the steam coil in the skylight that was giving them all fits. The steam coil below the skylight kept binding up with air, which kept the steam from entering. And where there is air, steam will not go. That’s why we use steam air vents on one-pipe-steam radiators. But since this coil was air-bound, condensate was forming on the inside of the skylight and water was dripping onto the folks below. Not a good situation, and one that had Paul stumped.

But then he came to work one day and noticed to his delight that the coil was now working and the skylight wasn’t dripping water. He looked more closely and spotted a small pipe that connected to the outlet of the coil. It had not been there before. His friend and coworker, Bill Skiffington, looked over at him and smiled. Skiffington had added that pipe, hooking it up to a small vacuum pump to get rid of the air that was blocking the steam.

“Great Scott, man,” Paul said. “Do you realize what this means? You must get this patented at once!”

This was in 1891, and Skiffington took Paul’s advice. He applied for the patent right away, assigning a three-quarter interest in any profits to Paul, who had the money to make things happen.

And things did happen — slowly at first, but then they really took off. Paul organized the New England Engineering Company in Boston and set out to develop the science of vacuum steam heating. Paul decided to charge contractors a royalty of $0.02 per square foot of radiation to use their patented system, and in a big building, that can add up.

After a while, he reorganized as the Paul Steam System Company, and later, a Chicago company formed as the Western Paul Steam System Company. They also paid him royalties.

In 1900, Albert A. Cryer and Associates set up the Paul System Company of New York and went to town installing the Paul System in many of the bigger buildings throughout Manhattan. By using their patented system of ejectors, they produced a vacuum that sucked the air from the pipes and the radiators, allowing the steam to rocket from the boiler to the where the people were. Old magazine ads claimed that this system could cut the fuel bill by 30%, and that had building owners lining up to get it.

Albert A. Cryer and Associates was clearly involved in the 1903 expansion of GSMT’s home on West 44th Street. The building has started life in 1890 as the Berkeley School for Boys, but the school failed and The General Society bought the building in 1899 and added two wings and three stories to its existing four stories. It was to be their fifth home in Manhattan. Andrew Carnegie, a General Society member, donated $250,000 for the construction (that’s about $6.6 million in today’s dollars), and he later doubled that amount.

The Society’s library has a soaring atrium crowned by a huge skylight. There are steam pipes around the entire perimeter of that skylight. They look decorative, but they’re there to keep the glass warm. The Dead Men knew what they were doing.

When I became a member in 2015, I signed the same leather-bound ledger that every other member has signed since 1785. I asked to see Brother Carnegie’s signature in the ledger. Next to his name, where every member listed their trade, he had written “Cotton Spinner.” When he signed, he was the wealthiest man in the world, but he said that he wanted to be remembered for his days as a tradesman. Humility. I love that.

As we walked the building looking at radiators, we met Alex Weiss, a professional engineer and one of the Mechanics Institute teachers. He told me there is one radiator in the pump room on the top floor that still had the original equipment. We went there and sure enough, the Paul vent and its pipe were in place. Now we all knew for certain exactly what we were dealing with.

“I have an outside engineer’s report,” Dengel said. “They’re making a lot of suggestions to improve the system, but it looks like it’s going to be very expensive to do all of this.”

She gave me a copy of the report, but redacted the name of the company making the suggestions. Fair is fair.

The report recommended that every radiator get a thermostatic trap. This would have been not only costly, but also crazy. This was now a two-pipe, air vent system. There’s supposed to be steam in both the supply- and return risers. That’s the way this circa-1900 system works. Adding steam traps would have massively complicated the system, and at great expense. It would have done nothing to solve the problems the building was having, which included psychotic water hammering in the pipes and ridiculously high steam bills.

“Please don’t hire these people,” I said.

“OK,” Dengel said.

Next stop: the basement

The staircase is as steep as a ladder and I went down backwards. It was steamy down there from a leaking main valve that connected to ConEd’s steam line under West 44th Street.

“That valve has to be fixed,” I said. “The steam is undermining the concrete.”

“Yes,” Dengel said.

And then I saw the old brick-set boilers. There were two of them and they were face to face, like two old men waiting for the other to say something. They once burned coal, and each was 10 feet high, 10 feet wide and 20 feet long. The iron doors were cast with the name of the manufacturer, who was also the engineer and the installation contractor. It read:

James Curran Mfg Co

Heating Engineers

New York City

I later learned that James Curran Manufacturing did business out of their building at 512 West 36th Street in Manhattan, half a block from the Jacob Javits Convention Center, occasional site of the big AHR show. I tried to think of a time when a company could have made boilers that size in a city this tight, and just a few blocks from R.H. Macy’s.

The two boilers smiled at me because I was thinking those thoughts.

Now when the boilers were up and roaring, this system would have been relatively simple. The Paul System would have sucked the air from the pipes and the radiators. The steam would have raced up the seven stories to the top-floor radiators and the condensate would have drained by gravity into the wet return. As the system heated, the steam would have crossed through the radiators and traveled upward toward the Paul vent lines as condensate flowed in the opposite direction. This is classic 1890s big-building steam heating, and our goal was to get it back as close to its original state as we could. Instead of the Paul vent lines, we would use thermostatic radiator valves between the radiators and the radiator air vents for control.

The reason the system was suffering from water hammer was because of ConEd’s district steam. When the building switched from the boilers to ConEd in the mid-90s, the contractor cut all of the wet returns loose from the abandoned Curran boilers. He put a huge steam trap at the end of each of those old wet returns and directed those traps toward a very large condensate pump. The pump’s job would be to gather the condensate and pump it to the sewer. ConEd doesn’t want any of the condensate back, so it all gets dumped. If you think that sounds like a massive waste of water and heat, you would be correct.

By law, we have to bring the condensate temperature below 150° F before dumping it into the sewer, and the contractor tried to do this by using finned-tube radiator piping for the dump line. That made the basement even hotter.

To make things crazier, the big condensate pump was in a wide concrete pit that was nearly 4 feet deep. This pit regularly filled with water, and the pit’s sump pump couldn’t keep up with it, so the condensate pump’s motor went underwater regularly. When the condensate pump failed, the condensate would back up into the former wet returns, which now carried steam, and the water hammer showed up to rock the building on its foundation.

With me so far?

Good.

But before we go any further, I have to tell you why that pit was flooding. When I first watched it happen, I thought a pipe had broken, but all the pipes were visible and there were no leaks. The water was just coming right through the concrete.

So I wondered what was under the building, and that brought me to Elbert L. Viele. Ever hear of him? He was a map man. In 1865 he hand-drew the most extensive topographical map ever made of Manhattan Island and all of its waterways. He did this because everyone knew that there were going to be a lot of buildings going up over those marshes and streams and that Mother Nature doesn’t care what you build over her water. Her water is still going to do what it does.

I got a copy of Mr. Viele’s famous map, which has the proposed NYC street grid superimposed over the waterways. None of those streets or buildings existed yet but I found the location of where The General Society’s building would be a few dozen years later. It would sit directly on top of a marsh. That’s what we were seeing in the pit each morning. The ancient marsh.

And then I saw that our marsh flows eastward toward Fifth Avenue and then northward one block to East 45th Street, where it joins with a stream underneath the beautiful art deco Fred French building. From there it joins other streams and these all dump into the East River at East 32nd Street.

I asked our friends at Ferguson if they would donate a high-temperature sump pump to The Society, and they did. Good people.

Back to the 90s

The 1890s, that is.

We formed a group of Society members and dubbed ourselves “The Steam Team.” John Cataneo of Gateway Plumbing and Heating took the lead on the basement piping. Alex Marx would look into the old Heat-Timer control. Weiss, a professional engineer, and James Gallo of Leviathan Mechanical helped us think it all through, and Arthur Klansky of Ashlar Mechanical replaced that critical main steam valve that was spewing high-pressure steam into the basement.

With the steam valve replaced, our next job was to recreate a wet return so we could fool the pipes and radiators into thinking that the old Curran boilers were back on the job. John and his Gateway guys cut out the big F&T traps that dumped super-hot condensate into the condensate transfer pump in the pit. They also sent the pump to the dump.

Next, they joined the ends of what was once the wet return at the places where the F&T traps had been and turned them vertically into the bottom of a large compression tank John had salvaged from another old building in Manhattan. He had a welder add piping and gauge glass connections at strategic points at the tanks ends and sides. We call it “the bottle.”

They equalized the top of the bottle with steam so the pressures on both sides of our new wet return balanced like a seesaw. This prevented the steam from shoving the water out of our new wet return. Now, when the condensate returned, instead of flowing into the condensate pump, it rose and filled the bottle. This filled the new wet return across the whole building, and we all said, “Hello, 1890!”

But we now had to get the condensate out of the bottle and over to the drain, and we had to cool it before we could dump it. We did this by installing two one-inch F&T traps into the side of the bottle, one higher than the other. When condensate reached the lower of the two traps, positioned to replicate the Curran boilers’ waterlines, the trap would open and the condensate would flow by gravity toward a Taco water-to-water shell-and-tube heat exchanger. The condensate would preheat the domestic hot water in that exchanger.

On days when the condensate load was high, the water in the bottle would continue to rise because one trap wasn’t large enough to handle the whole load, so the second trap would join the first and go into action. The reason we used two traps and not one was because a single trap sized for entire whole building load would have barely opened on days when the condensate load was light, and that would have damaged the trap by wiredrawing its seat.

I sized those traps by looking at the building’s steam usage during the coldest month of the year. We had those records from ConEd. We needed just two 1-inch traps for the entire building. Numbers don’t lie. The old system had two 2.5-inch traps because that was the size of the old wet returns that the ConEd conversion had turned into steam mains. Those traps were ridiculously oversized, and that was why they had been failing. It’s always a dumb idea to line-size an F&T trap. Always.

When the system started up, we learned that the new wet return cooled the condensate to a point where we didn’t even have to run it though the Taco heat exchanger, but we wanted to reclaim as much heat from the water as possible to preheat the domestic hot water. We decided to add a second steam-to-hot-water heat exchanger in series with the other exchanger for times when we needed a boost to the domestic-hot-water temperature.

Taco’s owner, Johnny White, is a Society member, and he graciously donated the exchangers as well as several domestic hot water recirculation pump setups. The building’s domestic water piping then became a storage “tank” for the hot water, and the recirc pumps moved the water through the building and the two heat exchangers as needed.

Oh, and we added a single, 40-gallon electric water heater to that loop. There used to be two gas-fired water heaters in the basement, but these were venting into the old boiler’s chimney, which gave us concern because of its enormous size, so we abandoned those gas-fired units and replaced them with the electric heater, which Ferguson also donated. As I said, they’re good people.

Oh, and our friends at Barnes & Jones donated those two F&T traps. Another fine company.

The system started up and has been silent ever since.

If I had a handlebar moustache, I would have twirled it and smiled right about then.

Taking control

ConEd steam enters the building at about 160 psig and more than 350°. ConEd sends us steam at that pressure because they can move an enormous amount of energy through relatively small pipes under the city streets when the steam is under pressure.

When it arrives at the building, though, we have to lower the pressure, and we do this in two stages with pressure-reducing valves. The first brings the pressure down to 50 psig, and the second takes it down to about 2 psig.

This is standard practice with high-pressure district steam. You can’t lower it from 125 psig down to 2 psig with a single PRV because that PRV would be hunting all over the place and soon fail. Using two stages avoids that problem.

The Heat-Timer in the building was very old, so Marx looked into it. Marx, also known as The Wire Nut, is a savant when it comes to all things electrical. He learned that if he set a few of the switches just so, the Heat-Timer would be better able to deal with ConEd steam.

In a building served by its own boiler, the Heat-Timer would start the boiler when the outdoor temperature reached a chosen low point. The steam would travel out into the building, where a thermister would sense its temperature.

The placement of that thermister is critical because it begins the countdown-to-shutoff cycle for the burner, and the outdoor temperature determines that. For instance, on a day when it’s 40° outside, the burner may run for 20 minutes after the thermister feels heat and then shut down for the next 40 minutes. The colder it gets outside, the longer the countdown to shutoff will be.

With ConEd steam, we’re not shutting down a burner; we’re closing the main PRV, and in The Society’s building, the PRVs are pneumatic, so we need to control the air signal to the first PRV. Marx took care of that.

But because of the age of the Heat-Timer, we had some control issues to deal with. The outdoor temperature in New York City has been swinging back and forth lately, and the old control wasn’t smart enough to follow all of that. Cataneo spoke to his friends at Heat-Timer and they agreed to donate a new, much-smarter, state-of-the-art Heat-Timer — “MPC Platinum” — to The Society. This is the device the Gateway guys use for online performance monitoring and remote adjustments of any settings. Heat-Timer has been making advanced steam controls since 1937.

There was one more important piece to our puzzle and our friends at Tunstall Corp. in Chicopee, Massachusetts, stepped up to solve that for us. Tunstall sells repair parts for just about every steam trap ever made. They also sell inlet orifices that meter the flow of steam into a radiator. That’s old-school stuff, and those orifices can work wonders on any old steam system. Tunstall also distributes Macon thermostatic-radiator valves, and that’s just what we needed.

Since the radiators at The Society are now on a two-pipe air-vent system, we can’t effectively control the steam as it enters any of the radiators. We can, however, control the air that leaves a radiator. And when we stop the air from leaving, the steam can’t enter. Tunstall donated more than 100 of these fine Macon TRVs to The Society, and Gateway Plumbing and Heating installed them all in two days. Now, every tenant has control over the amount of heat they have in their space, and the tenants are no longer opening the windows in the dead of winter.

I can’t thank companies like Tunstall, Taco, Barnes & Jones, and Ferguson enough for their generosity on this project. They allowed us to save heating history with very little cost to The Society. And that means that the Mechanics Institute now has more money available to continue their mission of offering free continuing education to thousands of eager students currently working in the trades.

The Society’s building is at 20 West 44th Street in Manhattan. That one block between Fifth Avenue and Avenue of the Americas is home not only to The Society, but also to the Harvard Club, the New York Yacht Club, the Penn Club (which was once the Yale Club), and the lovely old Algonquin Hotel. These are all landmarked buildings, and they’re all gorgeous. I can’t walk that block without stopping and smiling. Such beauty lovingly conserved. This is part of what makes a city great. We respect our history.

Preserving history

Why save an old heating system? Why didn’t we rip it all out and put in mini-splits? That’s the modern thing to do, right?

Well, if you could see these radiators, you’d probably understand. They are works of art and they are a part of this iconic building. Plus, we knew we could get rid of the water-hammer noise, and we knew we could balance the heat throughout the building with the new Heat-Timer and the Macon TRVs.

We knew we would wind up with a system that has few moving parts and need little service. It runs on gravity, and gravity will always be available.

And, as I said, since we used GSMT-member knowledge and labor, we did all of this for very little cost to The Society, which means students can continue to climb those marble stairs to their night classes at The Mechanics Institute. They can improve their lives without going into debt.

That’s why.

And here’s my favorite part, and one I fully expected: The improved system had been running for several months when ConEd called to say they were sending a crew to change the building’s steam meter. There must be something amiss because our steam consumption had gone down by 43%.

They probably thought we had bypassed the old meter.

The crew went away scratching their heads.

See? You don’t have to rip things out and begin anew to make things better. You just have to know what you’re dealing with, and you have to know your heating history.

Last year, NYC Mayor Bill de Blasio announced “One City, Built to Last: Transforming New York City’s Buildings for A Low-Carbon Future.” The plan’s goal is to upgrade every public building with significant energy savings by 2025, and then to follow with the same plan for privately owned buildings. If the building owners don’t reach their assigned energy reductions, mandates will follow. They’ll be forced to abandon their steam systems. And we’re talking buildings of all sizes, including single-family homes. We’re becoming more and more like Europe in this way.

What will replace the steam? Those in power are talking about air-to-air heat exchangers. They’re saying that steam can’t possibly be efficient, and that all the steam systems in New York City’s older buildings are beyond redemption.

I’ve invited those folks to visit The General Society of Mechanics and Tradesmen of the City of New York, founded in 1785, and still doing things others say can’t be done.

My hope is that these people are teachable because history has much to teach.

We’ll see.

This article was originally titled “Saving a piece of NYC history” in the March 2018 print edition of Plumbing & Mechanical.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!