You don't pay for COPs

The higher the COP, the greater the desired output is relative to the required input.

Figure A. The higher the COP, the greater the desired output is relative to the required input. Photo credit: John Siegenthaler

Formula 1: The annual savings in heating energy between two heat pumps with different seasonal average COPs can be estimated using Formula 1. Photo credit: John Siegenthaler

Figure B. The other heat pump has a seasonal COP of 2.8. Putting these values into the formula above yields. Photo credit: John Siegenthaler

Figure C. For example, if electricity sells at a flat rate of $0.13 per KWh, the cost savings would be as is. Photo credit: John Siegenthaler

Figure D. Thus, the savings associated with a “super duper” heat pump yielding a seasonal average COP of 4.0 versus one with a seasonal COP of, say, 2.5 in a building with a design load of only 18,000 Btu/h, in Syracuse, would be as is. Photo credit: John Siegenthaler

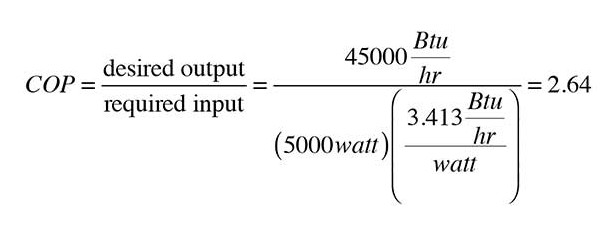

The measure of a heat pump’s heating performance is called coefficient of performance (COP). It’s simply the ratio of useful heat output divided by required energy input, where both the output and input are expressed in the same physical units.

For example, if an air-to-water heat pump delivers 45,000 Btu/h of heat output to a stream of water and has a power input of 5,000 W, its COP, under those specific operating conditions, can be calculated as follows:

Figure A. The higher the COP, the greater the desired output is relative to the required input. Photo credit: John Siegenthaler

The higher the COP, the greater the desired output is relative to the required input. Thus, higher COPs are always preferred, all other things being equal.

Although higher COPs result in lower electrical energy consumption, it’s important to realize that the person paying the bill for heating a building doesn’t pay for COP. They pay for the Kilowatt • hours (KWh) of electrical energy necessary to run the heat pump. This is an important distinction, and one that’s often misinterpreted when evaluating the merit of one heat pump versus another.

So, how is one supposed to evaluate various heat pump options with differing COP information and different installed cost? Start by understanding that COP can be calculated in several ways.

The two most common ways COPs are expressed are:

- As an instantaneous performance index; and

- As a seasonal average value.

The instantaneous COP of any heat pump is strongly dependent upon all of the following:

- The temperature of the material from which low temperature heat is being absorbed;

- The temperature of the material to which higher temperature heat is being released;

- The flow rate of the material supplying the low temperature heat (e.g., air or water) across the heat pump’s evaporator; and

- The flow rate of the material absorbing the higher temperature heat (e.g., air or water) across the heat pump’s condenser.

Most heat pump manufacturers list the COPs of their heat pumps under specific combinations of the above conditions. Those conditions are usually referenced to some industry standard, which should make it easier to make “apples-to-apples” comparisons.

It’s also important to realize that if any of these four operating conditions change, so will the COP and heating capacity of the heat pump. Under favorable operating conditions, it’s possible for just about any heat pump to have impressive COP values. Unfortunately those favorable conditions, which represent a “snapshot” of performance, don’t exist over an entire season (if at all).

Conditions change

When evaluating seasonal heating cost, it’s important to use a COP that reflects the wide range of operating conditions the heat pump will experience over an entire heating season. These “seasonal average COP” values are not published by heat pump manufacturers because they don’t know what conditions the unit will operate under.

Still, it’s possible to simulate those conditions using software that factors in either hourly data for outdoor temperature or bin temperature data, and in the case of geothermal heat pumps, algorithms for heat transfer for specified earth loop configurations. Software simulations also have to account for the variations in the heat pump’s heating capacity and COP under all these conditions.

In some cases, the simulation may also have to adjust for time-of-use electrical rates. Such rates, where available, can significantly impact the operating cost for heat pumps that operate a high percentage of their total run time under lower “off-peak” rates.

The result of such a simulation would be a reasonable estimate of the heat pump’s seasonal average COP, and that would be the performance index appropriate for making operating cost comparisons.

One vs. another

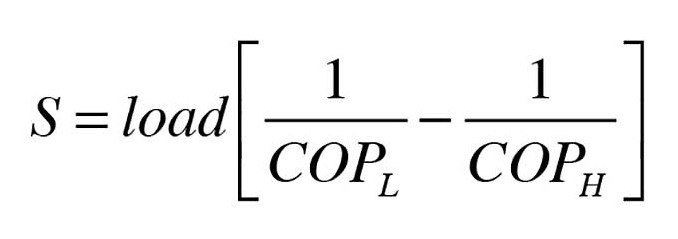

The annual savings in heating energy between two heat pumps with different seasonal average COPs can be estimated using Formula 1:

Formula 1: The annual savings in heating energy between two heat pumps with different seasonal average COPs can be estimated using Formula 1. Photo credit: John Siegenthaler

Where:

S = savings in seasonal heating energy (MMBtu*)

load = total annual heating energy required for the building (MMBtu*)

COPL = seasonal average COP of heat pump having the lower of the two COPs

COPH = seasonal average COP of heat pump having the higher of the two COPs

*1 MMBtu = 1,000,000 Btu

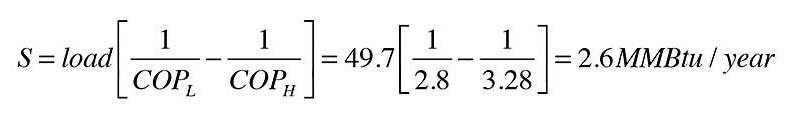

Here’s an example: A house has a design heating load of 36,000 Btu/h when the outdoor temperature is 0° F and the indoor temperature is 70°. The house is located in Syracuse, N.Y., with 6,720 annual heating °F • days. The estimated annual space heating energy use is 49.7 MMBtu. Assume that one heat pump option has a seasonal average COP of 3.28. The other heat pump has a seasonal COP of 2.8.

Putting these values into the formula above yields:

Figure B. The other heat pump has a seasonal COP of 2.8. Putting these values into the formula above yields. Photo credit: John Siegenthaler

The cost savings associated with an energy savings of 2.6 MMBtu/per year depends on the cost of electricity. For example, if electricity sells at a flat rate of $0.13 per KWh, the cost savings would be:

Figure C. For example, if electricity sells at a flat rate of $0.13 per KWh, the cost savings would be as is. Photo credit: John Siegenthaler

Perhaps you’re wondering where the two seasonal average COP values used in this example came from. I would be happy to tell you.

The seasonal average COPH of 3.28 came from a software simulation of a geothermal water-to-water heat pump supplying warm water to a hydronic radiant panel heating system in the Syracuse house (36,000 Btu/h design load). The radiant panel was assumed to require a supply water at 110° under design load conditions. The software used for the simulation was supplied by the heat pump manufacturer.

The seasonal average COPL=2.8 also came from a software simulation. In this case, the software came from a manufacture of air-to-water heat pumps. This software simulation was also based on the same Syracuse house and the same radiant panel delivery system.

The entire balance of system downstream of the heat pumps was identical, as were the load conditions.

About now you’re probably thinking: Can an annual savings of $99 realistically amortize the higher installed cost of the geothermal heat pump within a reasonable time? The only way to address this is by making an installed cost estimate for both systems, factor in any currently available rebates or tax credits and see what the difference would be.

Here are the assumed (yet realistically estimated) values I will use for the comparison.

The geothermal system was assumed to be supplied from earth loops contained in vertical boreholes, which in the upstate New York area go for about $3,000 per ton of capacity for the borehole, U-tube piping and grouting. The estimated installed cost of the complete earth loop, including manifolding the individual “U-tube” in each borehole, routing everything back through the basement wall and restoring all affected landscaping, was $11,800.

The installed cost estimated for the balance of system including the heat pump, circulators, loop fluid, piping, etc. (but excluding the radiant panel heat delivery system, since it would be the same for both heat pumps being compared) was $8,750. The total estimated of the heat pump and earth loop, excluding the radiant panel distribution system, is $20,550.

The estimated installed cost of the air-to-water system (again excluding the distribution system) was $10,600. The difference in net installed cost between these two systems would be $9,950.

So, the simple payback of the assumed geothermal heat pump system compared to the assumed air-to-water heat pump system, and assuming no change in electrical rates is $9,950/$99 = 100.5 years.

You decide if that’s acceptable.

For the record, New York recently began an incentive program providing $1,500 per ton rebate to qualified new installations of geothermal heat pumps. Since the project being discussed was assumed to be in Syracuse, this new rebate would lower the installed cost of the geothermal heat pump system by $4,500. This difference in installed cost would be $5,450, and the simple payback would drop from 100.5 years to 55 years. Again, I’ll let you judge the practicality of this reduced payback period.

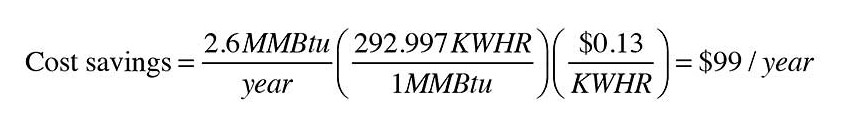

Shrinking loads = shrinking savings

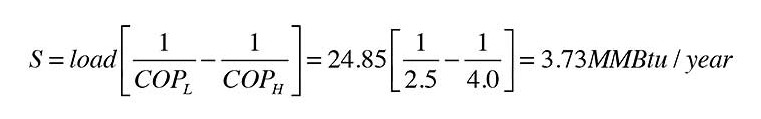

As energy codes become more stringent — and the market for low energy buildings, net-zero buildings and the like grows — the energy savings associated with different COP values decreases in direct proportion to the annual space heating energy use. That’s evident in Formula 1. Cut the load in half and the savings are cut in half. Thus, the savings associated with a “super duper” heat pump yielding a seasonal average COP of 4.0 versus one with a seasonal COP of, say, 2.5 in a building with a design load of only 18,000 Btu/h, in Syracuse, would be:

Figure D. Thus, the savings associated with a “super duper” heat pump yielding a seasonal average COP of 4.0 versus one with a seasonal COP of, say, 2.5 in a building with a design load of only 18,000 Btu/h, in Syracuse, would be as is. Photo credit: John Siegenthaler

At a going rate of $0.13 per KWh in that area, the annual savings would be about $142 per year. That’s about 24% of what many households spend for a year of internet service at $50 per month. It’s something to think about when contemplating a very high-performance, but very pricey, heating system for a low energy house. The eco-cocktail-party bragging rights are there, but the financial case is “economically unsustainable.”

The bottom line

COPs for heat pumps, like AFUE values for boilers and SEER ratings for air conditioners, are often presented as numbers that energy-conscious consumers should be very excited about. That’s understandable from a sales perspective. However, the numbers that count are those your clients will see on their utility bills, and there’s no line item on those bills for COP.

To read Siegenthaler’s article “You don't pay for COPs” in pdf form, please see here.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!