Details Matter

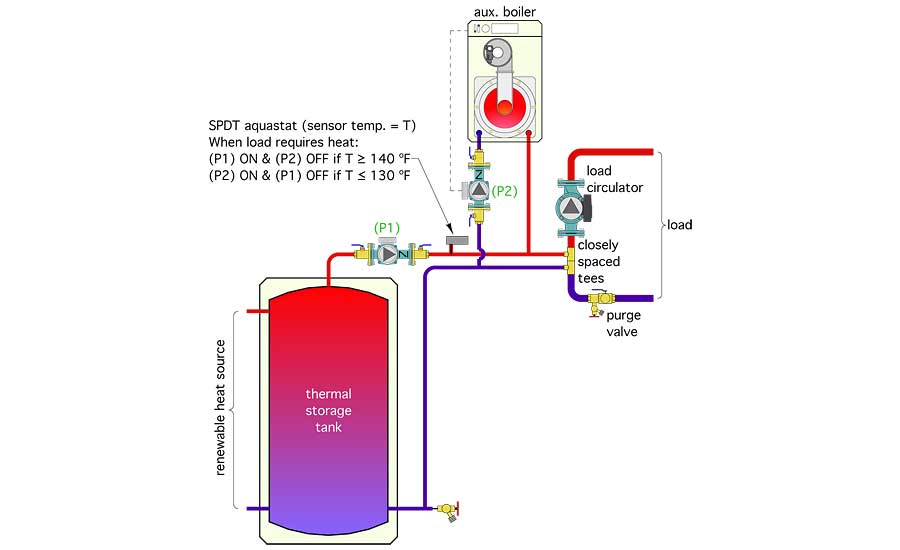

Figure 1. The Glitch. Do you see any other details that should be changed?

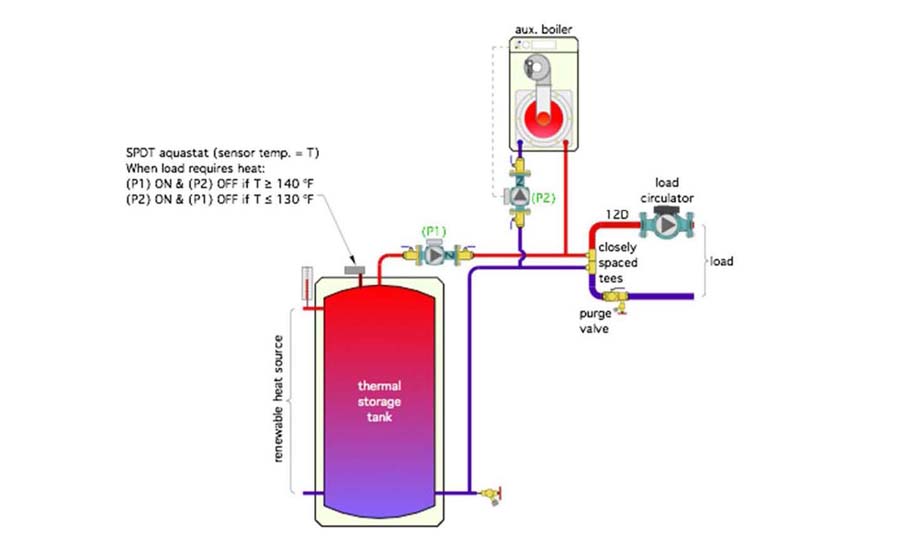

Figure 2. The Fix. The aquastat needs to sense the water temperature at the top of the thermal storage tank.

The Glitch:

An installer needs to connect a thermal storage tank that’s heated by a renewable energy heat source, along with a mod/con auxiliary boiler. Both will supply a common load.

When a heating load is present, and the load circulator turns on, the tank is to supply the load if the water at the aquastat is at or above 140°. In this case circulator (P1) needs to run and circulator (P2) and the auxiliary boiler should be off. If the temperature at the aquastat is less than or equal to 130°, the auxiliary boiler should be on, circulator (P1) should be off, and circulator (P2) should be on.

During a follow up site visit the installer notices that the temperature at the top of the tank is 145° F, (P1) is off, and the auxiliary boiler and circulator (P2) are supplying heat to the load. It’s not supposed to work like that.

Circulators (P1) and (P2) both have internal spring‐loaded check valves. Assuming that the aquastat is operating correctly, and that essential details such as an expansion tank, PRV, etc. are all present and correctly installed (they’re just not shown), why is the system behaving this way? Do you see any other details that should be changed?

Figure 1. The Glitch. Do you see any other details that should be changed?

Figure 1. The Glitch. Do you see any other details that should be changed?

The Fix:

When it comes to temperature control: If you can’t sense it, you can’t control it.

In the glitch drawing the aquastat is located downstream of a circulator with an internal spring‐loaded check valve. That valve prevents water in the tank from reaching the aquastat’s sensor unless circulator (P1) is operating. The thermal storage tank could be filled with hot water, well above the required 140° temperature, but when the heating load occurs, the aquastat is “feeling” a temperature well below the 130°. The auxiliary boiler and circulator (P2) turn on to satisfy the load. The building remains comfortable, and the owner is unaware of the issue. It may not generate a call back, but it’s not right, and any responsible heating pro should determine there’s a problem and fix it.

The control concept is fine, and the fix is simple: The aquastat needs to sense the water temperature at the top of the thermal storage tank (as shown in the fix drawing).

A couple of other details that should be fixed:

The purge valve in the load circuit is installed backwards.

The load circulator should have at least 12 pipe diameters of straight pipe upstream of its inlet to suppress turbulence.

Figure 2. The Fix. The aquastat needs to sense the water temperature at the top of the thermal storage tank.

Figure 2. The Fix. The aquastat needs to sense the water temperature at the top of the thermal storage tank.

Check out Details Matter in pdf form

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!