You Can't Make This Stuff Up

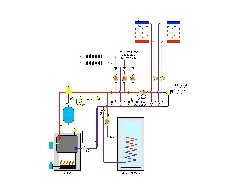

This month, rather than “synthesizing” an incorrect piping schematic, I’ll show you a system based on a sketch sent to me. This sketch is shown along with my “interpretation” using standard schematic symbols.

The Glitch

My speculation is that this system uses higher temperature plateless staple up radiant floor heating along with three zones of baseboard.Exercise: Look over the sketch and my interpretation of it. Then make a list of what you would recommend changing.

The Fix

Although I can only speculate on the design intent, this system contains several piping details that should be avoided.1. If the intent of the boiler bypass was to prevent sustained flue gas condensation the installer will discover this doesn’t work. The only assured way of preventing sustained flue gas condensation is to measure boiler inlet temperature and partially restrict hot water flow to low temperature load when necessary. If we assume all the loads including the radiant panel circuits are high temperature loads there really is no need for the bypass.

2. The “bullhead tee” at the top of the main boiler supply pipe is not a good detail. The turbulence it creates causes significant head loss as well as flow noise.

3. The zone circulators and flow checks should be located on the supply size of the zones to minimize heat migration. Since no expansion tank is shown there is no way of knowing whether the circulators are attempting to “suck” rather than push flow through the zone circuits.

4. My preference would be to use a zone circulator rather than zone valve for the indirect water heater. This will result in higher coil flow rates and higher rates of heat transfer. I would also suggest operating the indirect water heater as a priority load.

5. When zone valves are used in combination with a fixed speed circulator a differential pressure bypass valve should be used.

6. Apparently the designer didn’t see a need to install an air separator or purging valves. I have no clue how he expects to get the water in or the air out at start-up. I would certainly recommend a make-up water system, central air separator, and purging valves.

7. Indirect water heaters with vertical coils should be piped for counterflow heat transfer (hot water supplied to top of coil).

Visit www.HydronicPros.com for further information.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!