Installing check valves in a recirculation system

The direction of flow.

I had an interesting discussion recently about the use of check valves. One plumbing contractor commented that most plumbers don’t know how and where to install check valves. I countered with, “Shouldn’t the engineer designing the system tell the plumbing contractor where the check valves must be installed?”

His response was very appropriate: “What about single-family dwellings?” Touche! What about single-family dwellings? For that matter, what about any water distribution system? When and where do we install check valves?

The conversation regarding check valves all centered around hot water recirculation systems, so let me limit this review to those systems.

One contractor’s opinion was that anytime you have a recirculation system, you need a check valve. Another contractor said, “I use positive displacement pumps, so you can eliminate the check valves.”

Being the instigator that I am, I asked, “How many check valves should there be on a hot water recirculation system and where do you install them?”

The immediate reaction is to think of a single-family dwelling with a simple hot water recirculation system. However, when you get into larger commercial buildings, there are many zones, hence, many check valves.

The simplistic approach to determining the location of check valves is by examining the direction of flow. We all know what direction of flow we want in a piping system. If the water in the piping system always went in that direction, we would never need a check valve. However, plumbing water distribution systems are never that simple; rarely does the water always go in the direction we would like.

It comes down to analyzing the pressure differentials that can occur in a piping system. If a fixture is opened to flow water, the pressure in the line is instantly lowered. Pressure is the energy that moves water through the piping. If you run out of pressure, the flow stops. Pretty simple philosophy.

If you have two water lines intersecting, the flow is always going to go from high pressure to low pressure. Hence, in a recirculating system, the hot water being pumped through the piping always tends to have a higher pressure than the return line to which it connects.

If the recirculation system connects to the cold water supply to the water heater, the water can reverse course and go into the cold water supply. If a faucet or fixture is opened to only flow the cold water, the hot recirculating water will flow into the cold water. Hence, hot water will come out of the cold water faucet. This phenomenon doesn’t last long. As soon as the pressures equalize, the cold water again begins to flow out of the faucet.

But who wants hot water out of a faucet before they get the cold water?

In that same situation, if the recirculation pump is off and someone opens the hot water faucet near the intersection, cold water will come out and probably continue to come out of the faucet. That is because the pressure differentials allow the cold water to flow to the fixture rather than the hot water. In this example, hot water may not come out of the faucet until the recirculation pump turns back on.

What was just described is an installation where two check valves are necessary: one on the cold water supply to the water heater before the connection of the recirculating piping, and the other on the recirculating piping after the last connection of a hot water fixture. Without two check valves, the system will not work properly.

Some plumbing contractors have told me they can eliminate the check valve on the recirculating piping by running the pump 24/7. It is true that if the pump is always running, you may never need the second check valve. However, the energy codes no longer allow recirculating pumps to run continuously. They are required to be controlled with a shutdown period.

The other problem is you could have an overwhelming demand for hot water in the piping system. Then the pump’s small increase in pressure is lost by a hot water demand greater than anticipated. In that situation, the cold water will still flow in reverse and come out some of the hot water faucets. The ideal situation is still to install a check valve on the recirculating piping.

In analyzing this piping layout, it was easy to see where check valves were needed by looking at the direction of flow and possible direction of flow. Check valves make sure that water only goes in the direction of flow we want.

Check valve vs. flow control

When we get into a more complex system, there may be multiple zones in the hot water distribution system. Whenever a zone connects to the main piping in the recirculation system, a check valve is required. A proper design will have a flow control valve installed at the end of the zone to regulate how much water goes through that zone. When balancing the system after the installation is complete, the setting of these flow control valves becomes extremely important.

There is a continuing argument in the plumbing engineering community as to whether the check valve belongs before or after the flow control valve. The reason given for having the check valve before the flow control valve is because the flow control valve can be set up with the pressure drop across the check valve already considered.

The reason given for installing the check valve downstream of the flow control valve is to prevent the flow control valve from being subjected to possible swings in pressure or reversals of water flow.

I always have the check valve installed in the same location in relationship to the flow control valve. But I’m not going to say how I do it, so as to not offend those who follow the opposite point of view.

If you think you only need a flow control valve and not a check valve, I can take you to many buildings where the hot water recirculation system failed. It is easier to install the check valve when the system is being installed, as opposed to dealing with lawsuits and installing check valves after the building is up and running.

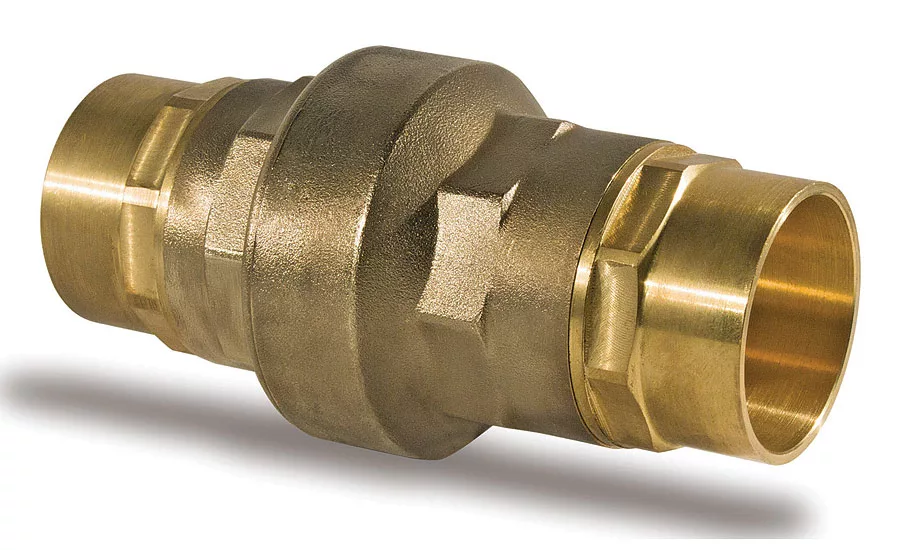

To be clear, I’m only speaking about spring-loaded check valves. I do not like swing checks in plumbing water distribution systems, ever! But that’s a subject of another column.

This article was originally titled “The direction of flow” in the June 2016 print edition of Plumbing & Mechanical.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!