Plumbing Essentials — Design Approaches, Codes and Everything in Between | Lowell Manalo

Building type is a key factor in the decision-making process

Vertical or horizontal piping distribution?

Images courtesy of the author.

The design of plumbing systems in buildings requires careful selection of vertical or horizontal piping distribution. Each option has its benefits and drawbacks, affecting the cost, efficiency and performance of the system. How do you decide which one to use? The building type is a key factor in this decision. Moreover, as I discussed in my previous columns, designers and engineers must follow the relevant codes and standards, sometimes the choice is already made for us.

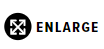

Vertical system distribution is the term used to describe the configuration of multiple risers in a building. These risers are pipes that connect the lower and upper floors of the structure and allow for the delivery of water, waste and vent, or other plumbing utilities. The main feature of vertical system distribution is that there are multiple risers, not just one. This means that each floor can have more than one source of supply. Vertical system distribution is different from vertical main risers, which are single pipes that run vertically through the building and branch out to each floor for horizontal distribution.

FIGURE 1

Figre 1: Vertical piping distribution.

Horizontal system distribution is the term for the pipes that run parallel to each floor level. These pipes connect to the main risers, which are the vertical pipes that supply water to the whole building.

There are advantages and disadvantages to both methods, depending on the size, shape and height of the building, as well as the energy efficiency, water conservation and maintenance requirements of the system.

Multilevel residential: Vertical distribution systems are more beneficial than horizontal systems for apartments and condominiums. They require fewer supports, hangers, inserts and other accessories for the pipes, and occupy less horizontal space in the ceiling. This simplifies the installation and reduces the coordination with other disciplines above the ceiling.

However, vertical distribution systems also have disadvantages. They can experience water hammer and thermal expansion problems, which can create noise, leaks and damage to the pipes and fittings. Moreover, vertical distribution systems may not be appropriate for buildings that have irregular shapes or layouts, or that have multiple branches or loops in the piping network.

Hospitals: One of the drawbacks of some old hospitals is that they have a vertical distribution system that serves each patient room floor. This may seem convenient, but it also limits flexibility. For example, if the third floor needs to be renovated, it will affect the other floors as well. This will cause the hospital to lose revenue and reduce its capacity to serve the community. Hospital codes and designers try to provide redundancies to avoid such impacts, but vertical systems are not flexible enough to support this. Although vertical distribution systems are not prohibited by codes or standards for hospitals, I advise against using them in new hospital buildings.

Laboratories: The unique work that takes place in labs requires designers and engineers to understand the codes and standards for this specific project type. Laboratories that fall under the National Institute of Health — Design Requirement Manual (DRM) standards, do not generally allow multiple individual risers for individual stacked areas. Risers cannot be used as the distribution approach to serve individual fixtures.

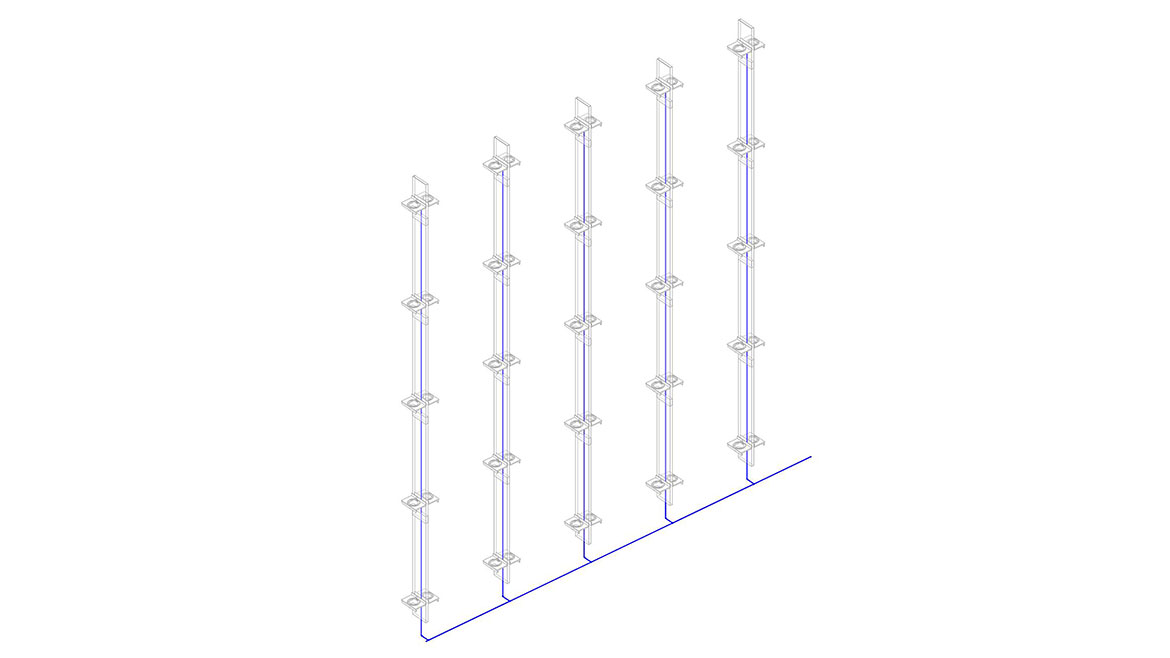

The DRM is considered the gold standard in laboratory design. Not only does it require horizontal distribution, but it also includes guidelines for specific location of the main risers. One example is that vertical risers should be located outside the laboratory space as much as possible and risers cannot be located behind individual fixtures, within partitions or any other manner that increases floor penetration within program space.

FIGURE 2

Figure 2: Horizontal piping distribution.

Horizontal distribution systems are more common in newer commercial buildings. Horizontal piping runs along each floor of the building, branching off to serve individual fixtures or groups of fixtures. They can also be easier to access and maintain since they are located on the same floor as the fixtures. In universities, laboratories, offices and similar structures, flexibility is crucial and normally requires horizontal distribution. Additionally, the main riser locations should be at construction elements that are permanently unaffected by interior fit-out arrangements, providing maximum flexibility for future modifications and connections. Isolation valves are also provided to facilitate independent shutdown at each floor, laboratory room, restrooms and other locations as required so that service and modifications may be performed without affecting other areas.

There are advantages and disadvantages to both methods, depending on the size, shape and height of the building, as well as the energy efficiency, water conservation and maintenance requirements of the system.

When choosing between vertical or horizontal distribution for plumbing systems, it is important to consider the characteristics of the building and the performance goals of the system. There is no one-size-fits-all solution, but rather a trade-off between various factors that affect the cost, quality and sustainability of the system.

Plumbing engineers and designers must carefully evaluate building characteristics, performance goals, and economic factors when choosing between vertical and horizontal distribution. A well-designed system ensures efficient water supply, drainage, and adaptability for future needs.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!