Hydronics Workshop | John Siegenthaler

Combining “low-tech” heating with state-of-the-art heat pump technology

Plan B

Image courtesy of Diane Labombarbe / iStock / Getty Images Plus. All other images courtesy of John Siegenthaler.

I live in rural upstate New York. There are lots of trees and many homeowners who harvest some of those trees for firewood. They fell them, buck them up into rounds using impressive Stihl or Husqvarna chainsaws, haul the rounds out of the woods in pickups or dump trailers, and use hydraulic splitters to slice them into cordwood. Many get their firewood a year before it’s needed to allow for proper drying.

Some, like me, burn their firewood in a wood stove that’s supplementary to other heat sources. Although we only burn about two face cords each winter, operating our stove on a cold cloudy winter day is something my wife and I enjoy. The warmth from a wood stove is delightful and relaxing. The stove also stands ready for heating or cooking when utility power is out, which seems to be a more frequent occurrence given our location and the status of local utility lines that were installed during the 1940s.

Some folks in my area “go big” with their approach to wood burning. They opt for whole-house heating sourced from an outdoor wood-fired hydronic heater, such as the one my neighbor has (see Figure 1).

FIGURE 1

I can’t describe these heat sources as outdoor wood-fired “boilers,” because they don’t hold their water in a pressurized vessel. Inside an outer shell made of steel roofing most of these units have a large water-tight welded steel box with a smaller welded steel box, suspended inside. The small box is the combustion chamber. The space between these boxes is filled with water. The fire within the smaller steel box transfers heat through its walls to the water. Most of these heaters have a circulator that shuttles water through insulated underground piping to some type of distribution system in the house. Figure 2 shows the generic internal construction for an outdoor wood-fired hydronic heater.

FIGURE 2

These heaters are not very efficient. Older models probably land somewhere between 30% to 45% efficient, depending on the moisture content of the wood and how the unit is operated. I’ve heard accounts of people burning upwards of 30 face cords of wood to keep their homes heated using these heaters. Anyone who has ever cut and split that much wood — on an annual basis — can appreciate how much work is involved.

Still, most of the people I know who own these outdoor wood-fired heaters are very devoted to them. They take pleasure in the fact that they’re not paying for much, if any, fuel oil or propane (natural gas is not available in our rural area). They’re proud of their independence from foreign fossil fuels. I get it, and admire their willingness to feed the beast to maintain their autonomy.

But there comes a time when even the best “Paul Bunyan” firewood enthusiasts start “feeling their age.” If you’re not sure what that term means, try cutting, splitting, moving and stacking 30 face cords of firewood. You’ll catch on quickly.

Which brings me to a recent inquiry from a fellow who had reached that point in life. He had installed and operated an outdoor wood-fired heater for years, and was really attached to it mentally, but becoming progressively less attached physically. He asked me how he could connect an air-to-water heat pump to keep the slab-on-grade floor heating system in his 5,000-square-foot shop warm. He wasn’t ready to completely part with the outdoor wood-fired heater, but wanted an option for those days when he chose not to use it.

Keeping it simple

His shop building had a well-designed floor heating system. Plenty of tubing, conservative circuit lengths, ample underside insulation and good manifolding. It would definitely be adaptable to the heat pump.

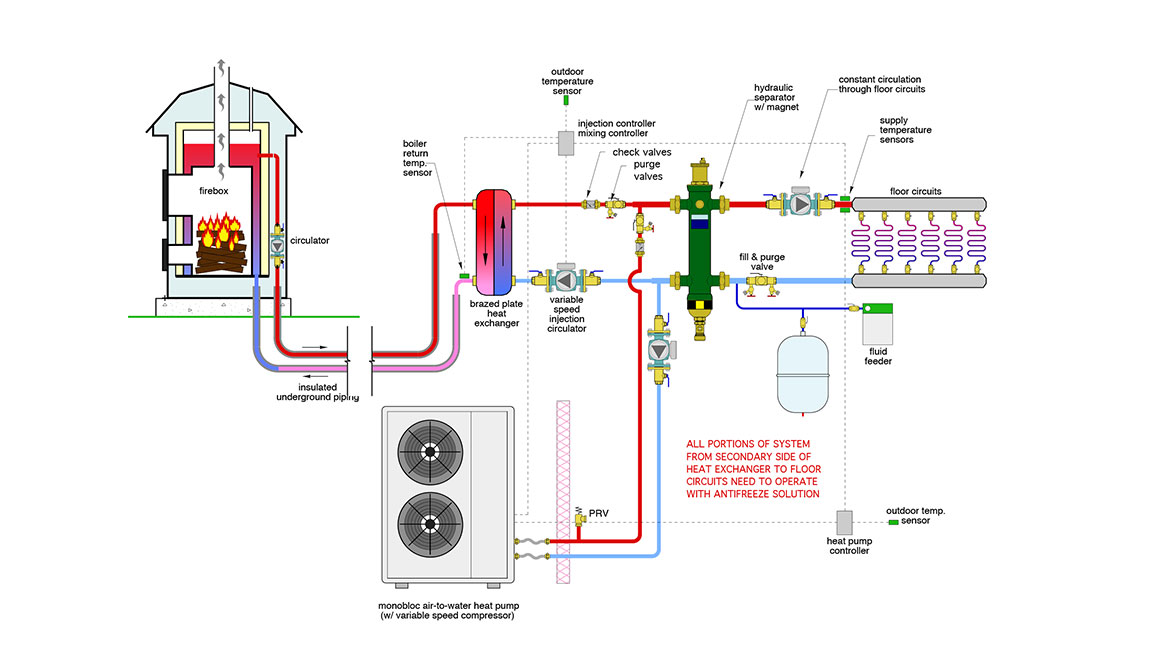

The concept I suggested is shown in Figure 3.

FIGURE 3

So how does this work?

Let’s start with wood-only mode. The owner needs to enable the circulator in the outdoor wood-fired heater whenever it is fired. This provides flow through the primary side of a generously sized brazed plate heat exchanger, which separates the open loop of the outdoor wood-fired heater from the remainder of the system, which is designed as closed loop.

The circulator between the heat exchanger and hydraulic separator operates at variable speed to inject heated fluid from the secondary side of the heat exchanger into the hydraulic separator. The injection rate is set by a controller that monitors the supply temperature to the floor circuits. The higher the injection rate, the warmer the supply temperature to the floor circuits. The target supply temperature is determined based on outdoor reset control. This allows the temperature supplied by the outdoor wood-fired heater to “coast” to the lowest possible value that can still satisfy the heating load of the building.

The distribution circulator runs continuously during the heating season. I like to use continuous circulation in garage and shop buildings that have overhead doors. It helps even out heat delivery across the floor and minimizes the potential for cold spots just inside the overhead doors. The hydraulic separator in this system makes this an easy detail.

The monobloc air-to-water heat pump is connected in parallel with the heat exchanger. It can operate as the sole heat source, primary heat source, or supplemental heat source. The system controls determine the assigned function of the heat pump.

If the heat pump is intended to be the supplemental heat source, a 2-stage room thermostat could be used. The first stage would be to enable the injection mixing controller. If there’s sufficient heat in the wood-fired heater, the thermostat’s second stage would not activate. If the wood-fired heater was off, or too cool to maintain the set indoor temperature, the thermostat’s second stage would enable the heat pump.

Many modern air-to-water heat pumps can monitor a supply temperature sensor, either directly or through an interfacing controller. The variable speed compressor in the heat pump can adjust as necessary to keep the supply water temperature to the floor circuits at some target value based on outdoor reset.

Prevent heat dumping

One situation that must be avoided is inadvertently allowing the injection circulator to operate when the heat pump is the sole heat source, and the outdoor wood-fired heater is cold. Doing so would shuttle heat sourced from the heat pump through the outdoor heater, needlessly dissipating it to the outside or into the soil surrounding the underground piping.

This detail is handled by using the boiler inlet temperature sensor on the injection controller. That sensor is mounted on the primary side of the heat exchanger. If the injection mixing controller is active, it monitors this sensor and slows down or stops the injection circulator when it’s below some set minimum, such as 80° F. Thus, if the outdoor heater is cool or cold, and fluid is still circulating through the primary side of the heat exchanger, the injection circulator will remain off, even though there’s a call for space heating.

If the injection controller didn’t have this ability, there’s a workaround. Install a differential temperature controller that compares the water temperature entering the primary side of the heat exchanger from the wood-fired heater, to the temperature on the return side of the floor circuits (e.g., entering the lower right side connection on the hydraulic separator). If the temperature entering the primary side of the heat exchanger is 5° F or more above the return temperature from the floor circuits, allow the injection mixing controller to operate. If this temperature difference is less than or equal to 3° F, do not allow the injection mixing controller to operate.

The closed-loop portions of the system would operate with an antifreeze solution. This is necessary to protect the monobloc heat pump from freezing.

Another option

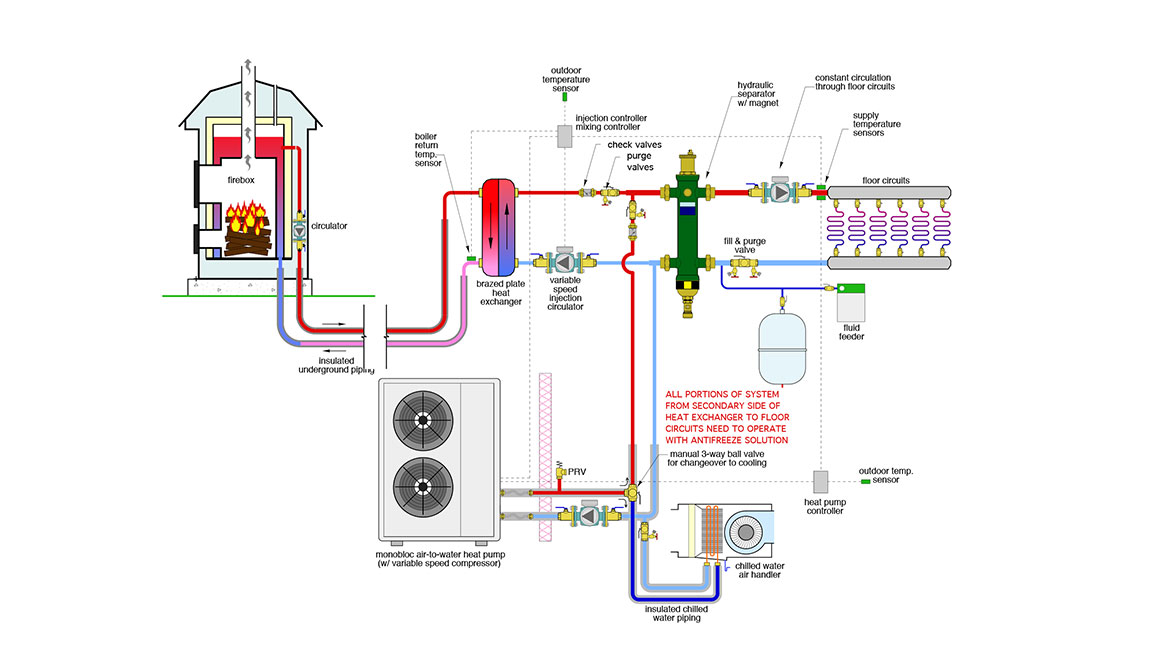

Although it may or may not be used, the heat pump has a reversing valve allowing it to operate as a chiller. If the owner wants to add cooling to the shop, it’s just a matter of installing a diverter valve (manual or motorized) that can direct flow from the heat pump to a suitable chilled water air handler. I’ve shown the concept in Figure 4.

FIGURE 4

Any piping carrying chilled fluid must be insulated and vapor sealed. Also note that the diverter valve, in this case a 3-way manually-operated ball valve, is only used on the pipe carrying fluid out of the heat pump. The other pipe leads back to the system to provide “communication” with the expansion tank.

The heat pump controls would be set for a desired leaving chilled water temperature, typically 45° to 50° F. The compressor speed modulates as necessary to maintain that setpoint temperature.

Wood and Watts

This application demonstrates that what might be perceived as “low tech” heating (e.g., burning wood in an outdoor heater) can be combined with a state-of-the-art heat pump using off-the-shelf hardware to keep a shop comfortable though the winter - and maybe even through the summer…

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!