Boilers offer path to greener future

More electric boiler options entering the market.

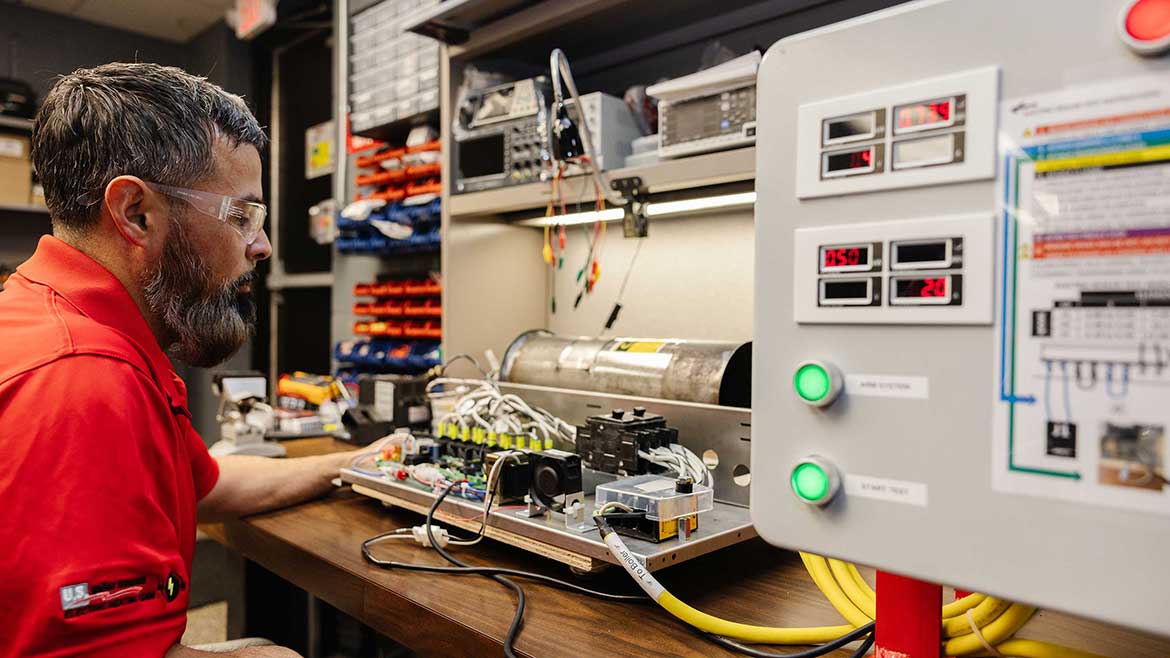

Charlie Kopplin, director of marketing for HSSC, representing U.S. Boiler Co., notes that the most recent trend facing the market has been the proliferation of electric boilers. Photos courtesy of Lochinvar, NextGen Boiler and U.S. Boiler.

As federal, state and local governments place an increased focus on a decarbonized future, the quest for energy efficiency and sustainability has become more critical than ever. While electrification can certainly help meet the decarbonization goals, high-efficiency condensing boilers are also a possible solution to bridge the gap between where we are now and where we are heading.

“Laars Heating Systems has expanded its higher efficiency, condensing boiler offerings over the past few years,” says Chuck O’Donnell, director of marketing for Laars Heating Systems. “This has largely been driven by increased customer demand, especially noting the ease of replacement from older, less efficient boilers to our new high-efficiency designs. The availability of incentives has also contributed to the increase in demand. Gas-fired boiler combustion technology has advanced, resulting in high-efficiency levels and low NOx emissions, minimizing impact to the environment. Electric residential boilers, as well as boilers that can work in systems with heat pumps as a “hybrid” system, are growing in popularity, as well. However, homeowners should confirm that heat pump-based systems can operate reliably while handling their heating load in cold climates. High efficiency boilers will continue to be needed to help bridge the gap between the current state and an electrified future.”

The NextGen Electric Boiler is engineered with all components in one plug-and-play unit, enabling the contractor to perform a consistent and professional install for radiant heating applications.

Sustainability and energy efficiency are the main drivers when it comes to product development, according to Dan Rettig, senior product manager, heat pump water heaters and sustainability, for Lochinvar.

“Since boilers already deliver 95% AFUE or higher, the industry is shifting its focus to innovative features that allow boilers to run more efficiently,” he explains. “For example, we are starting to see gas-adaptive technology in the industry, where customers can hook up either natural gas or liquid propane to the unit and it will self-adjust.”

Rettig notes that more and more homeowners are investigating mono block air-to-water heat pump water heaters as a viable alternative because of the attractive incentives and rebates in some regions. “Heat pumps are a smart choice for homes that currently have a high-efficiency gas boiler. But there are still a lot of non-condensing boilers being sold. Older homes often require warmer water temperatures due to older radiators, which require warmer water temperatures to produce the required Btu output. This can make it difficult to switch to a heat pump or condensing boiler, which is why it’s important that we continue to develop non-condensing boiler technologies as well.”

The Ambient Electric Boiler weighs 54 pounds and features connections to the heat exchanger on top, meaning that the system does not need to be drained in order to service the element.

Demand grows for electric boilers

Charlie Kopplin, director of marketing for HSSC, representing U.S. Boiler Co., notes that the most recent trend facing the market has been the proliferation of electric boilers.

“While the electric boiler market is relatively small, sales of electric boilers and heat pumps have seen the largest percentage of growth,” Kopplin explains. “Electric boilers are designed to operate near 100% efficiency, with natural gas condensing boilers near 95%,” he says. “If a user’s electricity is generated from renewable sources, heat pumps and electric boilers can be a very environmentally-friendly option. In some areas, electricity prices have declined to a point where consumers can see an economic case for converting from fossil fuel heating to electric. We view it as a long-term trend that everyone in the industry needs to pay attention to. State incentives appear to be getting a lot of attention with contractors and consumers; manufacturers are gearing up to meet potential demand. But manufacturers, contractors and consumers are still learning about the technology and economic challenges involved with the transition. While the path to convert every building and home to electric heat is unclear, Burnham intends to forge a path rather than watch from the sidelines.”

Todd Seed, strategic account rep for NextGen Boiler, explains the demand for electric boilers is gaining ground, partly due to the fact there is no venting needed in an electric solution.

“Even the most efficient gas or oil boiler still needs venting, which leads to inefficiencies,” Seed says. “Certain areas of the country are starting to outlaw fossil fuels for new construction. New York City, Colorado, Massachusetts and other areas — they’re starting to tax the hookup for fossil fuels, so people are looking for alternative solutions. And radiant heating and water heat solutions are not going away. More than ever, there are more luxury homes being built than ever before, and what’s more comfortable than nice warm floors? When they can’t put in a gas boiler, they’re turning to electric solutions.”

LEFT: U.S. Boiler's new Ambient Electric Boiler is an ultra-compact, wall-hung boiler is available in three capacities: 16, 20 and 24 kW, or 54,600, 68,200, and 82,000 Btu/h, respectively. Supply water temperatures between 90° F and 180° F can be provided, using field-proven electric elements. RIGHT: A U.S. Boiler Co. employee works in the Ambient Lab.

Seed notes there is also a lot more “green education” going on. “More people are being informed — look at the trend for electric vehicles. How many people are out on the road driving EVs today? If you had asked them all 10 years ago if they would be doing that, they would have said, ‘No.’ Now, it is a viable option and it's a good viable option for a lot of consumers.”

O’Donnell notes that the transition to electrification must be carefully managed to ensure that more emissions are not generated as a result, and that the grid has the capacity to meet the increased demand.

“There is a clear demand for electric boilers both residentially and commercially,” he notes. “Many factors result in this demand, including low electric costs in localities where there is a large percentage of renewable electricity; installation costs in some cases can be less than equivalent combustion equipment; the elimination of the need for gas, propane, or oil delivery systems; flue gas venting and fresh air ducting is not required; and potential reduction in maintenance requirements vs. combustion equipment.”

Advantages vs. disadvantages of electric

O’Donnell points to the main advantage to using an electric boiler vs. using natural gas, is eliminating the need for a gas hook-up to be run into a home, or if using oil or propane, eliminating the need for an oil or propane tank to be placed on the premises.

“Also, the need for venting flue gases is removed along with the need for fresh air intake to the boiler,” he explains. “Maintenance needs on electric boilers tend to be less than those associated with combustion equipment. Electric boilers also are ‘renewable energy ready’ for when a local utility increases the percent of renewable used in their grid. A homeowner using an electric boiler can also consider the addition of solar panels to help power the boiler, further reducing their carbon footprint.”

On the flip side, choosing an electric boiler may need a larger power service to be installed in the home, O’Donnell points out.

The NextGen Modulating Electric Boiler is available in 4 kW, 6 kW, 8 kW, 12 kW and 14.4 kW sizes.

“Gas-fired boilers tend to be less expensive to operate — in some cases, much less expensive — depending on electric utility costs, and gas-fired boilers can have a smaller carbon footprint than electric boilers depending how the electricity in a homeowner’s area is produced,” he says. “There are also many gas- and oil-fired boiler designs available to the homeowner with trained technicians easily reachable for installation or service needs. There are fewer electric boilers to select from with fewer trained technicians available.”

Kopplin notes that electric boilers are relatively simple machines that deliver predictable efficiencies so there are not many surprises when properly installed and maintained.

“Electric boilers can easily replace most fossil fuel boilers with minimal changes to the remainder of the heating system,” he says. “Customers should be mindful of the cost of making electric service upgrades to their home and account for the reliability of that electric service. In the case of a power outage, fossil fuel boilers can continue to generate heat with a backup generator, while electric boilers typically require too much electric power to enable that.”

Seed notes the biggest obstacle the electric market faces is overcoming the ‘old-school mindset’ that fossil fuels are cheaper.

“As we know, this is not at all true — in many cases, we continue to see fossil fuel costs increase faster than electricity in many regions,” he says. “The performance of electric boilers is very comparable to traditional gas or oil-based systems. Two advantages are you no longer need to vent an electric boiler or need gas to be piped to the residence. It’s a great solution for any suburban customer that is not on a natural gas line.”

As far as having the proper electrical system in the homes, Seed notes that NextGen boiler has been reaching out to influence builders and encourage municipalities whenever possible to increase the electrical entrance and bring the amperage up to modern day levels.

Rettig notes that the option of choosing between natural gas and electric is really a site-by-site evaluation based on the cost-effectiveness and whether the site can handle the electric load.

“It’s also dependent on state and local regulations, as some regions of the country are not allowing gas lines or LP tanks in new construction, which also drives the push for electrification,” he says. “On the flip side it can sometimes be difficult to retrofit an existing home from gas to electric, which is why high efficiency boilers remain incredibly important to the industry’s sustainability movement.

“At the end of the day, you are reducing your carbon footprint any time you switch to a higher efficiency boiler,” Rettig continues. “When you shift away from gas products, you are also inherently reducing the carbon footprint on site. It’s important that we look at the best ways to reduce carbon output while also making it easy and affordable for homeowners to adopt high efficiency gas technologies. When a unit operates at a higher efficiency, they have improved emissions quality from the combustion process. Going from an 80% efficiency product to a 96% efficiency unit, there is a reduction of carbon emissions — undoubtedly supporting decarbonization goals.”

Lochinvar’s Rettig notes it can sometimes be difficult to retrofit existing homes from gas to electric, which is why high efficiency boilers remain important to the industry’s sustainability movement.

The future of electrification

According to O’Donnell, LAARS foresees a plateau in the adoption rate of electrified appliances and vehicles due to the current limitations of North American electrical infrastructure.

“Simply put, the current infrastructure cannot handle the full electrification of HVAC, water heating, vehicles, outdoor home maintenance equipment, etc. without significant financial investment that will take years to deploy,” he notes. “There is runway between the current state and when that plateau is reached where many electrically based pieces of heating equipment will be installed. However, combustion equipment will continue to serve a critical role to heat our homes, businesses, schools, etc. for years to come. That is why Laars is investing in both high-efficiency combustion-based heating equipment and electrically based heating equipment, along with the next generation of cold climate ready heat pump technology.”

Rettig notes that Lochinvar is excited about the future of electrification, and its engineers and R&D teams are working hard to support the push.

“To make testing easier, we’ve expanded the electrical infrastructure and added environmental chambers at our main facility in Lebanon, Tennessee,” he says. “We enjoy the challenge of developing technology to meet the decarbonization goals of the industry and our customers.

“The growth of the boiler market has been fairly consistent in recent years, and we know that customers are ready to take advantage of high efficiency products,” Rettig adds. “But as we look forward, we anticipate a decline in the demand for non-condensing products as the market moves toward higher efficiency condensing products and heat pumps.”

The HVAC industry is only one component in meeting overall carbon reduction targets, Kopplin notes. “In developing our electric product portfolio, we’ve learned that just about every home and building can reduce emissions by replacing or supplementing its hydronic heating system with electric boilers or heat pumps. The most significant factors hindering the transition are increasing the amount of reliable electricity in homes and buildings, economic barriers to replacing or supplementing current systems, and the market’s confidence in the technology. While it will be subject to changes in governmental administration and the ebbs and flows of state incentive programs, we’re confident there will be growth in electric heating.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!