John Siegenthaler: Heat recovery helper

Offer a total HVAC solution.

Ievgenii Gorun / Creatas Video+ / Getty Images Plus

As building codes and programs such as Energy Star and Passive House require higher degrees of air sealing in new construction, the use of heat recovery ventilation (HRV) is increasing. A wide range of HRV products are now available for residential and commercial applications.

Fundamentally, an HRV is an air-to-air heat exchanger. During winter, an incoming stream of cold outside air passes through the heat exchanger core of the HRV where it absorbs heat from the outgoing (but warm) air stream. The amount of heat recovered depends on the temperature differences, but recovery efficiencies in the range of 70% are often cited by HRV manufacturers.

In Northern climates, where the incoming air stream can be below 0° F, a 70% heat recovery efficiency still leaves the fresh air stream supplied to the building well below normal room temperature. For example, recovering 70% of the heat from an exhaust air stream coming into the HRV at 70° F, would still only warm -10° F incoming air to about 46° F (assuming equal air flow rates and 100% sensible heat transfer). That’s on the cool side when introduced into normal occupied spaces during heating months.

Hydronic solution

This situation presents a unique opportunity to use hydronic technology, along with a geothermal water-to-water heat pump, or an air-to-water heat pump, to improve comfort as well as offer a total HVAC solution for space heating, cooling, domestic water heating and ventilation.

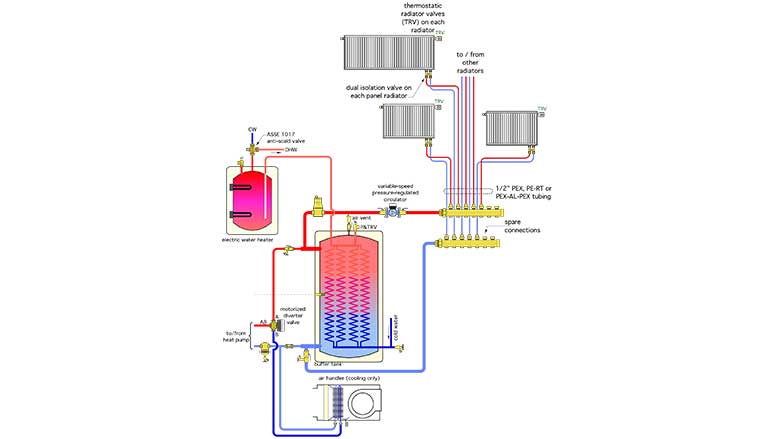

Take a look at the system in Figure 1.

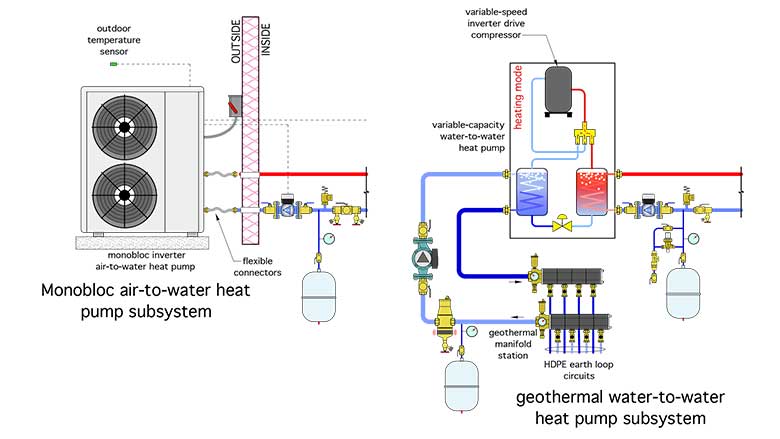

This system uses a “reverse indirect” tank as a buffer tank and domestic water “preheater.” Heat is supplied to the tank from an air-to-water heat pump, a geothermal water-to-water heat pump or even an auxiliary boiler. Potential configurations for both heat pump options are shown in Figure 2.

When a monobloc air-to-water heat pump is used, the entire system would operate with an antifreeze solution. If the air-to-water heat pump was a split system, no antifreeze would be required.

The heat pump would supply heated water to the buffer tank year-round. The principal load for this heated water is space heating. The secondary load is domestic water preheating, and thus the need to maintain the buffer tank in a heated state year-round.

Cooling is provided by a chilled water coil in an air handler. The motorized diverter valve shown in Figure 1 directs the chilled water to the coil during cooling, and back to the buffer tank when its temperature needs to be “topped off.”

Because both loads could potentially call for operation at the same time during summer, a control priority needs to be established. Typically, that priority is maintaining the buffer tank for domestic water heating. Cooling is temporarily interrupted to maintain the buffer tank temperature and then restarted once the tank is up to temperature. The temporary shedding of the cooling load typically only requires a few minutes, during which the blower in the air handler can remain on if desired.

Back to ventilation

The ducting system for the air handler is sized to provide a nominal 400 cfm per ton of cooling. As such, it’s very capable of delivering the lower ventilation airflow, nominally 15 cfm per person. The fresh (preheated) air just needs to be injected into the return side of the air handler.

Although the air handler could operate at the higher airflow rate 24/7 for ventilation air delivery, doing so wastes energy due to higher than necessary airflow. Modern air handlers typically use ECM blower motors that can be programmed to operate over a wide speed range. For example, during a ventilation-only mode, the blower in some air handlers can be dialed back to about 150 cfm. When cooling is operating, the blower could operate at 400 cfm per ton (e.g., 1200 cfm nominal for 3 tons of cooling). It’s best to check with specific manufacturers for how this can be accomplished. It may be as simple as a firmware change, combined with multiple-speed tap wiring to the motor.

Booster mode

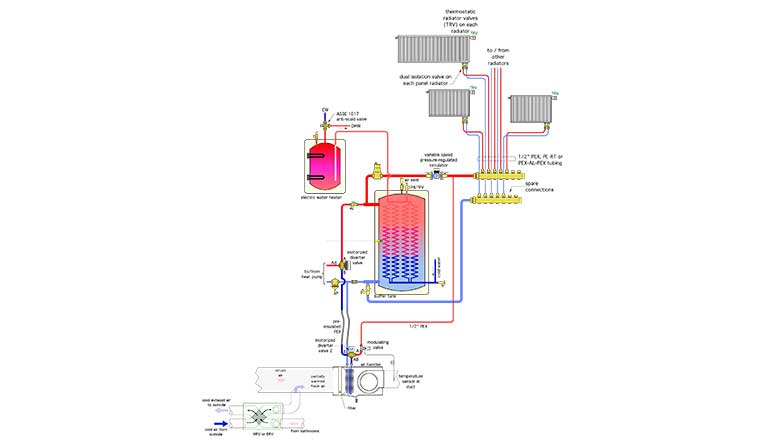

Since the air handler can deliver ventilation airflow year-round, its coil can be used to bring the partially heated fresh air stream up to a room-neutral delivery temperature. One piping method for doing this is shown in Figure 3.

The air handler in this configuration can operate in one of three modes: Ventilation-only mode; Cooling plus ventilation mode; or Ventilation plus boost mode.

For ventilation-only mode, the blower in the air handler should provide an airflow rate just above that of the HRV.

During cooling mode, the blower speed would be set to about 400 cfm of airflow per ton of cooling capacity.

The ventilation plus boost mode is intended for times when outdoor temperatures are cold. The intent is not to heat the building with the ventilation air, it’s to introduce fresh air into living spaces at about the same temperature as those spaces. Under these conditions, it’s possible to pass warm water from the buffer tank through the air handler’s coil to boost the temperature of the ventilation air prior to introducing it to the occupied space. A modulating 2-way thermostatic valve is used to regulate the flow of warm fluid through the coil. The flow rate through that valve — and the coil — is controlled based on maintaining a set supply air temperature on the outlet side of the air handler.

A word of caution is in order. If the system is located where outdoor temperatures are well below freezing much of the winter, the coil in the air handler needs to be protected against freezing. That’s “automatic” with the monobloc air-to-water heat pump system shown in Figure 1 because the entire system operates with a 30% solution of propylene glycol. If the system operates with water some type of failsafe control would be needed to automatically turn off the HRV if the coil in the air handler approached a potential freezing condition.

Offer it all

The longstanding “stigma” that hydronic systems can’t provide cooling is waning as air-to-water and geothermal water-to-water heat pumps gain market share against boilers. This sets the stage for progressive hydronic professionals to offer heating, domestic hot water and cooling. Why not extend this even further to include heat recovery ventilation? The market for this type of “total HVAC solution” is quickly developing.

Figures courtesy of John Siegenthaler.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!