Wall-hung condensing boiler saves space and energy

Combi-boiler offers plumbing and heating solution for Pennsylvania home.

When a Pennsylvania homeowner was looking for a dependable heating solution to take up less space, J. Golden Plumbing, Heating and Cooling found the solution in the wall-hung Brute FT.

When a Pennsylvania homeowner was looking for a dependable heating solution to take up less space, J. Golden Plumbing, Heating and Cooling found the solution in the wall-hung Brute FT.

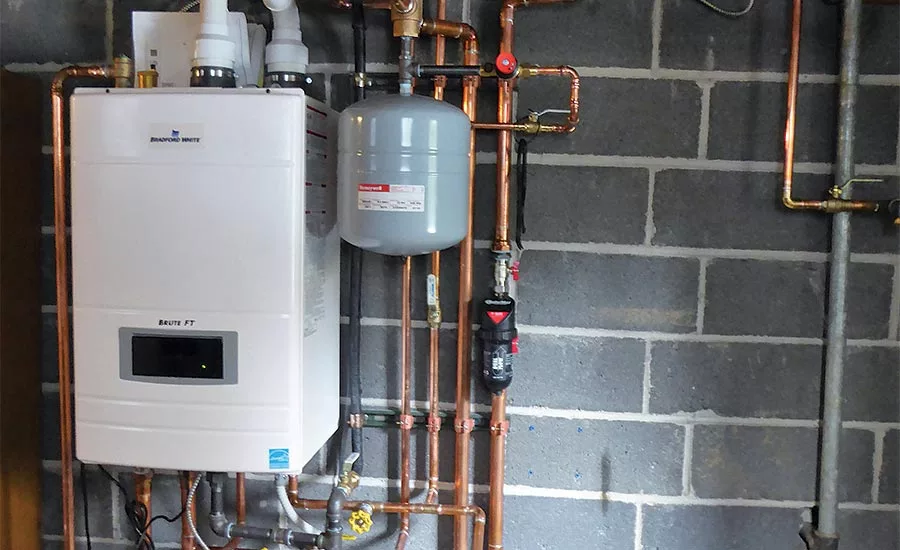

J. Golden Plumbing Heating Cooling installed a Bradford White Brute FT wall-mounted combi-boiler to serve the approximately 2,200-2,300-square foot multi-story house.

Jason Golden, owner of J. Golden Plumbing, Heating and Cooling; Tom Kelly, technical sales representative — specialty products at Bradford White; and Jim French, director of sales — specialty products at Bradford White, on the job site.

When a customer in suburban Philadelphia called Jason Golden, owner of J. Golden Plumbing Heating Cooling in Perkiomenville, Pennsylvania, for a plumbing and heating retrofit, Golden had a solution that delighted the customer in a couple ways.

“The customer had a 30-year-old chimney-vent gas boiler with an electric water heater serving as a hot water backup,” says Golden, who’s been in the trade for 22 years and running his own shop for five. “We were brought in to see what we could do to modernize the system. He also had an issue where his chimney was becoming old and needed some work, as well as the water heater being due for replacement. And they were also looking to free up some storage space down in the mechanical room, so we kind of killed a bunch of birds with one stone by going with a wall-hung combi-boiler. And that allowed us to eliminate extensive chimney work and the electric water heater, as well.”

The house was of older vintage, approximately 2,200-2,300 square feet in three stories, with copper tube baseboard. The homeowner was looking for energy savings, and he was also looking to free up some space in the basement that was dominated by a 3-foot x 3-foot x 3-foot behemoth of a boiler, a water heater and a tangle of pipes and wiring.

“They valued storage space,” Golden relates. “I mean, for most of our customers, storage is a premium these days. One of the benefits of installing wall-hung boilers is, obviously, we keep it up off the floor, we buy the customer more usable space in the house. It declutters things, such as low-hanging pipes and circulators because all that stuff is now moved over to the wall. We take away that 50-gallon tank water heater and replace it with the combi boiler. Plus, there’s the chimney repair that we would have to do if we kept a chimney-mounted boiler in place.”

The solution

Golden opted for a Bradford White Brute FT wall-mounted combi-boiler with a 95% AFUE. The boiler has a low pressure drop fire-tube stainless steel heat exchanger design with finned aluminum core fire tubes, sealed combustion chamber, pre-mix ceramic fiber burner and welded construction. It meets low NOx requirements at 17 ppm. It may be vented horizontally or vertically to lengths up to 100 equivalent feet. The Brute FT also features an ASME “H” stamp, 30 psi (207kPa) ASME pressure relief valve, gas leak detection, a boiler pump wired and mounted inside jacket and a built-in condensate trap and drain. It can be vented with PVC, CPVC or Polypropolene, and works with natural gas or propane configurations.

Space-saving advantages

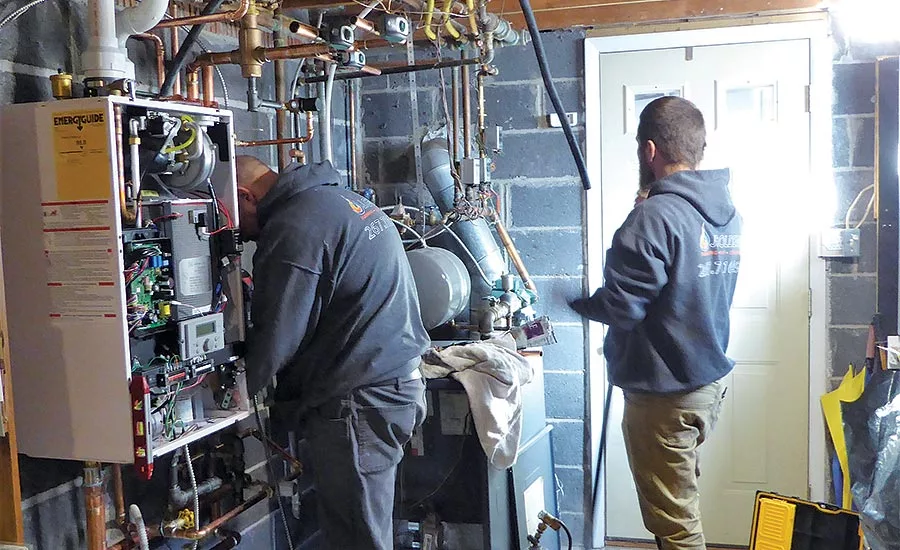

Golden says the project was not hugely challenging, with the biggest issue being organizing all of the pipes, circulators and wiring from the old boiler and water heater and moving everything over to the wall. It was actually more challenging to get the old boiler, which weighed roughly 450 pounds, out of the house, he says. When customers see the difference in the space the wall-hung boiler occupies, that helps sell the job almost as much as the energy savings, Golden explains.

The jobsite was only about a half hour away from Bradford White’s headquarters in Ambler, Pennsylvania, so representatives from the factory came out and offered insights and best practices into settings and operating parameters when firing up the unit. Golden says Bradford White has been responsive, and that it’s easy to get technical support over the phone. Their local manufacturer’s representative in southeast Pennsylvania has an excellent track record on being responsive with repair parts and technical service.

That kind of support from manufacturers is important to Golden because, “the customer wants to know what we can do for them and we can assure the customer that they are in good hands.”

Installation ease

The installation time of the Brute FT is about the same as any other wall-hung boiler, Golden says. The installation is streamlined if the contractor orders the primary/secondary header that goes with the boiler. It takes more time if the wall-hung boiler is replacing a cast iron floor-mounted chimney-vented boiler because converting the piping and wiring to hang it on the wall takes longer.

When it came to the unit’s controls system, Golden says he found it to be intuitive, and he liked its ability to be customized for each house to account for the difference between fin tube radiators and cast iron.

The move to wall-hung condensing boilers is a slow but definite trend in his sales territory, Golden says, that will require more customer education. He installed the boiler back in January, so he doesn’t have a full year of energy bill information yet, although he expects it to be substantial. Customers increasingly are seeing the value of the energy savings they can get from high efficiency equipment, plus energy costs keep going up, he points out. Customers quickly become converts when they see the difference in the energy bills between an 80% efficient boiler and a 95% efficient condensing boiler. It makes for both happy customers and happy contractors.

Wall-hung boilers offer many options for home owners, Golden notes.

“Where they really excel is in a home with radiant heat,” he says. “That would be the biggest trend, when customers decide to go with radiant floor heat.

We’re always trying to push them towards a wall-hung condensing boiler because that’s where they really excel. Another good application would be larger homes with multiple bathrooms or larger homes that have bathrooms with body spas or body sprays — things that use copious amounts of hot water — because wall-hung combi-boilers can generate domestic hot water for longer periods of time.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!