Legionella prevention, labor shortage top commercial plumbing trends

Industry collaboration is key to future success.

The Watts/Powers IntelliStation digital water mixing system delivers mixed hot water throughout a hot water recirculation loop in commercial and institutional facilities, ensuring ensuring safe and consistent water temperatures, which is important for Legionella prevention.

Variety is the spice of life. That proverb certainly holds true in the commercial plumbing industry thanks to many different product offerings and solutions available in today’s marketplace.

The fact is, customers want more choices, and projects are different and more complex than ever, notes Scott Brady, research and development manager at PRIER Products.

“Budgets, facilities, size of projects, uses and expectations are all different,” Brady says. “PRIER works very close with engineers, architects and contractors to understand trends and needs from the market. For example, we went from offering two hydrant box options to seven. And within those options, there are different product finishes, features, benefits and cost. This gives the building owner and contractor a variety of options for installation, aesthetics to match the building materials and price points in order to meet budget requirements.”

In addition, PRIER also understands the challenges in the field for the installer; the company has modified its products to speed up the installation process.

“We purposely design our products for the contractor, wholesaler and engineer,” adds Nick Manning, president of PRIER Products. “The features for contractors have evolved to become labor saving features, single hole design, easy installation features and product flexibility.”

Legionella and Other Pathogens

Legionella prevention is always at the top of the list when considering trends in the commercial plumbing market. According to the Center for Disease Control, in the United States, the rate of reported cases of Legionnaires’ disease has grown by nearly five and-a-half times since 2000. However, there are additional waterborne threats the industry needs to be aware of, notes Jana Summey, healthcare vertical market manager, Legionella & Waterborne Pathogens Connected, Watts Water Technologies.

“Legionella bacteria have certainly won their 15 seconds of fame; it seems as if they’re on every neon-lit marquis location, industry-wide,” she says.

“When planning how to combat legionella, experts should also consider other waterborne pathogens; each pathogen is unique. They will not all react to the same solutions in the same way. Some waterborne pathogens may have no reaction to certain chemicals. Sometimes they could even counteract each other.”

These other waterborne pathogens include: Vibrio cholera, Giardia, salmonella, Hepatitis A, E.Coli and more.

According to Summey, sophisticated electronic sensors — both wired and wireless — are increasingly being used in healthcare settings and for legionella risk mitigation.

“Sensors can be used to monitor and manage water temperature, disinfectant levels, water flow and more,” Summey says. “The data delivered from these sensors can have a considerable impact on a hospital’s water management plan, allowing a facility team to make informed decisions to continually adapt and improve their water management plan.”

Additionally, there has been emphasis in the plumbing industry over the past several years has been placed on conservation, and LEED certification. While these are admirable goals, they sometimes have unexpected consequences, Summey notes.

“Low flow design has been very popular as a way to improve water conservation,” she adds. “Though, now growing concerns about legionella and other waterborne pathogens, we are seeing that low flow fixtures can create environments that encourage bacteria and biofilm growth. More flow — and smarter flow — is making a comeback.”

Lack of Tradesmen and Women

The labor shortage and lack of young people entering the industry continues to be a challenge in the commercial plumbing market, according to Ed Smiley, director of Commercial HVAC Wholesale, Xylem. In fact, the Q4 2019 Commercial Construction Index dropped to its lowest point since 2017, according to the USG Corp. + U.S. Chamber of Commerce Commercial Construction Index. Per the report, 89% of contractors reported having at least a moderate level of difficulty finding skilled workers. As a result contractors are asking skilled workers to do more, are challenged to meet schedule requirements and are putting gin higher bids for projects.

“In many areas of the country, the labor shortage is economy driven,” says Smiley. “There are a number of projects in major cities on hold because overextended contractors have to finish one project before being able to move on to another.”

Bell & Gossett continues to utilize its Little Red Schoolhouse and the educational opportunities it presents to train the industry,” Smiley adds.

“Along with in-person instruction, the online materials available continue to grow and provide great training remotely,” he says. “Combining new pump technology with better sizing and selection tools improves system sizing and product selection, making it much easier to make the best equipment choices in an ever-changing industry.”

Contractors Weigh In

Kansas City, Missouri-based MMC Contractors specializes in building large, complex projects around the U.S. in healthcare, energy, mission critical, pharmaceutical, industrial and commercial markets.

“We’ve seen really good growth in the past year,” says Matthew West, plumbing superintendent and general foreman for MMC Contractors. “In fact, we’ve been extremely busy this winter, even when it typically slows down a bit. Almost all of our guys are busy on jobs right now. But we’re trying to stay ahead of the curve when it comes to a tightening labor market and shortage of new talent. We’ve been focused on attracting the next generation to the plumbing and mechanical trades; and working hard with schools in that effort.”

MMC is currently part of a 10-year project at Cerner Innovation Campus in Kansas City, which spans 290 acres. It consists of 4.7 million square feet of space in 16 buildings, including data centers, childcare and health clinic facilities, office, dining, hotel and retail space. When complete, more than 16,000 employees will call it home.

“We chose PRIER’s commercial product line for the first four office buildings due to the quality, warranty, engineering and technical support and proximity,” says West. “PRIER’s products are quick and easy to install, which reduces labor and project costs, and offer very high flow rates, attractive finishes, high-quality components and reliability.”

Kevin Walsh, executive vice president of plumbing and fire protection for Canton, Massachusetts-based E.M. Duggan, notes prefabrication as the biggest trend in the Boston-area market.

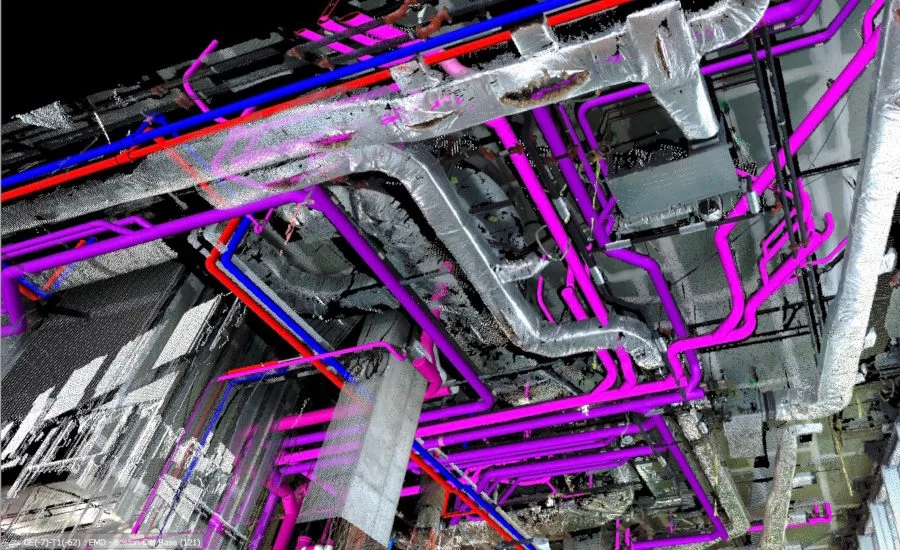

“Everybody is moving toward as much prefabrication as possible, but that all comes with a carrot being driven by Revit, AutoCAD and 3D modeling and being able to extract fabrication that is accurate,” says Walsh. “We’re using Revit primarily. What happens is, we draw our mechanical systems into that model, and then from there, we’re able to extract it and prefabricate the whole building.

“Speed and cost are the main drivers because owners want their buildings immediately,” he continues. “We want to deliver them as quickly as possible, but we need to be as accurate as possible. I mean, one of the biggest trends right now is that the owner and the developer really don’t want to pay for a full blown design. So, in turn, they put that onto the subcontractor. I would say that is also very much a growing trend in the industry, and we have the expertise in-house so we can pick up partial pieces and make something complete.”

According to Walsh, the biggest challenge contractors face is finding products that interact and work together.

“Revit is great for the design, but it doesn’t have the capabilities to communicate the scheduling and planning that goes with fabrication, extraction and construction. So what we’re really working on and focusing on is collaboration across multiple parts of our business, or multiple pieces of it from engineering to fabrication to field install logistics. Trying to tie it all together so that everybody working on a project knows exactly what the plan is and when it’s going to be delivered. The biggest trend and the biggest challenge is trying to get people that are specialized in all different aspects of the industry to collaborate.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!